Каталог Iscar токарные пластины ISO 2022 - страница 123

Навигация

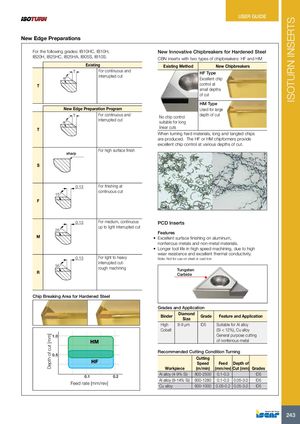

Depth of cut [mm] ISOTURN INSERTS USER GUIDE New Edge Preparations For the following grades: IB10HC, IB10H, New Innovative Chipbreakers for Hardened Steel IB20H, IB25HC, IB25HA, IB05S, IB10S. CBN inserts with two types of chipbreakers: HF and HM Existing Existing Method New Chipbreakers T For continuous and HF Type α° interrupted cut Excellent chip T control at small depths of cut HM Type New Edge Preparation Program Used for large T For continuous and No chip control depth of cut α° interrupted cut suitable for long T linear cuts When turning hard materials, long and tangled chips are produced. The HF or HM chipformers provide excellent chip control at various depths of cut. For high surface finish sharp S 0.13 For finishing at continuous cut 15° F 0.13 For medium, continuous PCD Inserts up to light interrupted cut 25° Features M • Excellent surface finishing on aluminum, nonferrous metals and non-metal materials. • Longer tool life in high speed machining, due to high wear resistance and excellent thermal conductivity. 0.13 For light to heavy Note: Not for use on steel or cast iron interrupted cut- 35° rough machiningR TungstenCarbide Chip Breaking Area for Hardened Steel Grades and Application Binder DiamondSize Grade Feature and Application High 8-9 µm ID5 Suitable for Al alloy Cobalt (Si < 12%), Cu alloy 1.0 General purpose cutting HM of nonferrous metal Recommended Cutting Condition Turning 0.5 Cutting HF Speed Feed Depth of Workpiece (m/min) (mm/rev) Cut (mm) Grades 0.1 0.2 Al alloy (4-9% Si) 800-2500 0.1-0.3 ID5 Al alloy (9-14% Si) 600-1280 0.1-0.3 0.05-3.0 ID5 Feed rate [mm/rev] Cu alloy 600-1000 0.05-0.2 0.05-3.0 ID5 243

Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar инструмент для токарной обработки

Каталог Iscar инструмент для токарной обработки Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022 Каталог Iscar инструментальные блоки

Каталог Iscar инструментальные блоки Каталог Iscar торцевые фрезы 2022

Каталог Iscar торцевые фрезы 2022