Каталог Iscar сверла со сменной режущей частью 2022 - страница 34

Навигация

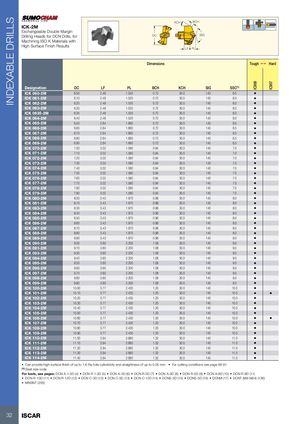

INDEXABLE DRILLS IC908 IC907 KCH BCH ICK-2M Exchangeable Double Margin Drilling Heads for DCN Drills, for DC SIG Machining ISO K Materials with High Surface Finish Results LF PL Dimensions Tough 1 Hard Designation DC LF PL BCH KCH SIG SSC(1) ICK 060-2M 6.00 2.48 1.520 0.72 30.0 140 6.0 • ICK 061-2M 6.10 2.48 1.520 0.72 30.0 140 6.0 • ICK 062-2M 6.20 2.48 1.520 0.72 30.0 140 6.0 • ICK 063-2M 6.30 2.48 1.520 0.72 30.0 140 6.0 • ICK 0635-2M 6.35 2.48 1.520 0.72 30.0 140 6.0 • ICK 064-2M 6.40 2.48 1.520 0.72 30.0 140 6.0 • ICK 065-2M 6.50 2.64 1.660 0.72 30.0 140 6.5 • ICK 066-2M 6.60 2.64 1.660 0.72 30.0 140 6.5 • ICK 067-2M 6.70 2.64 1.660 0.72 30.0 140 6.5 • ICK 068-2M 6.80 2.64 1.660 0.72 30.0 140 6.5 • ICK 069-2M 6.90 2.64 1.660 0.72 30.0 140 6.5 • ICK 070-2M 7.00 3.02 1.580 0.84 30.0 140 7.0 • ICK 071-2M 7.10 3.02 1.580 0.84 30.0 140 7.0 • ICK 072-2M 7.20 3.02 1.580 0.84 30.0 140 7.0 • ICK 073-2M 7.30 3.02 1.580 0.84 30.0 140 7.0 • ICK 074-2M 7.40 3.02 1.580 0.84 30.0 140 7.0 • ICK 075-2M 7.50 3.02 1.580 0.84 30.0 140 7.0 • ICK 076-2M 7.60 3.02 1.580 0.84 30.0 140 7.0 • ICK 077-2M 7.70 3.02 1.580 0.84 30.0 140 7.0 • ICK 078-2M 7.80 3.02 1.580 0.84 30.0 140 7.0 • ICK 079-2M 7.90 3.02 1.580 0.84 30.0 140 7.0 • ICK 080-2M 8.00 3.43 1.970 0.96 30.0 140 8.0 • ICK 081-2M 8.10 3.43 1.970 0.96 30.0 140 8.0 • ICK 083-2M 8.30 3.43 1.970 0.96 30.0 140 8.0 • ICK 084-2M 8.40 3.43 1.970 0.96 30.0 140 8.0 • ICK 085-2M 8.50 3.43 1.970 0.96 30.0 140 8.0 • ICK 086-2M 8.60 3.43 1.970 0.96 30.0 140 8.0 • ICK 087-2M 8.70 3.43 1.970 0.96 30.0 140 8.0 • ICK 088-2M 8.80 3.43 1.970 0.96 30.0 140 8.0 • ICK 089-2M 8.90 3.43 1.970 0.96 30.0 140 8.0 • ICK 090-2M 9.00 3.60 2.200 1.08 30.0 140 9.0 • ICK 091-2M 9.10 3.60 2.200 1.08 30.0 140 9.0 • ICK 093-2M 9.30 3.60 2.200 1.08 30.0 140 9.0 • ICK 094-2M 9.40 3.60 2.200 1.08 30.0 140 9.0 • ICK 095-2M 9.50 3.60 2.200 1.08 30.0 140 9.0 • ICK 096-2M 9.60 3.60 2.200 1.08 30.0 140 9.0 • ICK 097-2M 9.70 3.60 2.200 1.08 30.0 140 9.0 • ICK 098-2M 9.80 3.60 2.200 1.08 30.0 140 9.0 • ICK 099-2M 9.90 3.60 2.200 1.08 30.0 140 9.0 • ICK 100-2M 10.00 3.77 2.430 1.20 30.0 140 10.0 • ICK 101-2M 10.10 3.77 2.430 1.20 30.0 140 10.0 • • ICK 102-2M 10.20 3.77 2.430 1.20 30.0 140 10.0 • ICK 103-2M 10.30 3.77 2.430 1.20 30.0 140 10.0 • ICK 104-2M 10.40 3.77 2.430 1.20 30.0 140 10.0 • ICK 105-2M 10.50 3.77 2.430 1.20 30.0 140 10.0 • ICK 106-2M 10.60 3.77 2.430 1.20 30.0 140 10.0 • • ICK 107-2M 10.70 3.77 2.430 1.20 30.0 140 10.0 • ICK 108-2M 10.80 3.77 2.430 1.20 30.0 140 10.0 • ICK 109-2M 10.90 3.77 2.430 1.20 30.0 140 10.0 • ICK 110-2M 11.00 3.94 2.660 1.32 30.0 140 11.0 • ICK 111-2M 11.10 3.94 2.660 1.32 30.0 140 11.0 • ICK 112-2M 11.20 3.94 2.660 1.32 30.0 140 11.0 • ICK 113-2M 11.30 3.94 2.660 1.32 30.0 140 11.0 • ICK 114-2M 11.40 3.94 2.660 1.32 30.0 140 11.0 • • Can provide high surface finish of up to 1.6 Ra hole cylindricity and straightness of up to 0.05 mm • For cutting conditions see page 68-81 (1) Seat size code For tools, see pages: DCN A-1.5D (4) • DCN R-1.5D (5) • DCN A-3D (6) • DCN R-3D (7) • DCN A-5D (8) • DCN R-5D (9) • DCN A-8D (10) • DCN R-8D (11) • DCN R-10D (11) • DCN R-12D (12) • DCN C-3D (13) • DCN C-5D (13) • DCN C-12D (14) • DCNS-3D (15) • DCNS-5D (16) • DCNM (17) • DCNT (M8-M24) (136) • MNSNT (293) 32 ISCAR

Каталог Iscar монолитные фрезы 2022

Каталог Iscar монолитные фрезы 2022 Каталог Iscar токарный инструмент

Каталог Iscar токарный инструмент Каталог Iscar инструмент для мелкоразмерной обработки

Каталог Iscar инструмент для мелкоразмерной обработки Каталог Iscar токарный инструмент для нарезания канавок

Каталог Iscar токарный инструмент для нарезания канавок Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar дисковые фрезы и фрезерные пластины 2022

Каталог Iscar дисковые фрезы и фрезерные пластины 2022