Каталог Iscar новые продукты 2018 - страница 76

Навигация

Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022 Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017

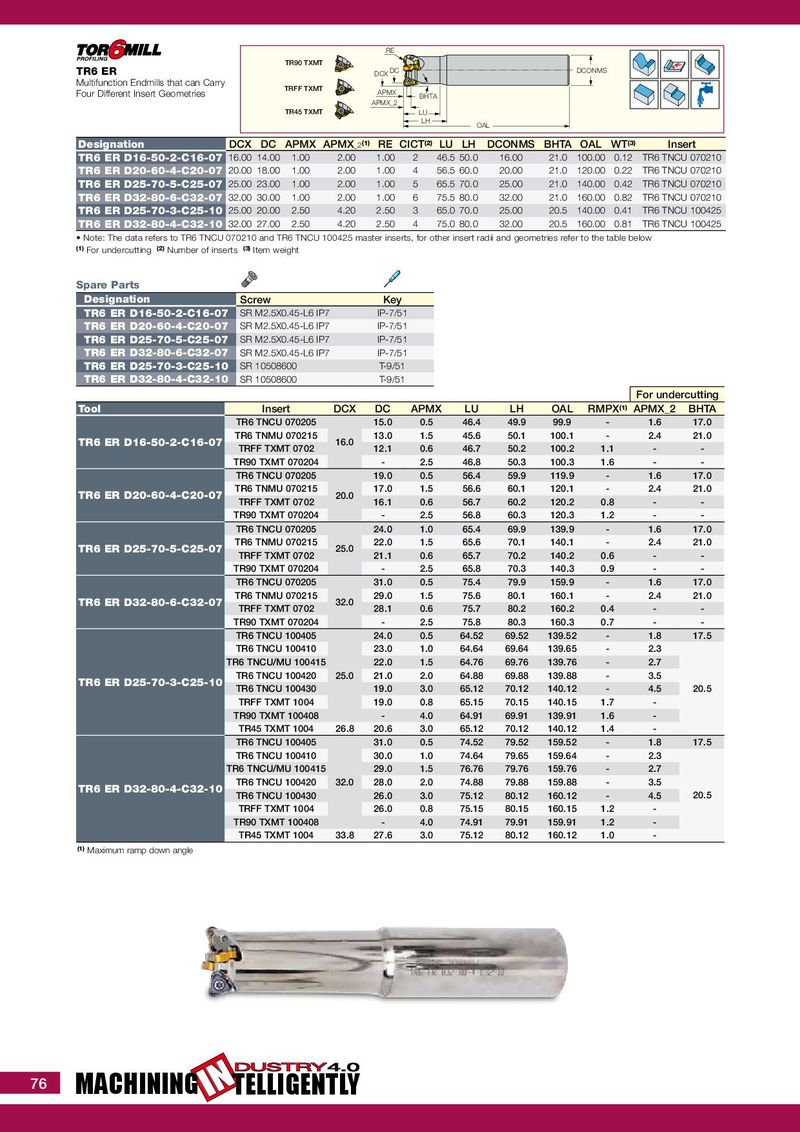

F O R I N T E R N A L U S E O N L Y • S U B J E C T T O C H A N G E RE TR90 TXMT TR6 ER DCX DC DCONMS Multifunction Endmills that can Carry TRFF TXMT Four Different Insert Geometries APMX BHTA APMX_2 TR45 TXMT LU LH OAL Designation DCX DC APMX APMX _2 (1) RE CICT (2) LU LH DCONMS BHTA OAL WT (3) Insert TR6 ER D16-50-2-C16-07 16.00 14.00 1.00 2.00 1.00 2 46.5 50.0 16.00 21.0 100.00 0.12 TR6 TNCU 070210 TR6 ER D20-60-4-C20-07 20.00 18.00 1.00 2.00 1.00 4 56.5 60.0 20.00 21.0 120.00 0.22 TR6 TNCU 070210 TR6 ER D25-70-5-C25-07 25.00 23.00 1.00 2.00 1.00 5 65.5 70.0 25.00 21.0 140.00 0.42 TR6 TNCU 070210 TR6 ER D32-80-6-C32-07 32.00 30.00 1.00 2.00 1.00 6 75.5 80.0 32.00 21.0 160.00 0.82 TR6 TNCU 070210 TR6 ER D25-70-3-C25-10 25.00 20.00 2.50 4.20 2.50 3 65.0 70.0 25.00 20.5 140.00 0.41 TR6 TNCU 100425 TR6 ER D32-80-4-C32-10 32.00 27.00 2.50 4.20 2.50 4 75.0 80.0 32.00 20.5 160.00 0.81 TR6 TNCU 100425 • Note: The data refers to TR6 TNCU 070210 and TR6 TNCU 100425 master inserts, for other insert radii and geometries refer to the table below (1) For undercutting (2) Number of inserts (3) Item weight Spare Parts Designation Screw Key TR6 ER D16-50-2-C16-07 SR M2.5X0.45-L6 IP7 IP-7/51 TR6 ER D20-60-4-C20-07 SR M2.5X0.45-L6 IP7 IP-7/51 TR6 ER D25-70-5-C25-07 SR M2.5X0.45-L6 IP7 IP-7/51 TR6 ER D32-80-6-C32-07 SR M2.5X0.45-L6 IP7 IP-7/51 TR6 ER D25-70-3-C25-10 SR 10508600 T-9/51 TR6 ER D32-80-4-C32-10 SR 10508600 T-9/51 For undercutting Tool Insert DCX DC APMX LU LH OAL RMPX (1) APMX_2 BHTA TR6 TNCU 070205 15.0 0.5 46.4 49.9 99.9 - 1.6 17.0 TR6 TNMU 070215 