Каталог Iscar токарные пластины ISO 2022 - страница 64

Навигация

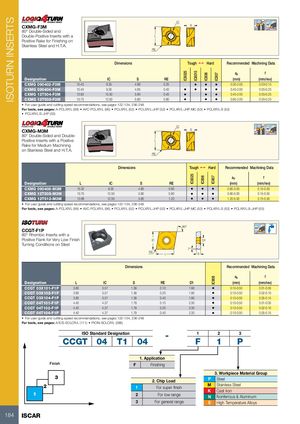

ISOTURN INSERTS IC6025 IC6025 IC6015 IC806 IC806 IC807IC908 IC807 IC 95º CXMG-F3M S 95º95º 80° Double-Sided and Double-Positive Inserts with a L Positive Rake for Finishing on Stainless Steel and H.T.A. RE Dimensions Tough 1 Hard Recommended Machining Data ap f Designation L IC S RE (mm) (mm/rev) CXMG 090402-F3M 10.40 9.35 4.66 0.20 • • • 0.30-2.00 0.03-0.15 CXMG 090404-F3M 10.40 9.35 4.65 0.40 • • • • 0.40-2.00 0.05-0.25 CXMG 12T504-F3M 13.83 12.50 5.80 0.40 • • • 0.40-2.00 0.05-0.25 CXMG 12T508-F3M 13.75 12.50 5.80 0.80 • • • 0.80-2.00 0.05-0.25 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A-PCLXR/L (99) • AVC-PCLXR/L (96) • PCLXR/L (52) • PCLXR/L-JHP (52) • PCLXR/L-JHP-MC (53) • PCLXR/L-S (52) • PCLXR/L-S-JHP (53) IC 95º CXMG-M3M S 95º95º 80° Double-Sided and Double- Positive Inserts with a Positive L Rake for Medium Machining on Stainless Steel and H.T.A. RE Dimensions Tough 1 Hard Recommended Machining Data ap f Designation L IC S RE (mm) (mm/rev) CXMG 090408-M3M 10.32 9.35 4.65 0.80 • • • 0.80-3.00 0.15-0.50 CXMG 12T508-M3M 13.75 12.50 5.80 0.80 • • • 0.80-5.00 0.15-0.50 CXMG 12T512-M3M 13.68 12.50 5.80 1.20 • • • 1.20-5.00 0.15-0.50 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A-PCLXR/L (99) • AVC-PCLXR/L (96) • PCLXR/L (52) • PCLXR/L-JHP (52) • PCLXR/L-JHP-MC (53) • PCLXR/L-S (52) • PCLXR/L-S-JHP (53) CCGT-F1P 80° 95º 80° Rhombic Inserts with a Positive Flank for Very Low Finish IC D1 Turning Conditions on Steel 7° RE L S Dimensions Recommended Machining Data ap f Designation L IC S RE D1 (mm) (mm/rev) CCGT 03X101-F1P 3.60 3.57 1.39 0.10 1.90 • 0.10-0.50 0.01-0.05 CCGT 03X102-F1P 3.60 3.57 1.39 0.20 1.90 • 0.10-0.50 0.02-0.10 CCGT 03X104-F1P 3.60 3.57 1.39 0.40 1.90 • 0.10-0.50 0.05-0.15 CCGT 04T101-F1P 4.40 4.37 1.79 0.10 2.30 • 0.10-0.50 0.01-0.05 CCGT 04T102-F1P 4.40 4.37 1.79 0.20 2.30 • 0.10-0.50 0.02-0.10 CCGT 04T104-F1P 4.40 4.37 1.79 0.40 2.30 • 0.10-0.50 0.05-0.15 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A/E/S-SCLCR/L (111) • PICIN-SCLCR/L (386) ISO Standard Designation - 1 2 3 CCGT 04 T1 04 F 1 P 1. Application Finish F Finishing 3. Workpiece Material Group 3 2. Chip Load P Steel 2 1 For super finish M Stainless Steel 1 K Cast Iron2For low rangeNNonferrous & Aluminum 3 For general range S High Temperature Alloys 184 ISCAR

Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar инструмент для токарной обработки

Каталог Iscar инструмент для токарной обработки Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022 Каталог Iscar инструментальные блоки

Каталог Iscar инструментальные блоки Каталог Iscar торцевые фрезы 2022

Каталог Iscar торцевые фрезы 2022