Каталог Iscar токарные пластины ISO 2022 - страница 114

Навигация

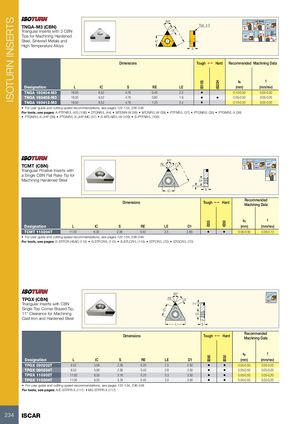

ISOTURN INSERTS IB10S IB55IB90 IB20H IB50IB50 60º 22°MAX TNGA-M3 (CBN)Triangular Inserts with 3 CBNTips for Machining Hardened Typ. x 3 91º91ºLE93ºL95º91º55°MAX Steel, Sintered Metals and IC 60º High Temperature Alloys S Dimensions Tough 1 Hard Recommended Machining Data ap f Designation L IC S RE LE (mm) (mm/rev) TNGA 160404-M3 16.50 9.52 4.76 0.40 2.2 • 0.10-0.50 0.05-0.30 TNGA 160408-M3 16.50 9.52 4.76 0.80 1.9 • • 0.05-0.50 0.05-0.30 TNGA 160412-M3 16.50 9.52 4.76 1.20 2.4 • 0.10-0.50 0.05-0.30 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A-PTFNR/L-X/G (108) • DTGNR/L (44) • MTENN-W (38) • MTJNR/L-W (38) • PTFNR/L (37) • PTGNR/L (35) • PTGNR/L-X (36) • PTGNR/L-X-JHP (36) • PTGNR/L-X-JHP-MC (37) • S-MTLNR/L-W (109) • S-PTFNR/L (109) 60° TCMT (CBN) RE LE 91º 91º 95º Triangular Positive Inserts witha Single CBN Flat Rake Tip for L 91º Machining Hardened Steel D1 7° IC S Dimensions Tough 1 Hard RecommendedMachining Data ap f Designation L IC S RE LE D1 (mm) (mm/rev) TCMT 110204T 11.00 6.35 2.38 0.40 3.5 2.85 • • 0.05-0.50 0.05-0.13 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: E-STFCR-HEAD (115) • S-STFCR/L (115) • S-STLCR/L (115) • STFCR/L (70) • STGCR/L (70) 60° TPGX (CBN) RE LE 91º Triangular Inserts with CBN 11° Single Top Corner Brazed Tip, IC 11° Clearance for Machining D1 Cast Iron and Hardened Steel L S Dimensions Tough 1 Hard RecommendedMachining Data ap f Designation L IC S RE LE D1 (mm) (mm/rev) TPGX 090202T 9.52 5.56 2.38 0.20 2.5 2.50 • • 0.05-0.50 0.03-0.20 TPGX 090204T 9.52 5.56 2.38 0.40 2.6 2.50 • • 0.05-0.50 0.03-0.20 TPGX 110302T 11.00 6.35 3.18 0.20 3.3 3.50 • • 0.05-0.50 0.03-0.20 TPGX 110304T 11.00 6.35 3.18 0.40 3.0 3.50 • • 0.05-0.50 0.03-0.20 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A/E-STFPR-X (117) • MG STFPR-X (117) 234 ISCAR

Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar инструмент для токарной обработки

Каталог Iscar инструмент для токарной обработки Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022 Каталог Iscar инструментальные блоки

Каталог Iscar инструментальные блоки Каталог Iscar торцевые фрезы 2022

Каталог Iscar торцевые фрезы 2022