Каталог Iscar новые продукты 2018 - страница 35

Навигация

Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022 Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017

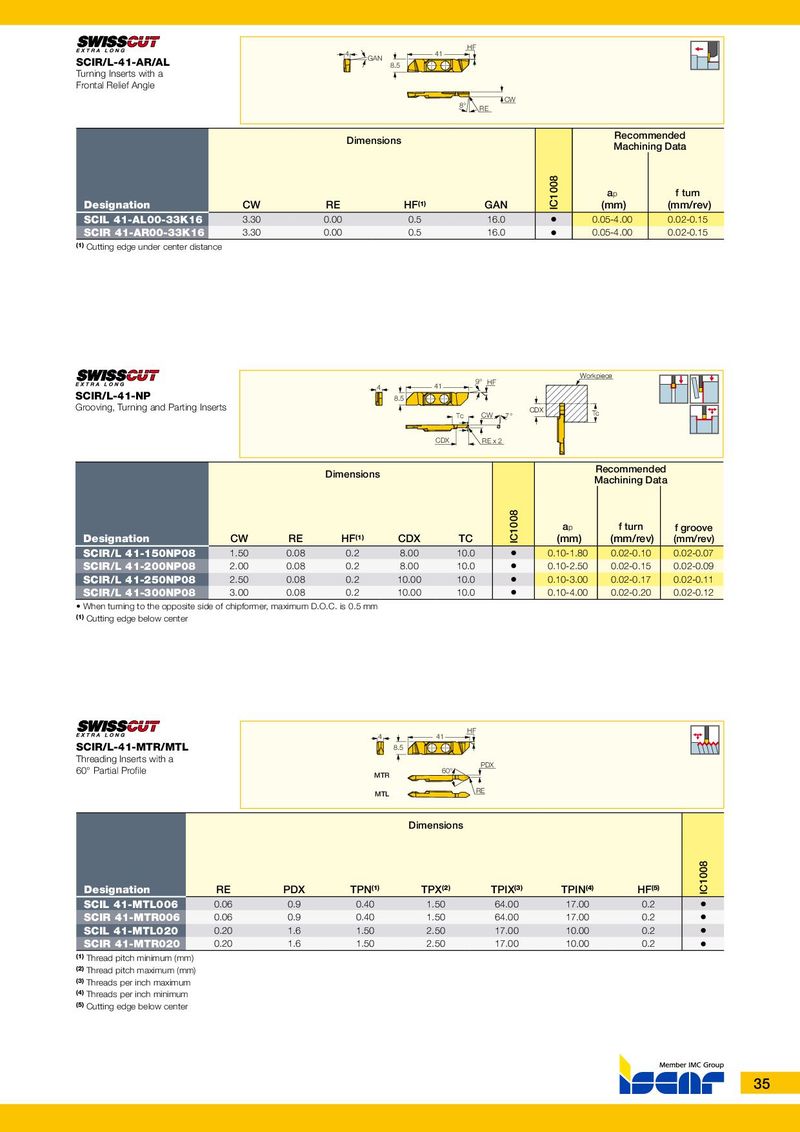

F O R I N T E R N A L U S E O N L Y • S U B J E C T T O C H A N G E F O R I N T E R N A L U S E O N L Y • S U B J E C T T O C H A N G E HF 4 41 GAN SCIR/L-41-AR/AL 8.5 Turning Inserts with a Frontal Relief Angle CW 8° RE Recommended Dimensions Machining Data a p f turn Designation CW RE HF (1) GAN IC1008 (mm) (mm/rev) SCIL 41-AL00-33K16 3.30 0.00 0.5 16.0 • 0.05-4.00 0.02-0.15 SCIR 41-AR00-33K16 3.30 0.00 0.5 16.0 • 0.05-4.00 0.02-0.15 (1) Cutting edge under center distance Workpiece 9° HF 4 41 SCIR/L-41-NP 8.5 Grooving, Turning and Parting Inserts CDX Tc CW 7° Tc CDX RE x 2 Recommended Dimensions Machining Data a p f turn f groove Designation CW RE HF (1) CDX TC IC1008 (mm) (mm/rev) (mm/rev) SCIR/L 41-150NP08 1.50 0.08 0.2 8.00 10.0 • 0.10-1.80 0.02-0.10 0.02-0.07 SCIR/L 41-200NP08 2.00 0.08 0.2 8.00 10.0 • 0.10-2.50 0.02-0.15 0.02-0.09 SCIR/L 41-250NP08 2.50 0.08 0.2 10.00 10.0 • 0.10-3.00 0.02-0.17 0.02-0.11 SCIR/L 41-300NP08 3.00 0.08 0.2 10.00 10.0 • 0.10-4.00 0.02-0.20 0.02-0.12 • When turning to the opposite side of chipformer, maximum D.O.C. is 0.5 mm (1) Cutting edge below center HF 4 41 SCIR/L-41-MTR/MTL 8.5 Threading Inserts with a PDX 60° Partial Profile 60° MTR MTL RE Dimensions Designation RE PDX TPN (1) TPX (2) TPIX (3) TPIN (4) HF (5) IC1008 SCIL 41-MTL006 0.06 0.9 0.40 1.50 64.00 17.00 0.2 • SCIR 41-MTR006 0.06 0.9 0.40 1.50 64.00 17.00 0.2 • SCIL 41-MTL020 0.20 1.6 1.50 2.50 17.00 10.00 0.2 • SCIR 41-MTR020 0.20 1.6 1.50 2.50 17.00 10.00 0.2 • (1) Thread pitch minimum (mm) (2) Thread pitch maximum (mm) (3) Threads per inch maximum (4) Threads per inch minimum (5) Cutting edge below center 35