Каталог Iscar токарные пластины ISO 2022 - страница 110

Навигация

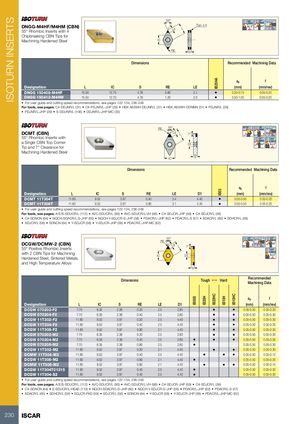

ISOTURN INSERTS IB05S IB20H IB25HAIB20HC IB55 IB10H IB10HC 55º 60° 27° MAX MAX 93º-95º DNGG-M4HF/M4HM (CBN)55° Rhombic Inserts with 4 Typ. x 4LEL 62.5º 93º 50ºMAX Chipbreaking CBN Tips for Machining Hardened Steel IC RE S Dimensions Recommended Machining Data ap f Designation L IC S RE LE (mm) (mm/rev) DNGG 150408-M4HF 15.50 12.70 4.76 0.80 2.1 • 0.20-0.75 0.05-0.20 DNGG 150412-M4HM 15.50 12.70 4.76 1.20 2.0 • 0.50-1.00 0.05-0.20 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: C#-DDJNR/L (31) • C#-PDJNR/L-JHP (29) • HSK A63WH-DDJNR/L (31) • HSK A63WH-DDNNN (31) • PDJNR/L (28) • PDJNR/L-JHP (29) • S-DDUNR/L (106) • DDJNR/L-JHP-MC (30) RE 55° 107.5° 29°MAX 93º-95º DCMT (CBN) LE L 7° 91° 50ºMAX 55° Rhombic Inserts with 27° 60° a Single CBN Top Corner MAX MAXD193º62.5º Tip and 7° Clearance for Machining Hardened Steel IC S Dimensions Recommended Machining Data ap f Designation L IC S RE LE D1 (mm) (mm/rev) DCMT 11T304T 11.60 9.52 3.97 0.40 3.4 4.40 • 0.05-0.50 0.05-0.20 DCMT 11T308T 11.60 9.52 3.97 0.80 3.1 4.40 • 0.05-0.50 0.05-0.20 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A/E/S-SDUCR/L (112) • AVC-SDUCR/L (95) • AVC-SDUCR/L-VH (98) • C#-SDJCR-JHP (59) • C#-SDJCR/L (59) • C#-SDNCN (64) • NQCH-SDACR/L-S-JHP (60) • NQCH-Y-SDJCR-S-JHP (58) • PDACR/L-JHP (62) • PDACR/L-S (57) • SDACR/L (60) • SDHCR/L (59) • SDJCR/L (58) • SDNCN (64) • Y-SDJCR (58) • Y-SDJCR-JHP (58) • PDACR/L-JHP-MC (62) 55°RE 29° 27°MAX93º-95ºMAX DCGW/DCMW-2 (CBN)55° Positive Rhombic Inserts LE L 7° 93º91°50ºMAX60° with 2 CBN Tips for Machining IC D1 MAX62.5º Hardened Steel, Sintered Metals and High Temperature Alloys S Dimensions Tough 1 Hard RecommendedMachining Data ap f Designation L IC S RE LE D1 (mm) (mm/rev) DCGW 070202-F2 7.70 6.35 2.38 0.20 2.5 2.80 • • 0.05-0.50 0.05-0.30 DCGW 070204-F2 7.70 6.35 2.38 0.40 2.5 2.80 • • 0.05-0.50 0.05-0.30 DCGW 11T302-F2 11.60 9.52 3.97 0.20 2.5 4.40 • • 0.05-0.50 0.05-0.30 DCGW 11T304-F2 11.60 9.52 3.97 0.40 2.5 4.40 • • 0.05-0.50 0.05-0.30 DCGW 11T308-F2 11.60 9.52 3.97 0.80 2.1 4.40 • • 0.05-0.50 0.05-0.30 DCGW 070202-M2 7.70 6.35 2.38 0.20 2.5 2.80 • • 0.05-0.50 0.05-0.30 DCGW 070204-M2 7.70 6.35 2.38 0.40 2.5 2.80 • • • 0.05-0.50 0.05-0.30 DCGW 070208-M2 7.70 6.35 2.38 0.80 2.5 2.80 • 0.05-0.50 0.05-0.30 DCGW 11T302-M2 11.60 9.52 3.97 0.20 2.1 4.40 • • 0.05-0.50 0.05-0.30 DCMW 11T304-M2 11.60 9.52 3.97 0.40 2.5 4.40 • • • 0.05-0.50 0.05-0.12 DCGW 11T308-M2 11.60 9.52 3.97 0.80 2.1 4.40 • 0.05-0.50 0.05-0.30 DCMW 11T308-M2 11.60 9.52 3.97 0.80 2.1 4.40 • • • 0.05-0.50 0.05-0.15 DCGW 11T304T01315 11.60 9.52 3.97 0.40 2.5 4.40 • 0.05-0.50 0.05-0.30 DCGW 11T304-S2 11.60 9.52 3.97 0.40 2.5 4.40 • 0.05-0.50 0.05-0.30 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A/E/S-SDUCR/L (112) • AVC-SDUCR/L (95) • AVC-SDUCR/L-VH (98) • C#-SDJCR-JHP (59) • C#-SDJCR/L (59) • C#-SDNCN (64) • E-SDUCR/L-HEAD (113) • NQCH-SDACR/L-S-JHP (60) • NQCH-Y-SDJCR-S-JHP (58) • PDACR/L-JHP (62) • PDACR/L-S (57) • SDACR/L (60) • SDHCR/L (59) • SDJCR-PAD (59) • SDJCR/L (58) • SDNCN (64) • Y-SDJCR (58) • Y-SDJCR-JHP (58) • PDACR/L-JHP-MC (62) 230 ISCAR

Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar инструмент для токарной обработки

Каталог Iscar инструмент для токарной обработки Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022 Каталог Iscar инструментальные блоки

Каталог Iscar инструментальные блоки Каталог Iscar торцевые фрезы 2022

Каталог Iscar торцевые фрезы 2022