Каталог Iscar токарный инструмент 2017 - страница 8

Навигация

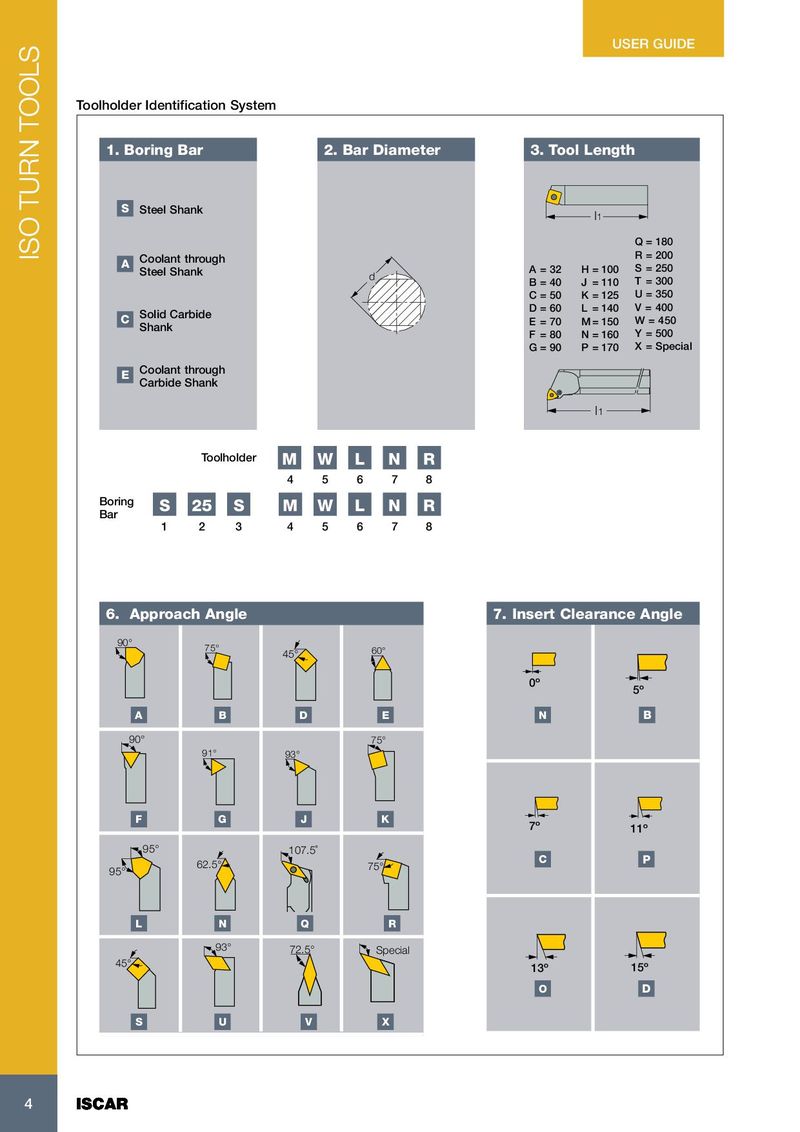

USER GUIDE Toolholder Identification System 1. Boring Bar 2. Bar Diameter 3. Tool Length S Steel Shank I1 Q = 180 ISO TURN TOOLS ISO TURN TOOLS Coolant through R = 200 A Steel Shank A = 32 H = 100 S = 250 d B = 40 J = 110 T = 300 C = 50 K = 125 U = 350 D = 60 L = 140 V = 400 Solid Carbide C E = 70 M = 150 W = 450 Shank F = 80 N = 160 Y = 500 G = 90 P = 170 X = Special Coolant through E Carbide Shank I1 Toolholder M W L N R 4 5 6 7 8 Boring S 25 S M W L N R Bar 1 2 3 4 5 6 7 8 6. Approach Angle 7. Insert Clearance Angle 90° 75° 60° 45° 0º 5º A B D E N B 90° 75° 91° 93° F G J K 7º 11º 95° 107.5˚ C P 62.5° 75° 95° L N Q R 93° 72.5° Special 45° 13º 15º O D S U V X 4 4 4 ISCAR ISCAR ISCAR

Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar расточные системы 2022

Каталог Iscar расточные системы 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar вращающийся инструмент 2017

Каталог Iscar вращающийся инструмент 2017