Каталог Iscar высокоточные развертки и метчики 2022 - страница 36

Навигация

Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Руководство Iscar режущий инструмент в производстве штампов и пресс-форм

Руководство Iscar режущий инструмент в производстве штампов и пресс-форм Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022

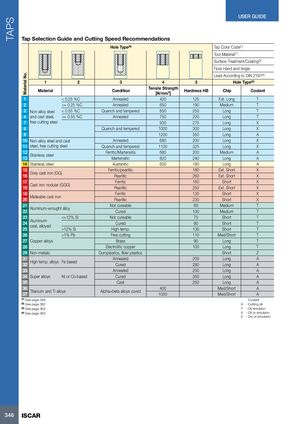

TAPS Material No. USER GUIDE Tap Selection Guide and Cutting Speed Recommendations Hole Type(4) Tap Color Code(1) Tool Material(1) Surface Treatment/Coating(2) Flute Hand and Angle Lead According to DIN 2197(3) 1 2 3 4 5 Hole Type(4) Material Condition Tensile Strength[N/mm2]Hardness HB Chip Coolant 1 < 0.25 %C Annealed 420 125 Ext. Long T 2 >= 0.25 %C Annealed 650 190 Medium T 3 Non-alloy steel < 0.55 %C Quench and tempered 850 250 Long T 4 and cast steel, >= 0.55 %C Annealed 750 220 Long T 7 free cutting steel 930 275 Long X 8 Quench and tempered 1000 300 Long X 9 1200 350 Long A 10 Non-alloy steel and cast Annealed 680 200 Long X 11 steel, free cutting steel Quench and tempered 1100 325 Long X 1213 Stainless steel Ferritic/Martensitis 680 200 Medium AMartensitic820240LongA 14 Stainless steel Austenitic 600 180 Long A 1516 Grey cast iron (GG) Ferritic/pearliticPearlitic 180 Ext. Short X260Ext. ShortX 1718 Cast iron nodular (GGG) FerriticPearlitic 160 Short X250Ext. ShortX 1920 Malleable cast iron FerriticPearlitic 130 Short X230ShortX 2122 Aluminum-wrought alloy Not cureableCured 60 Medium T100MediumT 23 <=12% Si Not cureable 75 Short T 24 Aluminum-cast, alloyed Cured 90 Short T 25 >12% Si High temp. 130 Short T 26 >1% Pb Free cutting 110 Med/Short T 27 Copper alloys Brass 90 Long T 28 Electrolitic copper 100 Long T 29 Non-metalic Duroplastics, fiber plastics Short Z 3132 High temp. alloys Fe based AnnealedCured 200 Long A280LongA 33 Annealed 250 Long A 34 Super alloys Ni or Co based Cured 350 Long A 35 Cast 250 Long A 3637 Titanium and Ti alloys 400Alpha+beta alloys cured1050Med/Short AMed/ShortA (1) See page 348 Coolant (2) See page 362 A - Cutting oil (3) See page 363 T - Oil emulsion (4) See page 363 X - Oil or emulsion Z - Dry or emulsion 346 ISCAR