Каталог Iscar сверла ружейные и для глубокого сверления 2022 - страница 113

Навигация

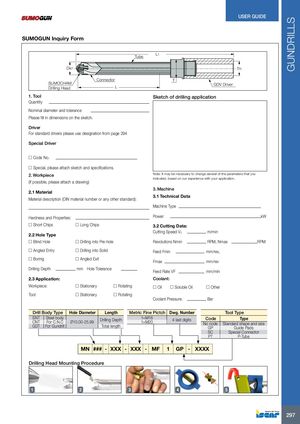

GUNDRILLS USER GUIDE SUMOGUN Inquiry Form Tube L1 Dk7 Th Connector T SUMOCHAMDrilling Head L GDV Driver 1. Tool Sketch of drilling application Quantity Nominal diameter and tolerance Please fill in dimensions on the sketch. Driver For standard drivers please use designation from page 294 Special Driver o Code No. o Special, please attach sketch and specifications. 2. Workpiece Note: It may be necessary to change several of the parameters that you indicated, based on our experience with your application. (If possible, please attach a drawing) 2.1 Material 3. Machine 3.1 Technical Data Material description (DIN material number or any other standard): Machine Type Hardness and Properties: Power: kW o Short Chips o Long Chips 3.2 Cutting Data: 2.2 Hole Type Cutting Speed Vc m/min o Blind Hole o Drilling into Pre-hole Revolutions Nmin RPM, Nmax RPM o Angled Entry o Drilling into Solid Feed Fmin mm/rev, o Boring o Angled Exit Fmax mm/rev Drilling Depth mm Hole Tolerance Feed Rate VF mm/min 2.3 Application: Coolant: Workpiece: o Stationary o Rotating o Oil o Soluble Oil o Other Tool: o Stationary o Rotating Coolant Pressure: Bar Drill Body Type Hole Diameter Length Metric Fine Pictch Dwg. Number Tool Type SNTCNT Steel bodyFor C.N.CØ10.00-25.99 Drilling DepthGDTFor GundrillTotal length1=M161=M204 last digitsCode TypeNo codeStandard shape and sizeGPGuide Pads SC Special Connector PT P-Tube MN ### - XXX - XXX - MF 1 GP - XXXX Drilling Head Mounting Procedure 1 2 3 4 5 297

Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar инструмент для нарезания резьбы

Каталог Iscar инструмент для нарезания резьбы Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master