Каталог Iscar сверла ружейные и для глубокого сверления 2022 - страница 110

Навигация

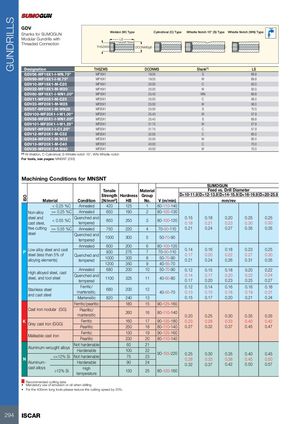

GUNDRILLS ISO GDV Shanks for SUMOGUN Weldon (W) Type Cylindrical (C) Type Whistle Notch 15° (S) Type Whistle Notch (WN) Type Modular Gundrills with LS Threaded Connection THSZWS DCONMSg6 Designation THSZWS DCONMS Shank(1) LS GDV56-MF16X1-I-WN.75" MF16X1 19.05 S 69.8 GDV99-MF16X1-I-W.75" MF16X1 19.05 W 69.8 GDV10-MF16X1-M-C20 MF16X1 20.00 C 50.0 GDV22-MF16X1-M-W20 MF16X1 20.00 W 50.0 GDV80-MF16X1-I-WN1.00" MF16X1 25.40 WN 69.8 GDV11-MF20X1-M-C25 MF20X1 25.00 C 56.0 GDV23-MF20X1-M-W25 MF20X1 25.00 W 56.0 GDV57-MF20X1-M-WN25 MF20X1 25.00 S 70.0 GDV100-MF20X1-I-W1.00" MF20X1 25.40 W 57.9 GDV58-MF20X1-I-WN1.00" MF20X1 25.40 S 69.8 GDV101-MF20X1-I-W1.25" MF20X1 31.75 W 57.9 GDV97-MF20X1-I-C1.25" MF20X1 31.75 C 57.9 GDV12-MF20X1-M-C32 MF20X1 32.00 C 60.0 GDV24-MF20X1-M-W32 MF20X1 32.00 W 60.0 GDV13-MF20X1-M-C40 MF20X1 40.00 C 70.0 GDV25-MF20X1-M-W40 MF20X1 40.00 W 70.0 (1) W-Weldon, C-Cylindrical, S-Whistle notch 15°, WN-Whistle notch For tools, see pages: MNSNT (293) Machining Conditions for MNSNT SUMOGUN Tensile Material Feed vs. Drill Diameter Strength Hardness Group D=10-11.9 D=12-13.9 D=14-15.9 D=16-19.9 D=20-25.9 Material Condition [N/mm2] HB No. V (m/min) mm/rev < 0.25 %C Annealed 420 125 1 80-110-140 Non-alloy >= 0.25 %C Annealed 650 190 2 80-105-130 steel andcast steel,< 0.55 %CQuenched andtempered 850 250 3 80-100-120 0.150.18 0.180.21 0.200.23 0.250.30 0.250.30 free cutting >= 0.55 %C Annealed 750 220 4 70-90-110 0.21 0.24 0.27 0.35 0.35 steel Quenched andtempered 1000 300 5 50-70-90 Annealed 600 200 6 80-100-120 P Low alloy steel and caststeel (less than 5% ofalloying elements)Quenched andtempered9301000275300770-90-1100.14 0.16 0.18 0.23 0.25850-70-900.170.210.200.240.220.260.270.310.300.35 1200 350 9 40-55-70 High alloyed steel, caststeel, and tool steelAnnealed680Quenched andtempered11002003251050-70-90 0.12 0.150.140.171140-60-800.170.200.180.20 0.220.200.220.240.230.250.27 Stainless steeland cast steel Ferritic/martensitic.680 200 12 0.12 0.1440-55-700.130.150.16 0.16 0.180.180.190.21Martensitic820240130.150.170.200.210.24 Ferritic/pearlitic 180 15 90-125-160 Cast iron nodular (GG) Pearlitic/martensitic 260 16 80-110-140 0.20 0.25 0.30 0.35 0.35 K Grey cast iron (GGG) FerriticPearlitic 160 17 90-135-180 0.23 0.28 0.33 0.40 0.422501880-110-1400.270.320.370.450.47 Ferritic 130 19 90-125-160 Malleable cast iron Pearlitic 230 20 80-110-140 Aluminum-wrought alloys Not hardenableHardenable 60 2110022 N <=12% Si Not hardenable 75 23 90-155-220 0.250.28 0.300.33 0.350.38 0.400.45 0.450.50 Aluminum- Hardenable 90 24 0.32 0.37 0.42 0.50 0.57 cast alloys >12% Si Hightemperature 130 25 80-120-160 Recommended cutting data • Mandatory use of emulsion or oil when drilling • For the 400mm long tools please reduce the cutting speed by 20%. 294 ISCAR

Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar инструмент для нарезания резьбы

Каталог Iscar инструмент для нарезания резьбы Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master