Каталог Iscar отрезка 2022 - страница 32

Навигация

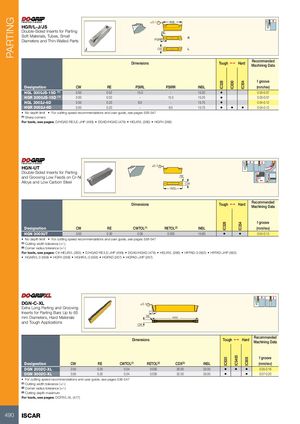

PARTING IC328 IC328IC830 IC830 IC5400 IC354IC354 IC808 ±0.1 lNSL HGR/L-J/JS Double-Sided Inserts for Parting RE Soft Materials, Tubes, SmallDiameters and Thin-Walled Parts PSIRR R CW L Dimensions Tough 1 Hard RecommendedMachining Data f groove Designation CW RE PSIRL PSIRR INSL (mm/rev) HGL 3000JS-15D (1) 3.00 0.02 15.0 - 15.20 • 0.03-0.07 HGR 3000JS-15D (1) 3.00 0.02 - 15.0 15.20 • 0.03-0.07 HGL 3002J-6D 3.00 0.20 6.0 - 15.70 • 0.04-0.12 HGR 3002J-6D 3.00 0.20 - 6.0 15.70 • • • 0.04-0.12 • No depth limit • For cutting speed recommendations and user guide, see pages 538-547 (1) Sharp corners For tools, see pages: D/HGAD RE/LE-JHP (499) • DGAD/HGAD (479) • HELIR/L (266) • HGFH (268) HGN-UT ±0.1 Double-Sided Inserts for Parting and Grooving Low Feeds on Cr-Ni RE Alloys and Low Carbon Steel CW INSL Dimensions Tough 1 Hard RecommendedMachining Data f groove Designation CW RE CWTOL(1) RETOL(2) INSL (mm/rev) HGN 3003UT 3.00 0.30 0.05 0.030 15.80 • • 0.04-0.13 • No depth limit • For cutting speed recommendations and user guide, see pages 538-547 (1) Cutting width tolerance (+/-) (2) Corner radius tolerance (+/-) For tools, see pages: C#-HELIR/L (265) • D/HGAD RE/LE-JHP (499) • DGAD/HGAD (479) • HELIR/L (266) • HFPAD-3 (562) • HFPAD-JHP (562) • HGAIR/L-3 (568) • HGFH (268) • HGHR/L-3 (558) • HGPAD (267) • HGPAD-JHP (267) DGN-C-XL ±0.1 Extra Long Parting and Grooving Inserts for Parting Bars Up to 65 7° mm Diameters, Hard Materials RE INSL and Tough Applications CW Dimensions Tough 1 Hard RecommendedMachining Data f groove Designation CW RE CWTOL(1) RETOL(2) CDX(3) INSL (mm/rev) DGN 2002C-XL 2.05 0.20 0.04 0.030 30.00 32.00 • • • 0.05-0.16 DGN 3002C-XL 3.00 0.20 0.04 0.030 32.50 35.00 • • 0.07-0.20 • For cutting speed recommendations and user guide, see pages 538-547 (1) Cutting width tolerance (+/-) (2) Corner radius tolerance (+/-) (3) Cutting depth maximum For tools, see pages: DGTR/L-XL (477) 490 ISCAR

Каталог Iscar монолитные фрезы 2022

Каталог Iscar монолитные фрезы 2022 Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar расточные системы

Каталог Iscar расточные системы Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022