Каталог Iscar торцевые фрезы 2022 - страница 71

Навигация

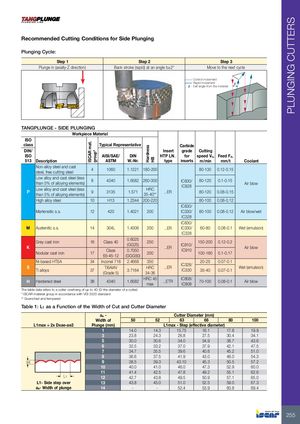

ISCAR mat. group* Hardness HB PLUNGING CUTTERS Recommended Cutting Conditions for Side Plunging Plunging Cycle: Step 1 Step 2 Step 3 Plunge in (axially-Z direction) Back stroke (rapid) at an angle b≥2° Move to the next cycle Control movement Rapid movement β β - Exit angle from the material TANGPLUNGE - SIDE PLUNGING Workpiece Material ISO class Typical Representative Carbide DIN/ Insert grade Cutting ISO AISI/SAE/ DIN HTP LN… for speed Vc, Feed Fz, 513 Description ASTM W.-Nr. type inserts m/min mm/t Coolant Non-alloy steel and caststeel, free cutting steel4 1060 1.1221 180-200 80-130 0.12-0.15 Low alloy and cast steel (lessthan 5% of alloying elements)8PLow alloy and cast steel (lessthan 5% of alloying elements)9434031351.6582260-300IC830/80-1200.1-0.151.571HRC35-40**…ERIC92880-1200.08-0.15Air blow High alloy steel 10 H13 1.2344 200-220 80-100 0.08-0.12 IC830/ Martensitic s.s. 12 420 1.4021 200 IC330/ 80-100 0.08-0.12 Air blow/wet IC328 IC830/ M Austenitic s.s. 14 304L 1.4306 200 …ER IC330/ 60-80 0.08-0.1 Wet (emulsion) IC328 Grey cast ironKNodular cast iron 16 Class 40 0.6025(GG25) 25017Class65-45-120.7050(GGG50)200…ERIC810/150-200 0.12-0.2IC910100-1800.1-0.17Air blow Ni-based HTSASTi alloys 34 Inconel 718 2.4668 35037Ti6Al4V(Grade 5)3.7164HRC34-36…ERIC328/IC33020-2535-400.07-0.10.07-0.1Wet (emulsion) H Hardened steel 38 4340 1.6582 HRC 45max …ETR IC808/IC90870-100 0.08-0.1 Air blow The table data refers to a cutter overhang of up to 4D (D-the diameter of a cutter) * ISCAR material group in accordance with VDI 3323 standard ** Quenched and tempered Table 1: L1 as a Function of the Width of Cut and Cutter Diameter ae - Cutter Diameter (mm) Width of 50 52 63 66 80 100 L1max = 2x Dxae-ae2 Plunge (mm) L1max - Step (effective diameter) 1 14.0 14.3 15.75 16.1 17.8 19.9 3 23.8 24.3 26.8 27.5 30.4 34.1 5 30.0 30.6 34.0 34.9 38.7 43.6 6 32.5 33.2 37.0 37.9 42.1 47.5 7 34.7 35.5 39.6 40.6 45.2 51.0 8 36.6 37.5 41.9 43.0 48.0 54.3 ae 9 38.5 39.3 43.10 45.3 50.5 57.2 10 40.0 41.0 46.0 47.3 52.9 60.0 11 41.4 42.5 47.8 49.2 55.1 62.6 L1 12 42.7 43.8 49.5 50.9 57.1 65.0 L1- Side step over 13 43.8 45.0 51.0 52.5 59.0 67.3 ae- Width of plunge 14 - - 52.4 53.9 60.8 69.4 255

Каталог Iscar сверла со сменной режущей частью 2022

Каталог Iscar сверла со сменной режущей частью 2022 Каталог Iscar державки и пластины для нарезания резьбы 2022

Каталог Iscar державки и пластины для нарезания резьбы 2022 Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar отрезка 2022

Каталог Iscar отрезка 2022 Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017 Каталог Iscar монолитные сверла 2022

Каталог Iscar монолитные сверла 2022