Каталог Iscar сверла ружейные и для глубокого сверления 2022 - страница 92

Навигация

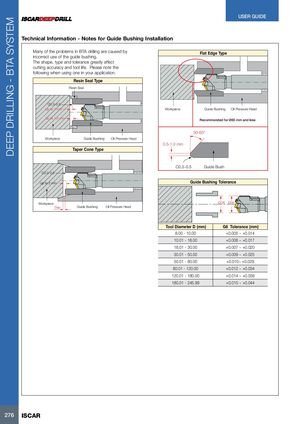

DEEP DRILLING - BTA SYSTEM USER GUIDE Technical Information - Notes for Guide Bushing Installation Many of the problems in BTA drilling are caused by Flat Edge Type incorrect use of the guide bushing. The shape, type and tolerance greatly affect cutting accuracy and tool life. Please note the following when using one in your application. Resin Seal Type Resin Seal C0.3 ˜ 0.5 Up to 1 mm Workpiece Guide Bushing Oil Pressure Head Up to 1.5 mm Recommended for Ø65 mm and less 30˜ 60° Workpiece Guide Bushing Oil Pressure Head 0.5˜ 1.0 mm Taper Cone Type C0.3 ˜ 0.5 Guide Bush C0.3 ˜ 0.5 Up to 2 mm Guide Bushing Tolerance Workpiece DG6 Dh6 Gap Guide Bushing Oil Pressure Head Tool Diameter D (mm) G6 Tolerance (mm) 8.00 - 10.00 +0.005 ~ +0.014 10.01 - 18.00 +0.006 ~ +0.017 18.01 - 30.00 +0.007 ~ +0.020 30.01 - 50.00 +0.009 ~ +0.025 50.01 - 80.00 +0.010~ +0.029 80.01 - 120.00 +0.012 ~ +0.034 120.01 - 180.00 +0.014 ~ +0.039 180.01 - 245.99 +0.015 ~ +0.044 276 ISCAR

Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar инструмент для нарезания резьбы

Каталог Iscar инструмент для нарезания резьбы Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master