Каталог Iscar токарные пластины ISO 2022 - страница 28

Навигация

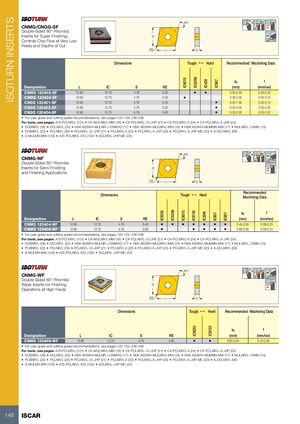

ISOTURN INSERTS IC8250 IC530N IC6015IC6015 IC520NIC8150IC8250 IC428IC20N IC8150 IC907IC807 IC907 80° 75° 95º CNMG/CNGG-SF 75º95º Double-Sided 80° Rhombic Inserts for Super-Finishing; IC 95º Controls Chip Flow at Very Low Feeds and Depths of Cut RE L S Dimensions Tough 1 Hard Recommended Machining Data ap f Designation L IC S RE (mm) (mm/rev) CNMG 120402-SF 12.90 12.70 4.76 0.20 • • 0.30-2.00 0.03-0.25 CNMG 120404-SF 12.90 12.70 4.76 0.40 • 0.30-2.00 0.05-0.25 CNGG 120401-SF 12.90 12.70 4.76 0.10 • 0.20-1.50 0.03-0.15 CNGG 120402-SF 12.90 12.70 4.76 0.20 • 0.30-2.00 0.03-0.20 CNGG 120404-SF 12.90 12.70 4.76 0.40 • 0.30-2.00 0.03-0.20 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A/S-PCLNR/L (101) • C#-MULNR/L-MW (16) • C#-PCLNR/L-12-JHP (21) • C#-PCLNR/L-X (24) • C#-PCLNR/L-X-JHP (24) • DCBNR/L (26) • DCLNR/L (25) • HSK A63WH-MULNR-J12MWX2 (17) • HSK A63WH-MULNR/L-MW (16) • HSK A63WH-MUMNN-MW (17) • MULNR/L-12MW (15) • PCBNR/L (22) • PCLNR/L (20) • PCLNR/L-12-JHP (21) • PCLNR/L-X (22) • PCLNR/L-X-JHP (23) • PCLNR/L-X-JHP-MC (23) • S-DCLNR/L (99) • S-MULNR-MW (105) • A/S-PCLNR/L-X/G (102) • DCLNR/L-JHP-MC (25) CNMG-NF 80° 75° 95º 95º95º Double-Sided 80° Rhombic Inserts for Semi-Finishing IC 75º and Finishing Applications RE L S Dimensions Tough 1 Hard RecommendedMachining Data ap f Designation L IC S RE (mm) (mm/rev) CNMG 120404-NF 12.90 12.70 4.76 0.40 • • • • • • • 0.40-3.50 0.08-0.25 CNMG 120408-NF 12.90 12.70 4.76 0.80 • • • • • 0.80-3.50 0.08-0.25 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A/S-PCLNR/L (101) • C#-MULNR/L-MW (16) • C#-PCLNR/L-12-JHP (21) • C#-PCLNR/L-X (24) • C#-PCLNR/L-X-JHP (24) • DCBNR/L (26) • DCLNR/L (25) • HSK A63WH-MULNR-J12MWX2 (17) • HSK A63WH-MULNR/L-MW (16) • HSK A63WH-MUMNN-MW (17) • MULNR/L-12MW (15) • PCBNR/L (22) • PCLNR/L (20) • PCLNR/L-12-JHP (21) • PCLNR/L-X (22) • PCLNR/L-X-JHP (23) • PCLNR/L-X-JHP-MC (23) • S-DCLNR/L (99) • S-MULNR-MW (105) • A/S-PCLNR/L-X/G (102) • DCLNR/L-JHP-MC (25) CNMG-WF 80° 75° 95º 95º95º Double-Sided 80° Rhombic Wiper Inserts for Finishing IC 75º Operations at High Feeds RE L S Dimensions Tough 1 Hard Recommended Machining Data ap f Designation L IC S RE (mm) (mm/rev) CNMG 120408-WF 12.90 12.70 4.76 0.80 • • 0.80-3.50 0.10-0.35 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A/S-PCLNR/L (101) • C#-MULNR/L-MW (16) • C#-PCLNR/L-12-JHP (21) • C#-PCLNR/L-X (24) • C#-PCLNR/L-X-JHP (24) • DCBNR/L (26) • DCLNR/L (25) • HSK A63WH-MULNR-J12MWX2 (17) • HSK A63WH-MULNR/L-MW (16) • HSK A63WH-MUMNN-MW (17) • MULNR/L-12MW (15) • PCBNR/L (22) • PCLNR/L (20) • PCLNR/L-12-JHP (21) • PCLNR/L-X (22) • PCLNR/L-X-JHP (23) • PCLNR/L-X-JHP-MC (23) • S-DCLNR/L (99) • S-MULNR-MW (105) • A/S-PCLNR/L-X/G (102) • DCLNR/L-JHP-MC (25) 148 ISCAR

Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar инструмент для токарной обработки

Каталог Iscar инструмент для токарной обработки Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022 Каталог Iscar инструментальные блоки

Каталог Iscar инструментальные блоки Каталог Iscar торцевые фрезы 2022

Каталог Iscar торцевые фрезы 2022