Каталог Iscar новые продукты 2018 - страница 33

Навигация

Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022 Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017

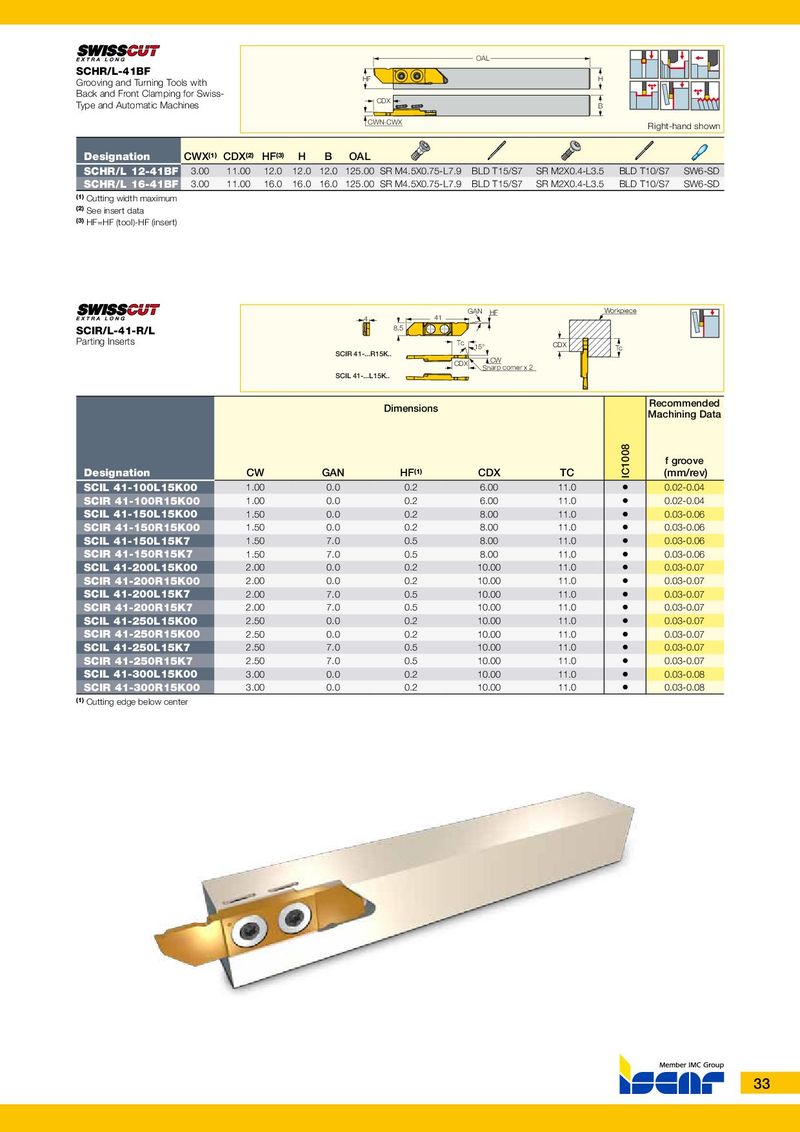

F O R I N T E R N A L U S E O N L Y • S U B J E C T T O C H A N G E F O R I N T E R N A L U S E O N L Y • S U B J E C T T O C H A N G E OAL SCHR/L-41BF HF H Grooving and Turning Tools with Back and Front Clamping for Swiss- CDX Type and Automatic Machines B CWN-CWX Right-hand shown Designation CWX (1) CDX (2) HF (3) H B OAL SCHR/L 12-41BF 3.00 11.00 12.0 12.0 12.0 125.00 SR M4.5X0.75-L7.9 BLD T15/S7 SR M2X0.4-L3.5 BLD T10/S7 SW6-SD SCHR/L 16-41BF 3.00 11.00 16.0 16.0 16.0 125.00 SR M4.5X0.75-L7.9 BLD T15/S7 SR M2X0.4-L3.5 BLD T10/S7 SW6-SD (1) Cutting width maximum (2) See insert data (3) HF=HF (tool)-HF (insert) GAN HF Workpiece 4 41 SCIR/L-41-R/L 8.5 Parting Inserts Tc 15° CDX Tc SCIR 41-...R15K.. CDX CW Sharp corner x 2 SCIL 41-...L15K.. Recommended Dimensions Machining Data f groove Designation CW GAN HF (1) CDX TC IC1008 (mm/rev) SCIL 41-100L15K00 1.00 0.0 0.2 6.00 11.0 • 0.02-0.04 SCIR 41-100R15K00 1.00 0.0 0.2 6.00 11.0 • 0.02-0.04 SCIL 41-150L15K00 1.50 0.0 0.2 8.00 11.0 • 0.03-0.06 SCIR 41-150R15K00 1.50 0.0 0.2 8.00 11.0 • 0.03-0.06 SCIL 41-150L15K7 1.50 7.0 0.5 8.00 11.0 • 0.03-0.06 SCIR 41-150R15K7 1.50 7.0 0.5 8.00 11.0 • 0.03-0.06 SCIL 41-200L15K00 2.00 0.0 0.2 10.00 11.0 • 0.03-0.07 SCIR 41-200R15K00 2.00 0.0 0.2 10.00 11.0 • 0.03-0.07 SCIL 41-200L15K7 2.00 7.0 0.5 10.00 11.0 • 0.03-0.07 SCIR 41-200R15K7 2.00 7.0 0.5 10.00 11.0 • 0.03-0.07 SCIL 41-250L15K00 2.50 0.0 0.2 10.00 11.0 • 0.03-0.07 SCIR 41-250R15K00 2.50 0.0 0.2 10.00 11.0 • 0.03-0.07 SCIL 41-250L15K7 2.50 7.0 0.5 10.00 11.0 • 0.03-0.07 SCIR 41-250R15K7 2.50 7.0 0.5 10.00 11.0 • 0.03-0.07 SCIL 41-300L15K00 3.00 0.0 0.2 10.00 11.0 • 0.03-0.08 SCIR 41-300R15K00 3.00 0.0 0.2 10.00 11.0 • 0.03-0.08 (1) Cutting edge below center 33