Каталог Iscar новые продукты 2018 - страница 110

Навигация

Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022 Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017

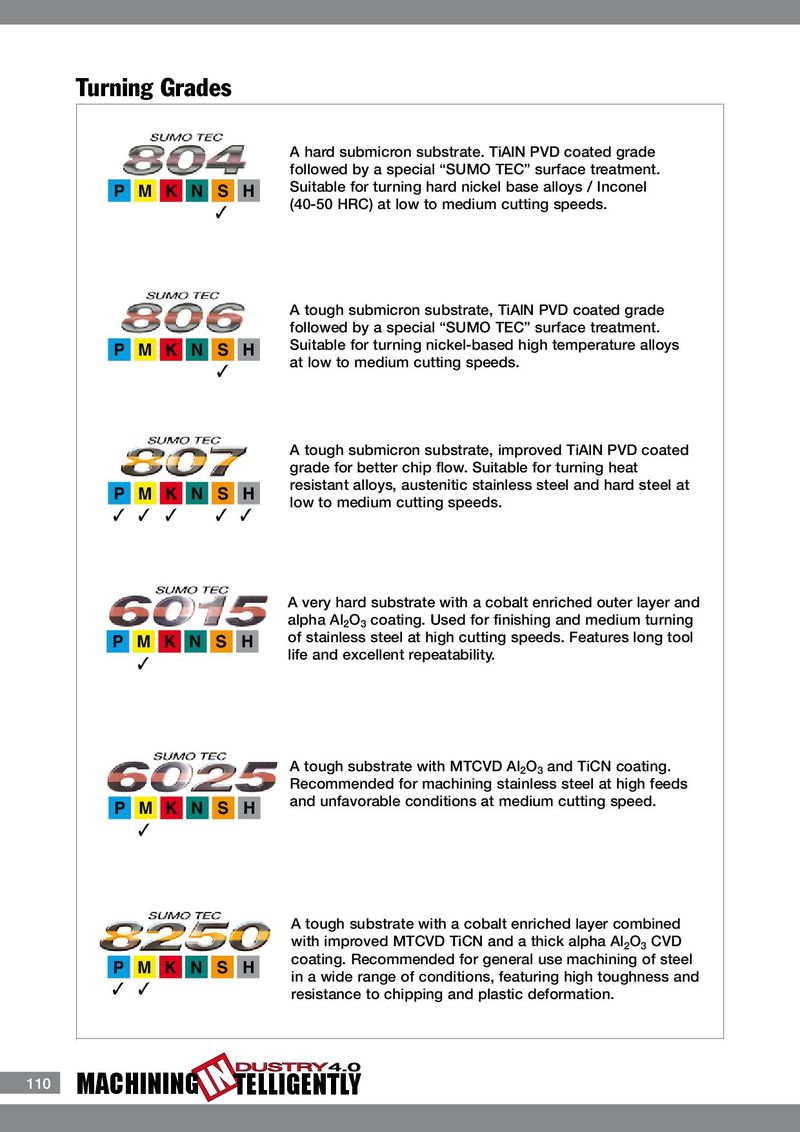

F O R I N T E R N A L U S E O N L Y • S U B J E C T T O C H A N G E Turning Grades A hard submicron substrate. TiAlN PVD coated grade followed by a special “SUMO TEC” surface treatment. Suitable for turning hard nickel base alloys / Inconel P M K N S H (40-50 HRC) at low to medium cutting speeds. 3 A tough submicron substrate, TiAlN PVD coated grade followed by a special “SUMO TEC” surface treatment. Suitable for turning nickel-based high temperature alloys P M K N S H at low to medium cutting speeds. 3 A tough submicron substrate, improved TiAlN PVD coated grade for better chip flow. Suitable for turning heat resistant alloys, austenitic stainless steel and hard steel at P M K N S H low to medium cutting speeds. 3 3 3 3 3 A very hard substrate with a cobalt enriched outer layer and alpha Al 2 O 3 coating. Used for finishing and medium turning of stainless steel at high cutting speeds. Features long tool P M K N S H life and excellent repeatability. 3 A tough substrate with MTCVD Al 2 O 3 and TiCN coating. Recommended for machining stainless steel at high feeds and unfavorable conditions at medium cutting speed. P M K N S H 3 A tough substrate with a cobalt enriched layer combined with improved MTCVD TiCN and a thick alpha Al 2 O 3 CVD coating. Recommended for general use machining of steel P M K N S H in a wide range of conditions, featuring high toughness and 3 3 resistance to chipping and plastic deformation. DUSTRY 4.0 110 MACHINING IN TELLIGENTLY