Каталог Iscar отрезка 2022 - страница 24

Навигация

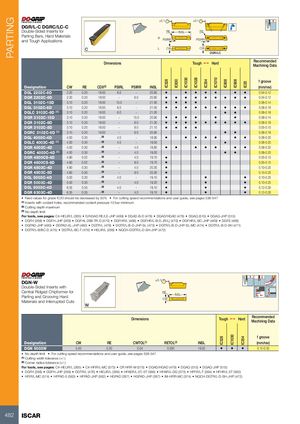

PARTING IC328 IC830 IC1030 IC1028 IC354 IC1010 IC328 IC808 IC1030 IC908 IC20IC354 ±0.1 ±0.1 DGR/L-C DGRC/LC-C Double-Sided Inserts for RE INSL RE Parting Bars, Hard Materialsand Tough Applications R PSIRR PSIRR L CW CW DGR/LC Dimensions Tough 1 Hard RecommendedMachining Data f groove Designation CW RE CDX(2) PSIRL PSIRR INSL (mm/rev) DGL 2202C-6D 2.20 0.20 18.00 6.0 - 20.80 • • • • • • • 0.04-0.12 DGR 2202C-6D 2.20 0.20 18.00 - 6.0 20.80 • • • • • • • • • 0.04-0.12 DGL 3102C-15D 3.10 0.20 18.00 15.0 - 21.00 • • • • 0.08-0.14 DGL 3102C-6D 3.10 0.20 18.00 6.0 - 21.00 • • • • • • • • • 0.08-0.18 DGLC 3102C-6D (1) 3.10 0.20 18.00 6.0 - 21.00 • • 0.08-0.18 DGR 3102C-15D 3.10 0.20 18.00 - 15.0 20.90 • • • • • • 0.08-0.14 DGR 3102C-6D 3.10 0.20 18.00 - 6.0 21.00 • • • • • • • • • 0.08-0.18 DGR 3102C-8D 3.10 0.20 18.00 - 8.0 21.10 • • • • 0.05-0.15 DGRC 3102C-6D (1) 3.10 0.20 18.00 - 6.0 20.90 • • 0.08-0.18 DGL 4003C-4D 4.00 0.30 - (3) 4.0 - 18.90 • • • • • • • 0.08-0.20 DGLC 4003C-4D (1) 4.00 0.30 - (3) 4.0 - 19.00 • 0.08-0.20 DGR 4003C-4D 4.00 0.30 - (3) - 4.0 18.80 • • • • • • • 0.08-0.20 DGRC 4003C-4D (1) 4.00 0.30 - (3) - 4.0 19.00 • • 0.08-0.20 DGR 4800CS-4D 4.80 0.02 - (3) - 4.0 19.70 • 0.05-0.15 DGR 4800CS-8D 4.80 0.02 - (3) - 8.0 19.70 • 0.05-0.15 DGR 4803C-4D 4.80 0.30 - (3) - 4.0 20.30 • 0.10-0.25 DGR 4803C-8D 4.80 0.30 - (3) - 8.0 20.30 • 0.10-0.20 DGL 5003C-4D 5.00 0.30 - (3) 4.0 - 19.10 • • • 0.10-0.25 DGR 5003C-4D 5.00 0.30 - (3) - 4.0 19.20 • • • 0.10-0.25 DGL 6303C-4D 6.35 0.35 - (3) 4.0 - 19.10 • • • 0.12-0.30 DGR 6303C-4D 6.35 0.35 - (3) - 4.0 19.10 • • • 0.12-0.30 • Feed values for grade IC20 should be decreased by 50% • For cutting speed recommendations and user guide, see pages 538-547 (1) Inserts with coolant holes, recommended coolant pressure 10 bar minimum (2) Cutting depth maximum (3) No depth limit For tools, see pages: C#-HELIR/L (265) • D/HGAD RE/LE-JHP (499) • DGAD-B-D (479) • DGAD/HGAD (479) • DGAQ (515) • DGAQ-JHP (515) • DGFH (268) • DGFH-JHP (269) • DGFHL-26B-TR-D (470) • DGFHR/L (468) • DGFHR/L-B-D..(R/L) (470) • DGFHR/L-BC-JHP (469) • DGFS (469) • DGPAD-JHP (480) • DGPAD-XL-JHP (480) • DGTR/L (476) • DGTR/L-B-D-JHP-SL (473) • DGTR/L-B-D-JHP-SL-MC (474) • DGTR/L-B-D-SH (471) • DGTR/L-B/BC-D (475) • DGTR/L-BC-T (476) • HELIR/L (266) • NQCH-DGTR/L-D-SH-JHP (472) DGN-W ±0.1 Double-Sided Inserts with Central Ridged Chipformer for RE Parting and Grooving Hard INSLCW Materials and Interrupted Cuts Dimensions Tough 1 Hard RecommendedMachining Data f groove Designation CW RE CWTOL(1) RETOL(2) INSL (mm/rev) DGN 5003W 5.00 0.30 0.04 0.030 19.00 • • • 0.12-0.33 • No depth limit • For cutting speed recommendations and user guide, see pages 538-547 (1) Cutting width tolerance (+/-) (2) Corner radius tolerance (+/-) For tools, see pages: C#-HELIR/L (265) • C#-HFIR/L-MC (573) • CR HFIR-M (575) • DGAD/HGAD (479) • DGAQ (515) • DGAQ-JHP (515) • DGFH (268) • DGFH-JHP (269) • DGTR/L (476) • HELIR/L (266) • HFAER/L-5T, 6T (566) • HFAIR/L-DG (573) • HFFR/L-T (564) • HFHR/L-5T (560) • HFIR/L-MC (574) • HFPAD-5 (563) • HFPAD-JHP (562) • HGPAD (267) • HGPAD-JHP (267) • IM-HFIR-MC (574) • NQCH-DGTR/L-D-SH-JHP (472) 482 ISCAR

Каталог Iscar монолитные фрезы 2022

Каталог Iscar монолитные фрезы 2022 Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar расточные системы

Каталог Iscar расточные системы Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022