Каталог Iscar отрезка 2022 - страница 48

Навигация

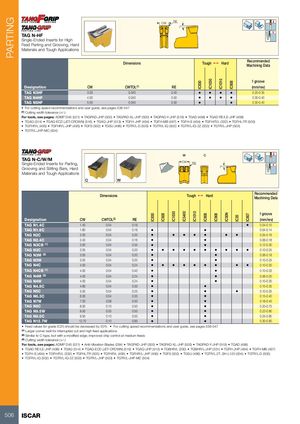

PARTING IC830 IC928 IC1030 IC5400 IC1010 IC830 IC808 IC1030 IC908 IC1010 IC30N IC808 IC20 IC807 CW RE 7° TAG N-HF Single-Ended Inserts for High Feed Parting and Grooving, Hard Materials and Tough Applications Dimensions Tough 1 Hard RecommendedMachining Data f groove Designation CW CWTOL(1) RE (mm/rev) TAG N3HF 3.00 0.040 0.40 • • • • 0.25-0.35 TAG N4HF 4.00 0.040 0.50 • • • • 0.30-0.40 TAG N5HF 5.00 0.040 0.50 • • 0.30-0.40 • For cutting speed recommendations and user guide, see pages 538-547 (1) Cutting width tolerance (+/-) For tools, see pages: ADMP D45 (521) • TAGPAD-JHP (500) • TAGPAD-XL-JHP (500) • TAGPAD-Y-JHP (519) • TGAD (498) • TGAD RE/LE-JHP (498) • TGAQ (514) • TGAQ-ECD (JET-CROWN) (516) • TGAQ-JHP (513) • TGFH-JHP (494) • TGFH-MB (497) • TGFH-S (494) • TGFH/R/L (332) • TGFHL-TR (505) • TGFHR/L (495) • TGFHR/L-JHP (495) • TGFS (502) • TGSU (496) • TGTR/L-D (505) • TGTR/L-IQ (502) • TGTR/L-IQ-2Z (503) • TGTR/L-JHP (503) • TGTR/L-JHP-MC (504) W C TAG N-C/W/M Single-Ended Inserts for Parting, CW RE Grooving and Slitting Bars, Hard 7º Materials and Tough Applications Dimensions Tough 1 Hard RecommendedMachining Data f groove Designation CW CWTOL(3) RE (mm/rev) TAG N1.4C 1.40 0.04 0.16 • 0.04-0.10 TAG N1.6C 1.60 0.04 0.16 • • 0.04-0.14 TAG N2C 2.00 0.04 0.20 • • • • • • • 0.05-0.16 TAG N2.4C 2.40 0.04 0.16 • • 0.06-0.18 TAG N3CB (1) 3.00 0.04 0.35 • • 0.12-0.30 TAG N3C 3.05 0.04 0.20 • • • • • • • • • • 0.10-0.25 TAG N3M (2) 3.05 0.04 0.20 • • 0.06-0.18 TAG N3W 3.05 0.04 0.20 • • 0.10-0.25 TAG N4C 4.00 0.04 0.24 • • • • • • • • • 0.10-0.30 TAG N4CB (1) 4.00 0.04 0.40 • • 0.10-0.33 TAG N4M (2) 4.00 0.04 0.24 • • 0.06-0.20 TAG N4W 4.00 0.04 0.24 • • 0.10-0.30 TAG N4.8C 4.80 0.04 0.30 • • 0.10-0.35 TAG N5C 5.05 0.04 0.25 • • • 0.10-0.35 TAG N6.3C 6.30 0.04 0.35 • • 0.15-0.40 TAG N7W 7.00 0.08 0.50 • • 0.18-0.40 TAG N8C 8.00 0.10 0.50 • • 0.20-0.70 TAG N9.5W 9.50 0.05 0.50 • • 0.22-0.80 TAG N9.5C 9.50 0.10 0.50 • • 0.25-0.80 TAG N12.7W 12.70 0.10 0.85 • • 0.30-0.80 • Feed values for grade IC20 should be decreased by 50% • For cutting speed recommendations and user guide, see pages 538-547 (1) Larger corner radii for interrupted cut and high feed applications (2) Similar to C-type, but with a modified edge; improved chip control at medium feeds (3) Cutting width tolerance (+/-) For tools, see pages: ADMP D45 (521) • Anti-Vibration Blades (284) • TAGPAD-JHP (500) • TAGPAD-XL-JHP (500) • TAGPAD-Y-JHP (519) • TGAD (498) • TGAD RE/LE-JHP (498) • TGAQ (514) • TGAQ-ECD (JET-CROWN) (516) • TGAQ-JHP (513) • TGBHR/L (330) • TGBHR/L-JHP (331) • TGFH-JHP (494) • TGFH-MB (497) • TGFH-S (494) • TGFH/R/L (332) • TGFHL-TR (505) • TGFHR/L (495) • TGFHR/L-JHP (495) • TGFS (502) • TGSU (496) • TGTR/L-2T..SH-L120 (504) • TGTR/L-D (505) • TGTR/L-IQ (502) • TGTR/L-IQ-2Z (503) • TGTR/L-JHP (503) • TGTR/L-JHP-MC (504) 506 ISCAR

Каталог Iscar монолитные фрезы 2022

Каталог Iscar монолитные фрезы 2022 Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar расточные системы

Каталог Iscar расточные системы Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022