Каталог Iscar токарные пластины ISO 2022 - страница 41

Навигация

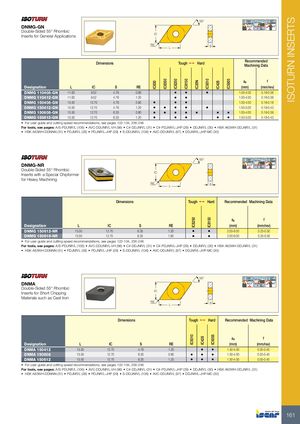

IC830 IC8350 IC8250 IC8150 IC8250IC5010 IC20N IC428 IC5010IC8150 IC5005 IC428 IC5005 ISOTURN INSERTS 55° 60°MAX 93º-95º 27°MAX DNMG-GN 62.5º 93º50º MAX Double-Sided 55° Rhombic Inserts for General Applications IC RE L S Dimensions Tough 1 Hard RecommendedMachining Data ap f Designation L IC S RE (mm) (mm/rev) DNMG 110408-GN 11.63 9.52 4.76 0.80 • • • 1.00-4.00 0.18-0.38 DNMG 110412-GN 11.63 9.52 4.76 1.20 • • 1.50-4.50 0.18-0.38 DNMG 150408-GN 15.50 12.70 4.76 0.80 • • • 1.00-4.00 0.18-0.18 DNMG 150412-GN 15.50 12.70 4.76 1.20 • • • • • 1.50-5.00 0.18-0.43 DNMG 150608-GN 15.50 12.70 6.35 0.80 • • • • • • • 1.00-4.00 0.18-0.38 DNMG 150612-GN 15.50 12.70 6.35 1.20 • • • • • 1.50-5.00 0.18-0.43 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A/S-PDUNR/L (106) • AVC-DDUNR/L-VH (98) • C#-DDJNR/L (31) • C#-PDJNR/L-JHP (29) • DDJNR/L (30) • HSK A63WH-DDJNR/L (31) • HSK A63WH-DDNNN (31) • PDJNR/L (28) • PDJNR/L-JHP (29) • S-DDUNR/L (106) • AVC-DDUNR/L (97) • DDJNR/L-JHP-MC (30) 55° 60°MAX 93º-95º 27°MAX DNMG-NR 62.5º 93º50º MAX Double-Sided 55° Rhombic Inserts with a Special Chipformer IC for Heavy Machining RE L S Dimensions Tough 1 Hard Recommended Machining Data ap f Designation L IC S RE (mm) (mm/rev) DNMG 150612-NR 15.50 12.70 6.35 1.20 • • 2.00-6.00 0.23-0.50 DNMG 150616-NR 15.50 12.70 6.35 1.60 • • 2.00-6.00 0.25-0.50 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A/S-PDUNR/L (106) • AVC-DDUNR/L-VH (98) • C#-DDJNR/L (31) • C#-PDJNR/L-JHP (29) • DDJNR/L (30) • HSK A63WH-DDJNR/L (31) • HSK A63WH-DDNNN (31) • PDJNR/L (28) • PDJNR/L-JHP (29) • S-DDUNR/L (106) • AVC-DDUNR/L (97) • DDJNR/L-JHP-MC (30) 55° 60° 27° MAX 93º-95º MAX DNMA 62.5º 93º50º MAX Double-Sided 55° Rhombic Inserts for Short Chipping IC Materials such as Cast Iron RE L S Dimensions Tough 1 Hard Recommended Machining Data ap f Designation L IC S RE (mm) (mm/rev) DNMA 150412 15.50 12.70 4.76 1.20 • • 1.50-4.00 0.05-0.40 DNMA 150608 15.50 12.70 6.35 0.80 • • • 1.50-4.00 0.03-0.40 DNMA 150612 15.50 12.70 6.35 1.20 • • • 1.50-4.00 0.05-0.40 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A/S-PDUNR/L (106) • AVC-DDUNR/L-VH (98) • C#-DDJNR/L (31) • C#-PDJNR/L-JHP (29) • DDJNR/L (30) • HSK A63WH-DDJNR/L (31) • HSK A63WH-DDNNN (31) • PDJNR/L (28) • PDJNR/L-JHP (29) • S-DDUNR/L (106) • AVC-DDUNR/L (97) • DDJNR/L-JHP-MC (30) 161

Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar инструмент для токарной обработки

Каталог Iscar инструмент для токарной обработки Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022 Каталог Iscar инструментальные блоки

Каталог Iscar инструментальные блоки Каталог Iscar торцевые фрезы 2022

Каталог Iscar торцевые фрезы 2022