Каталог Iscar токарные пластины ISO 2022 - страница 76

Навигация

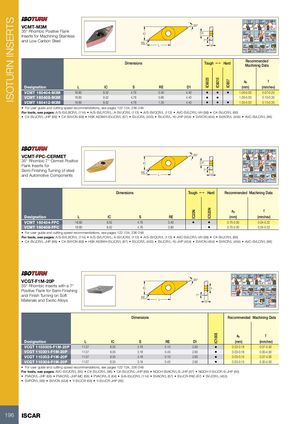

ISOTURN INSERTS IC20N IC6025IC520N IC6015IC1008 IC807 52° 50° 70°MAX MAX MAX VCMT-M3M 35° 91° 93° 72.5º 35° Rhombic Positive FlankInserts for Machining Stainless IC D1 31°MAX 30°MAX and Low Carbon Steel 7° 112° 117.5° 93ºRE L S 48°MAX 35°MAX 95º 95º 107.5º Dimensions Tough 1 Hard RecommendedMachining Data ap f Designation L IC S RE D1 (mm) (mm/rev) VCMT 160404-M3M 16.60 9.52 4.76 0.40 4.40 • • • 1.00-5.00 0.07-0.25 VCMT 160408-M3M 16.60 9.52 4.76 0.80 4.40 • • 1.00-5.00 0.10-0.30 VCMT 160412-M3M 16.60 9.52 4.76 1.20 4.40 • • • 1.00-5.00 0.13-0.35 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A/S-SVLBCR/L (114) • A/S-SVLFCR/L; A-SVUCR/L (113) • A/S-SVQCR/L (113) • AVC-SVLCR/L-VH (98) • C#-SVJCR/L (66) • C#-SVJCR/L-JHP (66) • C#-SVVCN (69) • HSK A63WH-SVJCR/L (67) • SVJCR/L (453) • SVJCR/L-16-JHP (454) • SVVCN (454) • SVXCR/L (454) • AVC-SVLCR/L (96) 52° 50° 70°MAX MAX MAX VCMT-FPC-CERMET 35° 91° 93° 72.5º 35° Rhombic 7° Cermet PositiveFlank Inserts for IC D1 31°MAX 30°MAX Semi-Finishing Turning of steel 7° 112° 117.5° 93ºRE and Automotive Components L S 48°MAX 35°MAX 95º 95º 107.5º Dimensions Tough 1 Hard Recommended Machining Data ap f Designation L IC S RE (mm) (mm/rev) VCMT 160404-FPC 16.60 9.52 4.76 0.40 • • 0.70-2.00 0.04-0.22 VCMT 160408-FPC 16.60 9.52 4.76 0.80 • 0.70-2.00 0.04-0.22 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A/S-SVLBCR/L (114) • A/S-SVLFCR/L; A-SVUCR/L (113) • A/S-SVQCR/L (113) • AVC-SVLCR/L-VH (98) • C#-SVJCR/L (66) • C#-SVJCR/L-JHP (66) • C#-SVVCN (69) • HSK A63WH-SVJCR/L (67) • SVJCR/L (453) • SVJCR/L-16-JHP (454) • SVVCN (454) • SVXCR/L (454) • AVC-SVLCR/L (96) 52° 50° 70°MAX 31° MAX MAX MAX VCGT-F1M-20P 35° 91° 93° 72.5º 112° 35° Rhombic Inserts with a 7°Positive Flank for Semi-Finishing IC D1 30° 48° 35°MAXMAXMAX and Finish Turning on SoftMaterials and Exotic Alloys RE L 7° 117.5° 93º 95º 107.5º142ºS95º 93º Dimensions Recommended Machining Data ap f Designation L IC S RE D1 (mm) (mm/rev) VCGT 1103005-F1M-20P 11.07 6.35 3.18 0.10 2.90 • 0.03-0.18 0.07-4.50 VCGT 110301-F1M-20P 11.07 6.35 3.18 0.40 2.90 • 0.03-0.18 0.30-4.50 VCGT 110302-F1M-20P 11.07 6.35 3.18 0.10 2.90 • 0.03-0.15 0.07-4.00 VCGT 110304-F1M-20P 11.07 6.35 3.18 0.40 2.90 • 0.03-0.15 0.30-4.00 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: AVC-SVUCR/L (95) • C#-SVJCR/L (66) • C#-SVJCR/L-JHP (66) • NQCH-SVACR/L-S-JHP (67) • NQCH-Y-SVJCR-S-JHP (65) • PVACR/L-JHP (68) • PVACR/L-JHP-MC (68) • PVACR/L-S (64) • S/A-SVJCR/L (114) • SVACR/L (67) • SVJCR-PAD (67) • SVJCR/L (453) • SVPCR/L (69) • SVVCN (454) • Y-SVJCR (65) • Y-SVJCR-JHP (65) 196 ISCAR

Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar инструмент для токарной обработки

Каталог Iscar инструмент для токарной обработки Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022 Каталог Iscar инструментальные блоки

Каталог Iscar инструментальные блоки Каталог Iscar торцевые фрезы 2022

Каталог Iscar торцевые фрезы 2022