Каталог Iscar отрезка 2022 - страница 60

Навигация

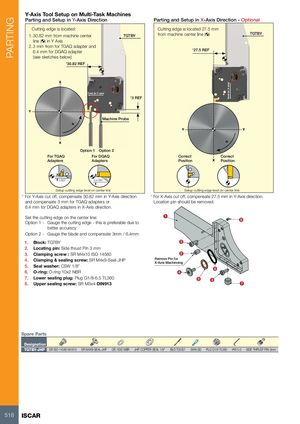

PARTING Feed (in X axis) Y-Axis Tool Setup on Multi-Task Machines Parting and Setup in Y-Axis Direction Parting and Setup in X-Axis Direction - Optional Cutting edge is located: Cutting edge is located 27.5 mm 1. 30.82 mm from machine center TGTBY from machine center line ( ) TGTBY line ( ) in Y Axis 2. 3 mm from for TGAQ adapter and 6.4 mm for DGAQ adapter *27.5 REF (see sketches below) *30.82 REF X Feed (in Y axis) *3 REF Y Machine Probe n Y Y X n Option 1 Option 2 For TGAQ For DGAQ Correct Correct Adapters Adapters Position X Position 3 REF 6.4 REF Setup cutting edge level on center line Setup cutting edge level on center line * For Y-Axis cut off, compensate 30.82 mm in Y-Axis direction * For X-Axis cut off, compensate 27.5 mm in Y-Axis direction. and compensate 3 mm for TGAQ adapters or Location pin should be removed. 6.4 mm for DGAQ adapters in X-Axis direction. Set the cutting edge on the center line: 1 8 Option 1 - Gauge the cutting edge - this is preferable due to better accuracy Option 2 - Gauge the blade and compensate 3mm / 6.4mm 1. Block: TGTBY 3 2. Locating pin: Side thrust Pin 3 mm 3. Clamping screw : SR M4x10 ISO 14580 2 4. Clamping & sealing screw: SR M4x9-Seal-JHP Remove Pin forX-Axis Machinning 5. Seal washer: CSW 1/8’’ 6 6. O-ring: O-ring 10x2 NBR 4 7. Lower sealing plug: Plug G1/8-6.5 TL360 5 3 8. Upper sealing screw: SR M3x4-DIN913 7 Spare Parts Designation TGTBY-JHP SR ISO 14580 M4X10 SR M4X9-SEAL-JHP OR 16X2 NBR JHP COPPER SEAL 1/8" BLD T20/S7 SW6-SD PLG G1/8 TL360 HW 5.0 SIDE THRUST PIN 3mm 518 ISCAR

Каталог Iscar монолитные фрезы 2022

Каталог Iscar монолитные фрезы 2022 Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar расточные системы

Каталог Iscar расточные системы Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022