Каталог Iscar сверла ружейные и для глубокого сверления 2022 - страница 86

Навигация

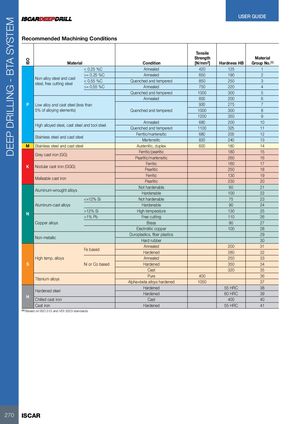

DEEP DRILLING - BTA SYSTEM ISO USER GUIDE Recommended Machining Conditions Tensile Strength Material Material Condition [N/mm2] Hardness HB Group No.(1) < 0.25 %C Annealed 420 125 1 >= 0.25 %C Annealed 650 190 2 Non-alloy steel and caststeel, free cutting steel< 0.55 %CQuenched and tempered 850 250 3 >= 0.55 %C Annealed 750 220 4 Quenched and tempered 1000 300 5 Annealed 600 200 6 P Low alloy and cast steel (less than 930 275 7 5% of alloying elements) Quenched and tempered 1000 300 8 1200 350 9 High alloyed steel, cast steel and tool steel AnnealedQuenched and tempered 680 2001100325 1011 Stainless steel and cast steel Ferritic/martensitic 680 200 12Martensitic82024013 M Stainless steel and cast steel Austenitic, duplex 600 180 14 Grey cast iron (GG) Ferritic/pearlitic 180 15Pearlitic/martensitic26016 K Nodular cast iron (GGG) FerriticPearlitic 160 1725018 Ferritic 130 19 Malleable cast iron Pearlitic 230 20 Aluminum-wrought alloys Not hardenable 60 21 Hardenable 100 22 <=12% Si Not hardenable 75 23 Aluminum-cast alloys Hardenable 90 24 N >12% Si High temperature>1% PbFree cutting 130 2511026 Copper alloys Brass 90 27 Electrolitic copper 100 28 Non-metallic Duroplastics, fiber plastics 29 Hard rubber 30 Fe based AnnealedHardened 200 3128032 High temp. alloys Annealed 250 33 S Ni or Co based Hardened 350 34 Cast 320 35 Titanium alloys Pure 400 36Alpha+beta alloys hardened105037 Hardened steelHChilled cast iron Hardened 55 HRC 38Hardened60 HRC39Cast40040 Cast iron Hardened 55 HRC 41 (1) Based on ISO 513 and VDI 3323 standards 270 ISCAR

Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar инструмент для нарезания резьбы

Каталог Iscar инструмент для нарезания резьбы Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master