Каталог Iscar сверла ружейные и для глубокого сверления 2022 - страница 45

Навигация

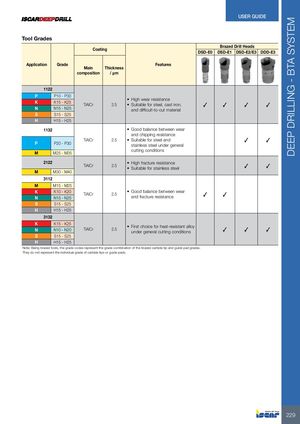

DEEP DRILLING - BTA SYSTEM USER GUIDE Tool Grades Brazed Drill Heads Coating DSD-E0 DSD-E1 DSD-E2/E3 DDD-E3 Application Grade Features Main Thickness composition / µm 1122 P P10 - P30 K K15 - K25 TiAlCr • High wear resistance2.5•Suitable for steel, cast iron,33 3 3 N N15 - N25 and difficult-to-cut material S S15 - S25 H H15 - H25 1132 • Good balance between wear and chipping resistance TiAlCr 2.5 • Suitable for steel andPP20 - P30stainless steel under general 3 3 M M25 - M35 cutting conditions 2122 TiAlCr 2.5 • High fracture resistance•Suitable for stainless steel 3 3 M M30 - M40 3112 M M15 - M25 K K10 - K20 TiAlCrNN15 - N252.5 • Good balance between wearand fracture resistance3 3 S S15 - S25 H H15 - H25 3132 K K15 - K25NN10 - N20TiAlCr 2.5 • First choice for heat-resistant alloyunder general cutting conditions33 3 S S15 - S25 H H15 - H25 Note: Being brazed tools, the grade codes represent the grade combination of the brazed carbide tip and guide pad grades. They do not represent the individual grade of carbide tips or guide pads. 229

Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar инструмент для нарезания резьбы

Каталог Iscar инструмент для нарезания резьбы Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master