Каталог Iscar новые продукты 2018 - страница 41

Навигация

Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022 Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017

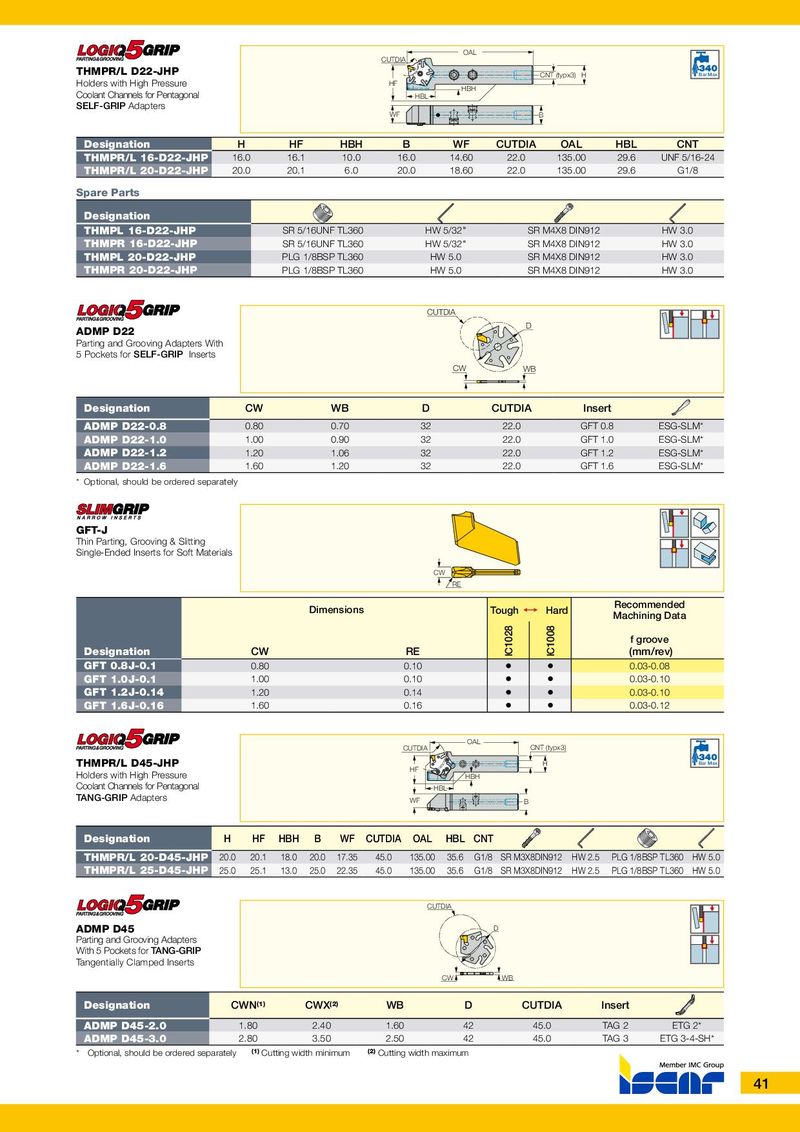

F O R I N T E R N A L U S E O N L Y • S U B J E C T T O C H A N G E F O R I N T E R N A L U S E O N L Y • S U B J E C T T O C H A N G E OAL CUTDIA THMPR/L D22-JHP CNT (typx3) H Bar Max Holders with High Pressure HF HBH Coolant Channels for Pentagonal HBL SELF-GRIP Adapters WF B Designation H HF HBH B WF CUTDIA OAL HBL CNT THMPR/L 16-D22-JHP 16.0 16.1 10.0 16.0 14.60 22.0 135.00 29.6 UNF 5/16-24 THMPR/L 20-D22-JHP 20.0 20.1 6.0 20.0 18.60 22.0 135.00 29.6 G1/8 Spare Parts Designation THMPL 16-D22-JHP SR 5/16UNF TL360 HW 5/32" SR M4X8 DIN912 HW 3.0 THMPR 16-D22-JHP SR 5/16UNF TL360 HW 5/32" SR M4X8 DIN912 HW 3.0 THMPL 20-D22-JHP PLG 1/8BSP TL360 HW 5.0 SR M4X8 DIN912 HW 3.0 THMPR 20-D22-JHP PLG 1/8BSP TL360 HW 5.0 SR M4X8 DIN912 HW 3.0 CUTDIA D ADMP D22 Parting and Grooving Adapters With 5 Pockets for SELF-GRIP Inserts CW WB Designation CW WB D CUTDIA Insert ADMP D22-0.8 0.80 0.70 32 22.0 GFT 0.8 ESG-SLM* ADMP D22-1.0 1.00 0.90 32 22.0 GFT 1.0 ESG-SLM* ADMP D22-1.2 1.20 1.06 32 22.0 GFT 1.2 ESG-SLM* ADMP D22-1.6 1.60 1.20 32 22.0 GFT 1.6 ESG-SLM* * Optional, should be ordered separately GFT-J Thin Parting, Grooving & Slitting Single-Ended Inserts for Soft Materials CW RE Recommended Dimensions Tough 1 Hard Machining Data f groove Designation CW RE IC1028 IC1008 (mm/rev) GFT 0.8J-0.1 0.80 0.10 • • 0.03-0.08 GFT 1.0J-0.1 1.00 0.10 • • 0.03-0.10 GFT 1.2J-0.14 1.20 0.14 • • 0.03-0.10 GFT 1.6J-0.16 1.60 0.16 • • 0.03-0.12 OAL CUTDIA CNT (typx3) THMPR/L D45-JHP H Bar Max HF Holders with High Pressure HBH Coolant Channels for Pentagonal HBL TANG-GRIP Adapters WF B Designation H HF HBH B WF CUTDIA OAL HBL CNT THMPR/L 20-D45-JHP 20.0 20.1 18.0 20.0 17.35 45.0 135.00 35.6 G1/8 SR M3X8DIN912 HW 2.5 PLG 1/8BSP TL360 HW 5.0 THMPR/L 25-D45-JHP 25.0 25.1 13.0 25.0 22.35 45.0 135.00 35.6 G1/8 SR M3X8DIN912 HW 2.5 PLG 1/8BSP TL360 HW 5.0 CUTDIA ADMP D45 D Parting and Grooving Adapters With 5 Pockets for TANG-GRIP Tangentially Clamped Inserts CW WB Designation CWN (1) CWX (2) WB D CUTDIA Insert ADMP D45-2.0 1.80 2.40 1.60 42 45.0 TAG 2 ETG 2* ADMP D45-3.0 2.80 3.50 2.50 42 45.0 TAG 3 ETG 3-4-SH* * Optional, should be ordered separately (1) Cutting width minimum (2) Cutting width maximum 41