Каталог Iscar сверла ружейные и для глубокого сверления 2022 - страница 23

Навигация

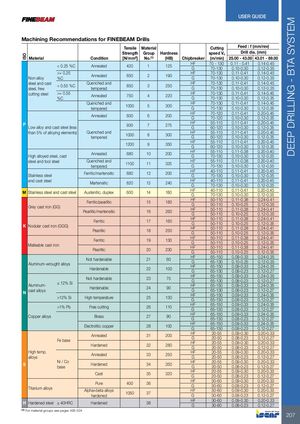

ISO DEEP DRILLING - BTA SYSTEM USER GUIDE Machining Recommendations for FINEBEAM Drills Tensile Material Cutting Feed : f (mm/rev) Strength Group Hardness speed Vc Drill dia. (mm) Material Condition [N/mm2] No.(1) (HB) Chipbreaker (m/min) 25.00 - 43.00 43.01 - 89.00 < 0.25 %C Annealed 420 1 125 HF 70 - 130 0.11 - 0.41 0.14-0.45G70-1300.10-0.300.12-0.35 >= 0.25Non-alloy%C Annealed 650 2 190 HF 70-130 0.11-0.41 0.14-0.45G70-1300.10-0.300.12-0.35 steel and caststeel, free< 0.55 %C Quenched andtempered 850 3 250 HF 70-130 0.11-0.41 0.14-0.45G70-1300.10-0.300.12-0.35 cutting steel >= 0.55%C Annealed 750 4 220 HF 70-130 0.11-0.41 0.14-0.45G70-1300.10-0.300.12-0.35 Quenched andtempered 1000 5 300 HF 70-130 0.11-0.41 0.14-0.45G70-1300.10-0.300.12-0.35 Annealed 600 6 200 HF 70-120 0.11-0.41 0.20-0.45G70-1200.10-0.300.12-0.35 P Low alloy and cast steel (less 930 7 275 HF 55-110 0.11-0.41 0.20-0.45G60-1200.10-0.300.12-0.35 than 5% of alloying elements) Quenched andtempered 1000 8 300 HF 55-110 0.11-0.41 0.20-0.45G60-1200.10-0.300.12-0.35 1200 9 350 HF 55-110 0.11-0.41 0.20-0.45G60-1200.10-0.300.12-0.35 High alloyed steel, cast Annealed 680 10 200 HF 55-110 0.11-0.38 0.20-0.40G70-1300.10-0.300.12-0.35 steel and tool steel Quenched and tempered High tem1p.1a0ll0oys 11 325 HF 55-110 0.11-0.38 0.20-0.40G70-1300.10-0.300.12-0.35 Stainless steel Ferritic/martensitic 680 12 200 HF 40-110 0.11-0.41 0.20-0.45G70-1300.10-0.300.12-0.35 and cast steel Martensitic 820 13 240 HF 40-110 0.11-0.41 0.20-0.45G70-1300.10-0.300.12-0.35 M Stainless steel and cast steel Austenitic, duplex 600 14 180 HF 40-110 0.11-0.41 0.20-0.45G70-1300.10-0.300.12-0.35 Ferritic/pearliticGrey cast iron (GG)Pearlitic/martensitic15180 HF 50-110 0.11-0.38 0.24-0.41G50-1100.10-0.250.12-0.3516260HF50-1100.11-0.380.24-0.41G50-1100.10-0.250.12-0.35 FerriticKNodular cast iron (GGG)Pearlitic 17 160 HF 50-110 0.11-0.38 0.24-0.41G50-1100.10-0.250.12-0.3518250HF50-1100.11-0.380.24-0.41G50-1100.10-0.250.12-0.35 FerriticMalleable cast ironPearlitic 19 130 HF 50-110 0.11-0.38 0.24-0.41G50-1100.10-0.250.12-0.3520230HF50-1100.11-0.380.24-0.41G50-1100.10-0.250.12-0.35 Not hardenableAluminum-wrought alloysHardenable21 60 HF 65-150 0.09-0.33 0.24-0.35G65-1300.10-0.250.12-0.3522100HF65-1500.09-0.330.24-0.35G65-1300.08-0.230.12-0.27 Not hardenableAluminum-≤ 12% SiNcast alloysHardenable>12% SiHigh temperature2375HF65-150 0.09-0.33 0.24-0.35G65-1300.08-0.230.12-0.272490HF65-1500.09-0.330.24-0.35G65-1300.08-0.230.12-0.2725130HF65-1500.09-0.330.24-0.35G65-1300.08-0.230.12-0.27 >1% Pb Free cutting 26 110 HF 65-150 0.09-0.33 0.24-0.35G65-1300.08-0.230.12-0.27 Copper alloys Brass 27 90 HF 65-150 0.09-0.33 0.24-0.35G65-1300.08-0.230.12-0.27 Electrolitic copper 28 100 HF 65-150 0.09-0.33 0.24-0.35G65-1300.08-0.230.12-0.27 AnnealedFe baseHardened 31 200 HF 20-55 0.09-0.30 0.20-0.33G20-500.08-0.230.12-0.2732280HF20-550.09-0.300.20-0.33G20-500.08-0.230.12-0.27 High temp.alloys Annealed 33 250 HF 20-55 0.09-0.30 0.20-0.33G20-500.08-0.230.12-0.27 S Ni / Cobase Hardened 34 350 HF 20-55 0.09-0.30 0.20-0.33G20-500.08-0.230.12-0.27 Cast 35 320 HF 20-55 0.09-0.30 0.20-0.33G20-500.08-0.230.12-0.27 Pure 400 36Titanium alloysAlpha+beta alloyshardened105037HF30-600.09-0.300.20-0.33G30-600.08-0.230.12-0.27HF30-600.09-0.300.20-0.33G30-600.08-0.230.12-0.27 H Hardened steel ≥ 40HRC Hardened 38 HF 30-60 0.09-0.30 0.20-0.33G30-600.08-0.230.12-0.27 (1) For material groups see pages 495-524 207

Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar инструмент для нарезания резьбы

Каталог Iscar инструмент для нарезания резьбы Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master