Каталог Iscar высокоточные развертки и метчики 2022 - страница 46

Навигация

Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Руководство Iscar режущий инструмент в производстве штампов и пресс-форм

Руководство Iscar режущий инструмент в производстве штампов и пресс-форм Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022

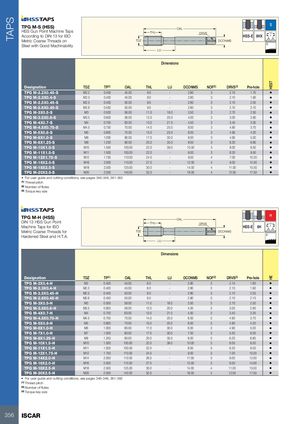

TAPS HESTHE TPG M-S (HSS) SOAL HSS Gun Point Machine Taps THL DRVS 60˚ According to DIN 13 for ISO HSS-E 6HX P Metric Coarse Threads on TDZ DCONMS Steel with Good Machinability B LU Dimensions Designation TDZ TP(1) OAL THL LU DCONMS NOF(2) DRVS(3) Pre-hole TPG M-2.2X0.45-S M2.2 0.450 45.00 8.0 - 2.80 3 2.10 1.75 • TPG M-2.3X0.4-S M2.3 0.400 45.00 8.0 - 2.80 3 2.10 1.90 • TPG M-2.5X0.45-S M2.5 0.450 50.00 9.0 - 2.80 3 2.10 2.05 • TPG M-2.6X0.45-S M2.6 0.450 50.00 9.0 - 2.80 3 2.10 2.10 • TPG M-3X0.5-S M3 0.500 56.00 11.0 18.0 3.50 3 2.70 2.50 • TPG M-3.5X0.6-S M3.5 0.600 56.00 12.0 20.0 4.00 3 3.00 2.90 • TPG M-4X0.7-S M4 0.700 63.00 13.0 21.0 4.50 3 3.40 3.30 • TPG M-4.5X0.75-S M4.5 0.750 70.00 14.0 25.0 6.00 3 4.90 3.70 • TPG M-5X0.8-S M5 0.800 70.00 15.0 25.0 6.00 3 4.90 4.20 • TPG M-6X1.0-S M6 1.000 80.00 17.0 30.0 6.00 3 4.90 5.00 • TPG M-8X1.25-S M8 1.250 90.00 20.0 35.0 8.00 3 6.20 6.80 • TPG M-10X1.5-S M10 1.500 100.00 22.0 39.0 10.00 3 8.00 8.50 • TPG M-11X1.5-S M11 1.500 100.00 22.0 - 8.00 3 6.20 9.50 • TPG M-12X1.75-S M12 1.750 110.00 24.0 - 9.00 4 7.00 10.20 • TPG M-16X2.0-S M16 2.000 110.00 27.0 - 12.00 4 9.00 14.00 • TPG M-18X2.5-S M18 2.500 125.00 30.0 - 14.00 4 11.00 15.50 • TPG M-20X2.5-S M20 2.500 140.00 32.0 - 16.00 4 12.00 17.50 • • For user guide and cutting conditions, see pages 346-348, 361-382 (1) Thread pitch (2) Number of flutes (3) Torque key size TPG M-H (HSS) HOAL DIN 13 HSS Gun Point THL DRVS 60˚ Machine Taps for ISO HSS-E 6H P Metric Coarse Threads for TDZ DCONMS Hardened Steel and H.T.A. B LU Dimensions Designation TDZ TP(1) OAL THL LU DCONMS NOF(2) DRVS(3) Pre-hole TPG M-2X0.4-H M2 0.400 45.00 8.0 - 2.80 3 2.10 1.60 • TPG M-2.3X0.4-H M2.3 0.400 45.00 8.0 - 2.80 3 2.10 1.90 • TPG M-2.5X0.45-H M2.5 0.450 50.00 9.0 - 2.80 3 2.10 2.05 • TPG M-2.6X0.45-H M2.6 0.450 50.00 9.0 - 2.80 3 2.10 2.10 • TPG M-3X0.5-H M3 0.500 56.00 11.0 18.0 3.50 3 2.70 2.50 • TPG M-3.5X0.6-H M3.5 0.600 56.00 12.0 20.0 4.00 3 3.00 2.90 • TPG M-4X0.7-H M4 0.700 63.00 13.0 21.0 4.50 3 3.40 3.30 • TPG M-4.5X0.75-H M4.5 0.750 70.00 14.0 25.0 6.00 3 4.90 3.70 • TPG M-5X0.8-H M5 0.800 70.00 15.0 25.0 6.00 3 4.90 4.20 • TPG M-6X1.0-H M6 1.000 80.00 17.0 30.0 6.00 3 4.90 5.00 • TPG M-7X1.0-H M7 1.000 80.00 17.0 30.0 7.00 3 5.50 6.00 • TPG M-8X1.25-H M8 1.250 90.00 20.0 35.0 8.00 3 6.20 6.80 • TPG M-10X1.5-H M10 1.500 100.00 22.0 39.0 10.00 3 8.00 8.50 • TPG M-11X1.5-H M11 1.500 100.00 22.0 - 8.00 3 6.20 9.50 • TPG M-12X1.75-H M12 1.750 110.00 24.0 - 9.00 3 7.00 10.20 • TPG M-14X2.0-H M14 2.000 110.00 26.0 - 11.00 3 9.00 12.00 • TPG M-16X2.0-H M16 2.000 110.00 27.0 - 12.00 3 9.00 14.00 • TPG M-18X2.5-H M18 2.500 125.00 30.0 - 14.00 4 11.00 15.50 • TPG M-20X2.5-H M20 2.500 140.00 32.0 - 16.00 4 12.00 17.50 • • For user guide and cutting conditions, see pages 346-348, 361-382 (1) Thread pitch (2) Number of flutes (3) Torque key size 356 ISCAR