Каталог Iscar новые продукты 2018 - страница 53

Навигация

Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022 Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017

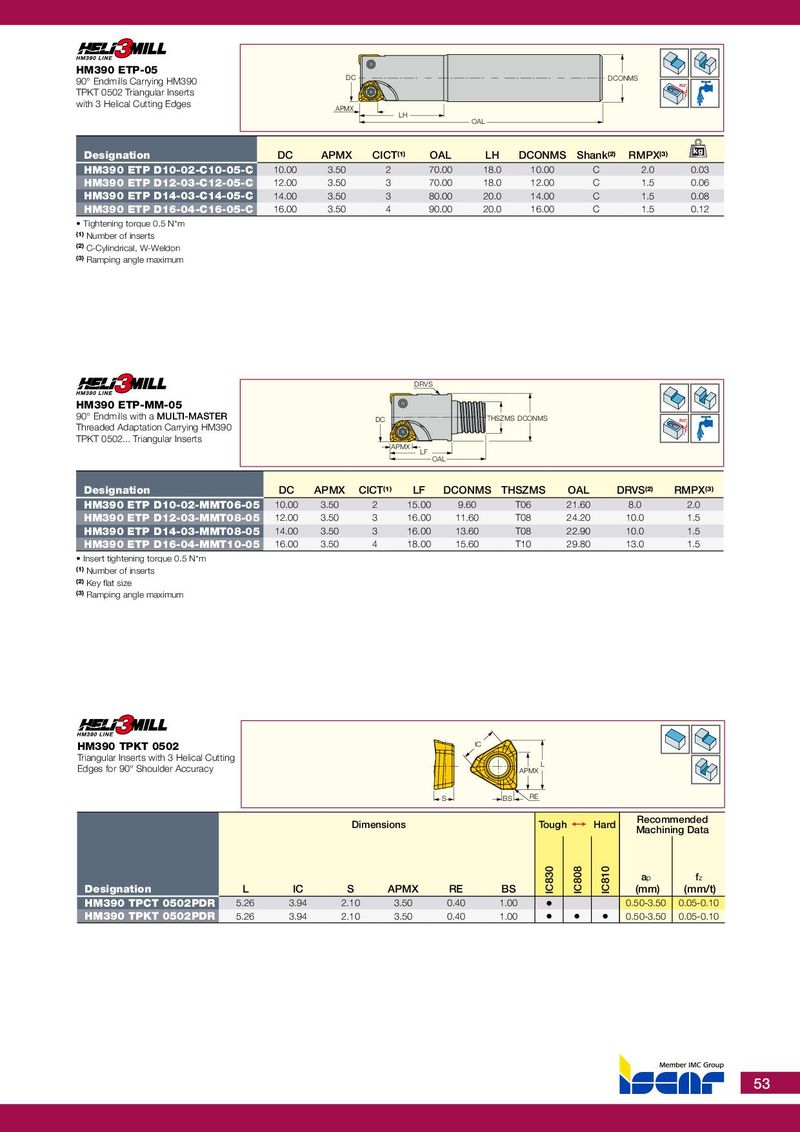

F O R I N T E R N A L U S E O N L Y • S U B J E C T T O C H A N G E F O R I N T E R N A L U S E O N L Y • S U B J E C T T O C H A N G E HM390 ETP-05 DC 90° Endmills Carrying HM390 DCONMS Rd° TPKT 0502 Triangular Inserts with 3 Helical Cutting Edges APMX LH OAL Designation DC APMX CICT (1) OAL LH DCONMS Shank (2) RMPX (3) kg HM390 ETP D10-02-C10-05-C 10.00 3.50 2 70.00 18.0 10.00 C 2.0 0.03 HM390 ETP D12-03-C12-05-C 12.00 3.50 3 70.00 18.0 12.00 C 1.5 0.06 HM390 ETP D14-03-C14-05-C 14.00 3.50 3 80.00 20.0 14.00 C 1.5 0.08 HM390 ETP D16-04-C16-05-C 16.00 3.50 4 90.00 20.0 16.00 C 1.5 0.12 • Tightening torque 0.5 N*m (1) Number of inserts (2) C-Cylindrical, W-Weldon (3) Ramping angle maximum DRVS HM390 ETP-MM-05 90° Endmills with a MULTI-MASTER DC THSZMS DCONMS Rd° Threaded Adaptation Carrying HM390 TPKT 0502... Triangular Inserts APMX LF OAL Designation DC APMX CICT (1) LF DCONMS THSZMS OAL DRVS (2) RMPX (3) HM390 ETP D10-02-MMT06-05 10.00 3.50 2 15.00 9.60 T06 21.60 8.0 2.0 HM390 ETP D12-03-MMT08-05 12.00 3.50 3 16.00 11.60 T08 24.20 10.0 1.5 HM390 ETP D14-03-MMT08-05 14.00 3.50 3 16.00 13.60 T08 22.90 10.0 1.5 HM390 ETP D16-04-MMT10-05 16.00 3.50 4 18.00 15.60 T10 29.80 13.0 1.5 • Insert tightening torque 0.5 N*m (1) Number of inserts (2) Key flat size (3) Ramping angle maximum HM390 TPKT 0502 IC Triangular Inserts with 3 Helical Cutting L Edges for 90° Shoulder Accuracy APMX S BS RE Recommended Dimensions Tough 1 Hard Machining Data a p f z Designation L IC S APMX RE BS IC830 IC808 IC810 (mm) (mm/t) HM390 TPCT 0502PDR 5.26 3.94 2.10 3.50 0.40 1.00 • 0.50-3.50 0.05-0.10 HM390 TPKT 0502PDR 5.26 3.94 2.10 3.50 0.40 1.00 • • • 0.50-3.50 0.05-0.10 53