Каталог Iscar высокоточные развертки и метчики 2022 - страница 32

Навигация

Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Руководство Iscar режущий инструмент в производстве штампов и пресс-форм

Руководство Iscar режущий инструмент в производстве штампов и пресс-форм Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022

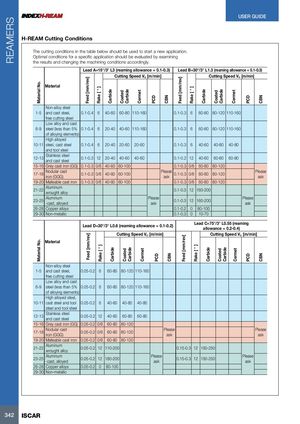

REAMERS Material No.Material No. Feed [mm/rev]Feed [mm/rev] Rake [ ° ]Rake [ ° ] CarbideCarbide Coated CarbideCoatedCarbide CermetCermet PCDPCD CBNCBN Feed [mm/rev] Feed [mm/rev] Rake [ ° ] Rake [ ° ] Carbide Carbide Coated CarbideCoated Carbide CermetCermet PCDPCD CBNCBN USER GUIDE H-REAM Cutting Conditions The cutting conditions in the table below should be used to start a new application. Optimal conditions for a specific application should be evaluated by examining the results and changing the machining conditions accordingly. Lead A=15°/3° L3 (reaming allowance = 0.1-0.3) Lead B=30°/3° L1.3 (reaming allowance = 0.1-0.3) Cutting Speed Vc [m/min] Cutting Speed Vc [m/min] Material Non-alloy steel 1-5 and cast steel, 0.1-0.4 6 40-60 60-80 110-160 0.1-0.3 6 60-80 80-120 110-160 free cutting steel Low alloy and cast 6-9 steel (less than 5% 0.1-0.4 6 20-40 40-60 110-160 0.1-0.3 6 60-80 80-120 110-160 of alloying elements) High alloyed 10-11 steel, cast steel 0.1-0.4 6 20-40 20-60 20-60 0.1-0.3 6 40-60 40-80 40-80 and tool steel 12-13 Stainless steeland cast steel0.1-0.3 12 20-40 40-60 40-60 0.1-0.2 12 40-60 60-80 60-80 15-16 Grey cast iron (GG) 0.1-0.3 0/6 40-60 60-100 0.1-0.3 0/6 60-80 80-120 17-18 Nodular castiron (GGG)0.1-0.3 0/6 40-60 60-100 Pleaseask0.1-0.3 0/6 60-80 80-120 Pleaseask 19-20 Malleable cast iron 0.1-0.3 0/6 40-60 60-100 0.1-0.3 0/6 60-80 80-120 21-22 Aluminumwrought alloy 0.1-0.3 12 160-200 23-25 Aluminum-cast, alloyed Pleaseask 0.1-0.3 12 160-200 Pleaseask 26-28 Copper alloys 0.1-0.2 0 80-100 29-30 Non-metallic 0.1-0.3 0 10-70 Lead D=30°/3° L0.6 (reaming allowance = 0.1-0.2) Lead C=75°/3° L0.55 (reamingallowance = 0.2-0.4) Cutting Speed Vc [m/min] Cutting Speed Vc [m/min] Material Non-alloy steel 1-5 and cast steel, 0.05-0.2 6 60-80 80-120 110-160 free cutting steel Low alloy and cast 6-9 steel (less than 5% 0.05-0.2 6 60-80 80-120 110-160 of alloying elements) High alloyed steel, 10-11 cast steel and tool 0.05-0.2 6 40-60 40-80 40-80 steel and tool steel 12-13 Stainless steeland cast steel0.05-0.2 12 40-60 60-80 60-80 15-16 Grey cast iron (GG) 0.05-0.2 0/6 60-80 80-120 17-18 Nodular castiron (GGG)0.05-0.2 0/6 60-80 80-120 Pleaseask Pleaseask 19-20 Malleable cast iron 0.05-0.2 0/6 60-80 80-120 21-22 Aluminumwrought alloy 0.05-0.2 12 110-200 0.15-0.3 12 150-250 23-25 Aluminum-cast, alloyed0.05-0.2 12 180-200 Pleaseask 0.15-0.3 12 150-250 Pleaseask 26-28 Copper alloys 0.05-0.2 0 80-100 29-30 Non-metallic 342 ISCAR