Каталог Iscar токарные пластины ISO 2022 - страница 48

Навигация

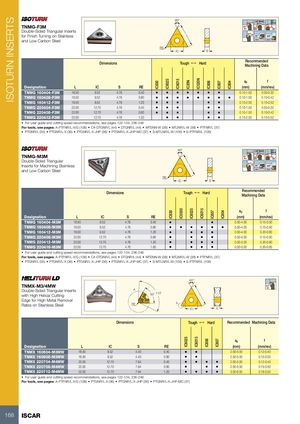

ISOTURN INSERTS IC830 IC6025 IC830 IC6015 IC5500 IC20NIC6025 IC6025 IC520NIC6015 IC6015 IC806IC806 IC807 IC807IC807 IC804 IC804 60° 22°MAX 55° MAX TNMG-F3M 91º 93º 60º Double-Sided Triangular Inserts for Finish Turning on Stainless L 91º 91º 95º and Low Carbon Steel RE IC S Dimensions Tough 1 Hard RecommendedMachining Data ap f Designation L IC S RE (mm) (mm/rev) TNMG 160404-F3M 16.50 9.52 4.76 0.40 • • • • • • • 0.10-1.50 0.05-0.32 TNMG 160408-F3M 16.50 9.52 4.76 0.80 • • • • • • • • 0.10-1.50 0.10-0.42 TNMG 160412-F3M 16.50 9.52 4.76 1.20 • • • • • 0.15-2.00 0.15-0.52 TNMG 220404-F3M 22.00 12.70 4.76 0.40 • • • • • 0.10-1.50 0.05-0.32 TNMG 220408-F3M 22.00 12.70 4.76 0.80 • • • • • 0.10-1.50 0.10-0.42 TNMG 220412-F3M 22.00 12.70 4.76 1.20 • • • • 0.15-2.00 0.15-0.52 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A-PTFNR/L-X/G (108) • C#-DTGNR/L (44) • DTGNR/L (44) • MTENN-W (38) • MTJNR/L-W (38) • PTFNR/L (37) • PTGNR/L (35) • PTGNR/L-X (36) • PTGNR/L-X-JHP (36) • PTGNR/L-X-JHP-MC (37) • S-MTLNR/L-W (109) • S-PTFNR/L (109) 60° 22°MAX 55° MAX TNMG-M3M 91º 93º 60º Double-Sided Triangular Inserts for Machining Stainless L 91º 91º 95º and Low Carbon Steel RE IC S Dimensions Tough 1 Hard RecommendedMachining Data ap f Designation L IC S RE (mm) (mm/rev) TNMG 160404-M3M 16.50 9.52 4.76 0.40 • • 0.50-4.00 0.15-0.50 TNMG 160408-M3M 16.50 9.52 4.76 0.80 • • • • • • 0.50-4.00 0.15-0.50 TNMG 160412-M3M 16.50 9.52 4.76 1.20 • • • • 0.50-4.00 0.20-0.60 TNMG 220408-M3M 22.00 12.70 4.76 0.80 • • • • 0.50-5.00 0.15-0.50 TNMG 220412-M3M 22.00 12.70 4.76 1.20 • • • • 0.50-5.00 0.20-0.60 TNMG 220416-M3M 22.00 12.70 4.76 1.60 • • • • 0.50-5.00 0.30-0.65 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A-PTFNR/L-X/G (108) • C#-DTGNR/L (44) • DTGNR/L (44) • MTENN-W (38) • MTJNR/L-W (38) • PTFNR/L (37) • PTGNR/L (35) • PTGNR/L-X (36) • PTGNR/L-X-JHP (36) • PTGNR/L-X-JHP-MC (37) • S-MTLNR/L-W (109) • S-PTFNR/L (109) 60° TNMX-M3/4MW 91º Double-Sided Triangular Inserts A with High Helical Cutting 60˚ 113˚ L Edge for High Metal Removal Rates on Stainless Steel RE A IC S Dimensions Tough 1 Hard Recommended Machining Data ap f Designation L IC S RE (mm) (mm/rev) TNMX 160604-M3MW 16.50 9.52 4.40 0.40 • • 2.00-5.00 0.12-0.40 TNMX 160608-M3MW 16.50 9.52 4.40 0.80 • • 2.50-5.50 0.15-0.50 TNMX 220704-M4MW 22.00 12.70 7.94 0.40 • • • • 2.00-5.00 0.12-0.40 TNMX 220708-M4MW 22.00 12.70 7.94 0.80 • • • 2.50-5.50 0.15-0.50 TNMX 220712-M4MW 22.00 12.70 7.94 1.20 • • • • 3.00-6.00 0.18-0.50 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A-PTFNR/L-X/G (108) • PTGNR/L-X (36) • PTGNR/L-X-JHP (36) • PTGNR/L-X-JHP-MC (37) 168 ISCAR

Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar инструмент для токарной обработки

Каталог Iscar инструмент для токарной обработки Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022 Каталог Iscar инструментальные блоки

Каталог Iscar инструментальные блоки Каталог Iscar торцевые фрезы 2022

Каталог Iscar торцевые фрезы 2022