Каталог Iscar новые продукты 2018 - страница 48

Навигация

Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022 Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017

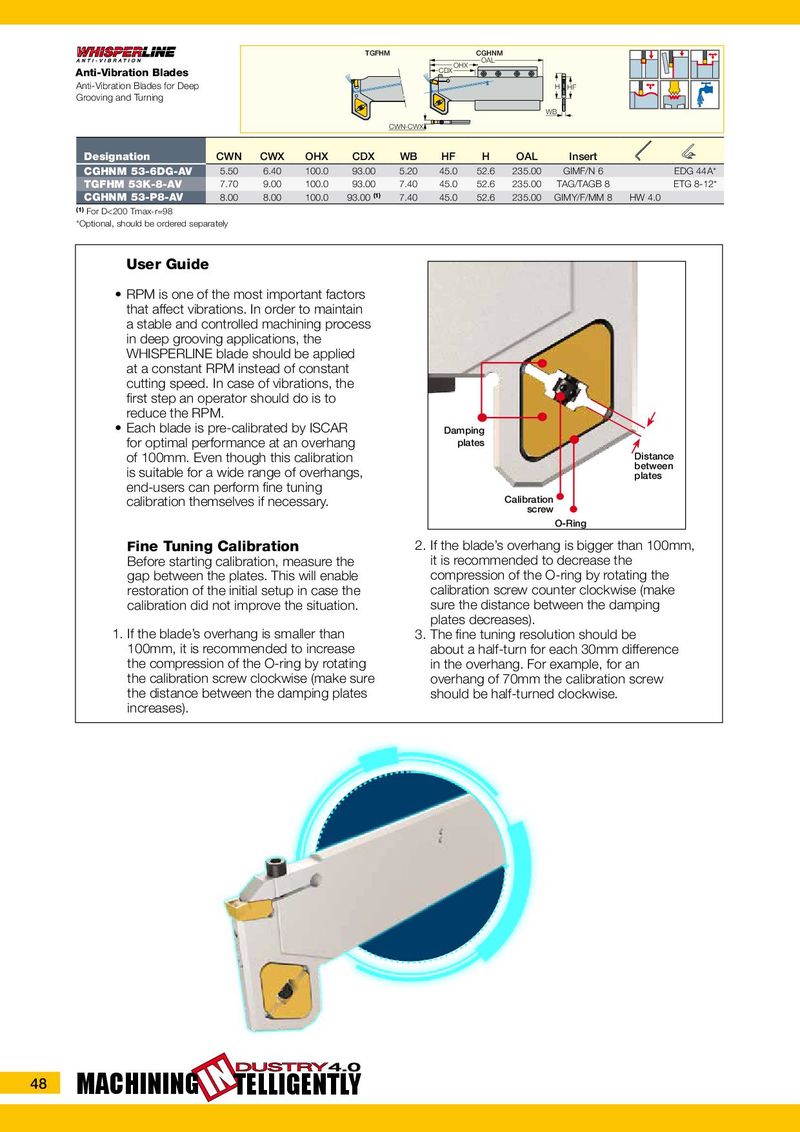

F O R I N T E R N A L U S E O N L Y • S U B J E C T T O C H A N G E TGFHM CGHNM OAL OHX Anti-Vibration Blades CDX Anti-Vibration Blades for Deep H HF Grooving and Turning WB CWN-CWX Designation CWN CWX OHX CDX WB HF H OAL Insert CGHNM 53-6DG-AV 5.50 6.40 100.0 93.00 5.20 45.0 52.6 235.00 GIMF/N 6 EDG 44A* TGFHM 53K-8-AV 7.70 9.00 100.0 93.00 7.40 45.0 52.6 235.00 TAG/TAGB 8 ETG 8-12* CGHNM 53-P8-AV 8.00 8.00 100.0 93.00 (1) 7.40 45.0 52.6 235.00 GIMY/F/MM 8 HW 4.0 (1) For D<200 Tmax-r=98 *Optional, should be ordered separately User Guide • RPM is one of the most important factors that affect vibrations. In order to maintain a stable and controlled machining process in deep grooving applications, the WHISPERLINE blade should be applied at a constant RPM instead of constant cutting speed. In case of vibrations, the first step an operator should do is to reduce the RPM. • Each blade is pre-calibrated by ISCAR Damping for optimal performance at an overhang plates of 100mm. Even though this calibration Distance between is suitable for a wide range of overhangs, plates end-users can perform fine tuning calibration themselves if necessary. Calibration screw O-Ring Fine Tuning Calibration 2. If the blade’s overhang is bigger than 100mm, Before starting calibration, measure the it is recommended to decrease the gap between the plates. This will enable compression of the O-ring by rotating the restoration of the initial setup in case the calibration screw counter clockwise (make calibration did not improve the situation. sure the distance between the damping plates decreases). 1. If the blade’s overhang is smaller than 3. The fine tuning resolution should be 100mm, it is recommended to increase about a half-turn for each 30mm difference the compression of the O-ring by rotating in the overhang. For example, for an the calibration screw clockwise (make sure overhang of 70mm the calibration screw the distance between the damping plates should be half-turned clockwise. increases). DUSTRY 4.0 48 MACHINING IN TELLIGENTLY