13.0 1.5 45.6 50.1 100.1 - 2.4 21.0 TR6 ER D16-50-2-C16-07 16.0 TRFF TXMT 0702 12.1 0.6 46.7 50.2 100.2 1.1 - - TR90 TXMT 070204 - 2.5 46.8 50.3 100.3 1.6 - - TR6 TNCU 070205 19.0 0.5 56.4 59.9 119.9 - 1.6 17.0 TR6 TNMU 070215 17.0 1.5 56.6 60.1 120.1 - 2.4 21.0 TR6 ER D20-60-4-C20-07 20.0 TRFF TXMT 0702 16.1 0.6 56.7 60.2 120.2 0.8 - - TR90 TXMT 070204 - 2.5 56.8 60.3 120.3 1.2 - - TR6 TNCU 070205 24.0 1.0 65.4 69.9 139.9 - 1.6 17.0 TR6 TNMU 070215 22.0 1.5 65.6 70.1 140.1 - 2.4 21.0 TR6 ER D25-70-5-C25-07 25.0 TRFF TXMT 0702 21.1 0.6 65.7 70.2 140.2 0.6 - - TR90 TXMT 070204 - 2.5 65.8 70.3 140.3 0.9 - - TR6 TNCU 070205 31.0 0.5 75.4 79.9 159.9 - 1.6 17.0 TR6 TNMU 070215 29.0 1.5 75.6 80.1 160.1 - 2.4 21.0 TR6 ER D32-80-6-C32-07 32.0 TRFF TXMT 0702 28.1 0.6 75.7 80.2 160.2 0.4 - - TR90 TXMT 070204 - 2.5 75.8 80.3 160.3 0.7 - - TR6 TNCU 100405 24.0 0.5 64.52 69.52 139.52 - 1.8 17.5 TR6 TNCU 100410 23.0 1.0 64.64 69.64 139.65 - 2.3 TR6 TNCU/MU 100415 22.0 1.5 64.76 69.76 139.76 - 2.7 TR6 TNCU 100420 25.0 21.0 2.0 64.88 69.88 139.88 - 3.5 TR6 ER D25-70-3-C25-10 TR6 TNCU 100430 19.0 3.0 65.12 70.12 140.12 - 4.5 20.5 TRFF TXMT 1004 19.0 0.8 65.15 70.15 140.15 1.7 - TR90 TXMT 100408 - 4.0 64.91 69.91 139.91 1.6 - TR45 TXMT 1004 26.8 20.6 3.0 65.12 70.12 140.12 1.4 - TR6 TNCU 100405 31.0 0.5 74.52 79.52 159.52 - 1.8 17.5 TR6 TNCU 100410 30.0 1.0 74.64 79.65 159.64 - 2.3 TR6 TNCU/MU 100415 29.0 1.5 76.76 79.76 159.76 - 2.7 TR6 TNCU 100420 32.0 28.0 2.0 74.88 79.88 159.88 - 3.5 TR6 ER D32-80-4-C32-10 TR6 TNCU 100430 26.0 3.0 75.12 80.12 160.12 - 4.5 20.5 TRFF TXMT 1004 26.0 0.8 75.15 80.15 160.15 1.2 - TR90 TXMT 100408 - 4.0 74.91 79.91 159.91 1.2 - TR45 TXMT 1004 33.8 27.6 3.0 75.12 80.12 160.12 1.0 - (1) Maximum ramp down angle DUSTRY 4.0 76 MACHINING IN TELLIGENTLY