Каталог Iscar сверла ружейные и для глубокого сверления 2022 - страница 12

Навигация

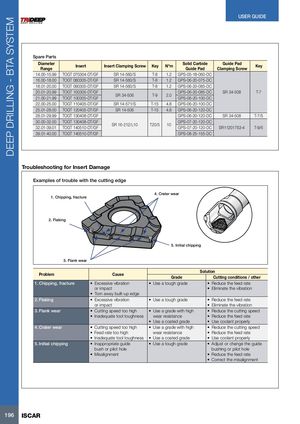

DEEP DRILLING - BTA SYSTEM USER GUIDE Spare Parts DiameterRange Insert Insert Clamping Screw Key N*m Solid CarbideGuide PadGuide PadClamping ScrewKey 14.00-15.99 TOGT 070304-DT/GF SR 14-560/S T-8 1.2 GPS-05-18-060-DC 16.00-18.00 TOGT 080305-DT/GF SR 14-560/S T-8 1.2 GPS-06-20-075-DC 18.01-20.00 TOGT 090305-DT/GF SR 14-560/S T-8 1.2 GPS-06-20-085-DC 20.01-20.99 TOGT 100305-DT/GF21.00-21.99TOGT 100305-DT/GFSR 34-506T-92.0 GPS-06-20-085-DCGPS-06-20-100-DCSR 34-508 T-7 22.00-25.00 TOGT 110405-DT/GF SR 14-571/S T-15 4.8 GPS-06-20-100-DC 25.01-28.00 TOGT 120405-DT/GF SR 14-506 T-15 4.8 GPS-06-20-120-DC 28.01-29.99 TOGT 130408-DT/GF GPS-06-20-120-DC SR 34-508 T-7/5 30.00-32.00 TOGT 130408-DT/GF32.01-39.01TOGT 140510-DT/GFSR 16-212/L10T20/510GPS-07-20-120-DCGPS-07-20-120-DCSR11201753-4T-9/5 39.01-40.00 TOGT 140510-DT/GF GPS-08-25-155-DC Troubleshooting for Insert Damage Examples of trouble with the cutting edge 4. Crater wear 1. Chipping, fracture 2. Flaking 5. Initial chipping 3. Flank wear Solution Problem Cause Grade Cutting conditions / other 1. Chipping, fracture • Excessive vibration • Use a tough grade • Reduce the feed rate or impact • Eliminate the vibration • Torn away built-up edge 2. Flaking • Excessive vibration • Use a tough grade • Reduce the feed rate or impact • Eliminate the vibration 3. Flank wear • Cutting speed too high • Use a grade with high • Reduce the cutting speed • Inadequate tool toughness wear resistance • Reduce the feed rate • Use a coated grade • Use coolant properly 4. Crater wear • Cutting speed too high • Use a grade with high • Reduce the cutting speed • Feed rate too high wear resistance • Reduce the feed rate • Inadequate tool toughness • Use a coated grade • Use coolant properly 5. Initial chipping • Inappropriate guide • Use a tough grade • Adjust or change the guide bush or pilot hole bushing or pilot hole • Misalignment • Reduce the feed rate • Correct the misalignment 196 ISCAR

Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar инструмент для нарезания резьбы

Каталог Iscar инструмент для нарезания резьбы Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master