Каталог Iscar отрезка 2022 - страница 72

Навигация

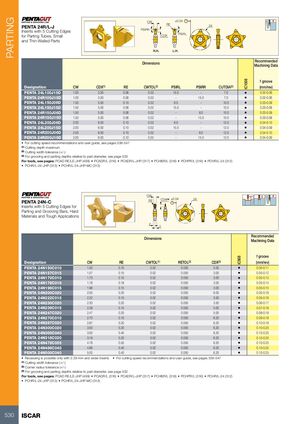

PARTING IC908 IC1008 CW ±0.04 PENTA 24R/L-J RE 24 Inserts with 5 Cutting Edges PSIRR for Parting Tubes, Small CDX PSIRL and Thin-Walled Parts R.H. L.H. Dimensions RecommendedMachining Data f groove Designation CW CDX(1) RE CWTOL(2) PSIRL PSIRR CUTDIA(3) (mm/rev) PENTA 24L100J15D 1.00 3.50 0.06 0.02 15.0 - 7.0 • 0.02-0.06 PENTA 24R100J15D 1.00 3.50 0.06 0.02 - 15.0 7.0 • 0.02-0.06 PENTA 24L150J06D 1.50 5.00 0.10 0.02 6.0 - 10.0 • 0.03-0.09 PENTA 24L150J15D 1.50 5.00 0.06 0.02 15.0 - 10.0 • 0.03-0.08 PENTA 24R150J06D 1.50 5.00 0.06 0.02 - 6.0 10.0 • 0.03-0.09 PENTA 24R150J15D 1.50 5.00 0.06 0.02 - 15.0 10.0 • 0.03-0.08 PENTA 24L200J06D 2.00 6.00 0.10 0.02 6.0 - 12.0 • 0.04-0.10 PENTA 24L200J15D 2.00 6.00 0.10 0.02 15.0 - 12.0 • 0.04-0.09 PENTA 24R200J06D 2.00 6.00 0.10 0.02 - 6.0 12.0 • 0.04-0.10 PENTA 24R200J15D 2.00 6.00 0.10 0.02 - 15.0 12.0 • 0.04-0.09 • For cutting speed recommendations and user guide, see pages 538-547 (1) Cutting depth maximum (2) Cutting width tolerance (+/-) (3) For grooving and parting depths relative to part diameter, see page 533 For tools, see pages: PCAD RE/LE-JHP (499) • PCADR/L (316) • PCADR/L-JHP (317) • PCHBR/L (318) • PCHPR/L (316) • PCHR/L-24 (312) • PCHR/L-24-JHP (313) • PCHR/L-24-JHP-MC (313) CW PENTA 24N-C RE CDX(3) ±0.04 24 Inserts with 5 Cutting Edges for Parting and Grooving Bars, Hard Materials and Tough Applications 2 2 Dimensions RecommendedMachining Data f groove Designation CW RE CWTOL(1) RETOL(2) CDX(3) (mm/rev) PENTA 24N150C010 1.50 0.10 0.02 0.050 5.00 • 0.05-0.11 PENTA 24N157C015 1.57 0.15 0.02 0.050 3.00 • 0.05-0.12 PENTA 24N170C010 1.70 0.10 0.02 0.050 3.00 • 0.05-0.13 PENTA 24N178C018 1.78 0.18 0.02 0.050 3.00 • 0.05-0.14 PENTA 24N196C015 1.96 0.15 0.02 0.050 3.00 • 0.05-0.15 PENTA 24N200C020 2.00 0.20 0.02 0.050 6.00 • 0.05-0.16 PENTA 24N222C015 2.22 0.15 0.02 0.050 3.50 • 0.05-0.16 PENTA 24N230C020 2.30 0.20 0.02 0.050 3.50 • 0.06-0.17 PENTA 24N239C015 2.39 0.15 0.02 0.050 5.00 • 0.07-0.18 PENTA 24N247C020 2.47 0.20 0.02 0.050 5.00 • 0.08-0.18 PENTA 24N270C010 2.70 0.10 0.02 0.050 6.20 • 0.09-0.18 PENTA 24N287C020 2.87 0.20 0.02 0.050 6.20 • 0.10-0.18 PENTA 24N300C020 3.00 0.20 0.02 0.050 6.20 • 0.10-0.20 PENTA 24N300C040 3.00 0.40 0.02 0.050 6.20 • 0.10-0.20 PENTA 24N318C020 3.18 0.20 0.02 0.050 6.20 • 0.10-0.20 PENTA 24N478C055 4.78 0.55 0.02 0.050 6.20 • 0.10-0.25 PENTA 24N486C040 4.86 0.40 0.02 0.050 6.20 • 0.10-0.25 PENTA 24N500C040 5.00 0.40 0.02 0.050 6.20 • 0.10-0.25 • Recessing is possible only with 2.39 mm and wider inserts • For cutting speed recommendations and user guide, see pages 538-547 (1) Cutting width tolerance (+/-) (2) Corner radius tolerance (+/-) (3) For grooving and parting depths relative to part diameter, see page 532 For tools, see pages: PCAD RE/LE-JHP (499) • PCADR/L (316) • PCADR/L-JHP (317) • PCHBR/L (318) • PCHPR/L (316) • PCHR/L-24 (312) • PCHR/L-24-JHP (313) • PCHR/L-24-JHP-MC (313) 530 ISCAR

Каталог Iscar монолитные фрезы 2022

Каталог Iscar монолитные фрезы 2022 Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar расточные системы

Каталог Iscar расточные системы Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022