Каталог Iscar отрезка 2022 - страница 83

Навигация

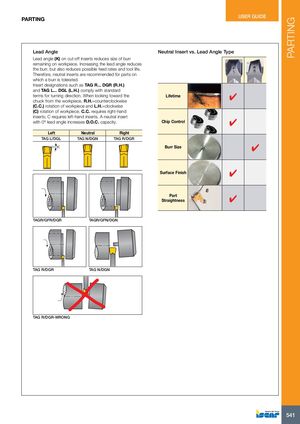

PARTING PARTING USER GUIDE Lead Angle Neutral Insert vs. Lead Angle Type Lead angle (K) on cut-off inserts reduces size of burr remaining on workpiece. Increasing the lead angle reduces the burr, but also reduces possible feed rates and tool life. Therefore, neutral inserts are recommended for parts on which a burr is tolerated. Insert designations such as TAG R... DGR (R.H.) and TAG L... DGL (L.H.) comply with standard terms for turning direction. When looking toward the Lifetime 4 chuck from the workpiece, R.H.=counterclockwise (C.C.) rotation of workpiece and L.H.=clockwise (C) rotation of workpiece. C.C. requires right-hand inserts; C requires left-hand inserts. A neutral insert with 0º lead angle increases D.O.C. capacity. Chip Control 4 Left Neutral Right TAG L/DGL TAG N/DGN TAG R/DGR K Burr Size 4 Surface Finish 4 PartStraightness 4 TAGR/GFR/DGR TAGR/GFN/DGN TAG R/DGR TAG N/DGN TAG R/DGR-WRONG 541

Каталог Iscar монолитные фрезы 2022

Каталог Iscar монолитные фрезы 2022 Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar расточные системы

Каталог Iscar расточные системы Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022