Каталог Iscar отрезка 2022 - страница 11

Навигация

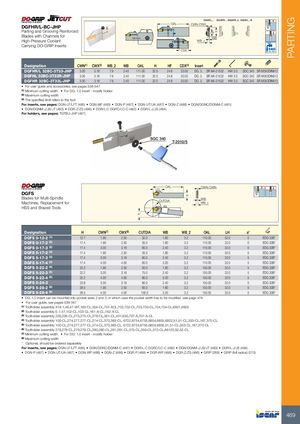

PARTING DGHFL... DGHFR... DGHFR...L DGHFL...R DGFHR/L-BC-JHP OAL CWN-CWX Parting and Grooving Reinforced HF H Blades with Channels for Min Max WB High-Pressure Coolant WB_2 Carrying DO-GRIP Inserts CDX Bar Max Designation CWN(1) CWX(2) WB_2 WB OAL H HF CDX(3) Insert DGFHR/L 32BC-3T33-JHP 3.00 3.18 7.9 2.40 111.00 32.0 24.8 33.00 DG. 3.. SR M4-21532 HW 3.0 SGC 340 SR M3X3DIN913 DGFHL 32BC-3T33R-JHP 3.00 3.18 7.9 2.40 111.00 32.0 24.8 33.00 DG. 3.. SR M4-21532 HW 3.0 SGC 340 SR M3X3DIN913 DGFHR 32BC-3T33L-JHP 3.00 3.18 7.9 2.40 111.00 32.0 24.8 33.00 DG. 3.. SR M4-21532 HW 3.0 SGC 340 SR M3X3DIN913 • For user guide and accessories, see pages 538-547 (1) Minimum cutting width • For DG: 1.0 insert - modify holder (2) Maximum cutting width (3) The specified limit refers to the tool For inserts, see pages: DGN-LF/LFT (485) • DGN-MF (485) • DGN-P (487) • DGN-UT/UA (487) • DGN-Z (486) • DGN/DGNC/DGNM-C (481) • DGN/DGNM-J/JS/JT (483) • DGR-Z/ZS (486) • DGR/L-C DGRC/LC-C (482) • DGR/L-J/JS (484) For holders, see pages: TGTBU-JHP (497) SGC 340 T-2010/5 OALLH CWN-CWN DGFS H Blades for Multi-SpindleMachines, Replacement for CUTDIA WBWB_2 HSS and Brazed Tools a° Designation H CWN(7) CWX(8) CUTDIA WB WB_2 OAL LH a° DGFS 0-12-2 (1) 12.7 1.90 2.50 32.0 1.60 3.2 110.00 32.0 0 EDG 33B* DGFS 0-17-2 (2) 17.4 1.90 2.50 35.0 1.60 3.2 110.00 32.0 0 EDG 33B* DGFS 0-17-3 (2) 17.4 3.00 3.18 60.0 2.40 3.2 110.00 32.0 0 EDG 33B* DGFS 5-17-2 (3) 17.4 1.90 2.50 35.0 1.60 3.2 110.00 32.0 5 EDG 33B* DGFS 5-17-3 (3) 17.4 3.00 3.18 60.0 2.40 3.2 110.00 32.0 5 EDG 33B* DGFS 5-17-4 (3) 17.4 4.00 4.00 60.0 3.20 3.2 110.00 32.0 5 EDG 33B* DGFS 5-22-2 (4) 22.2 1.90 2.50 50.0 1.60 3.2 150.00 32.0 5 EDG 33B* DGFS 5-22-3 (5) 22.2 3.00 3.18 75.0 2.40 3.2 150.00 32.0 5 EDG 33B* DGFS 5-22-4 (5) 22.2 4.00 4.00 80.0 3.20 3.2 150.00 32.0 5 EDG 33B* DGFS 5-24-3 23.8 3.00 3.18 80.0 2.40 3.2 150.00 32.0 5 EDG 33B* DGFS 5-28-2 (6) 28.5 1.90 2.50 65.0 1.60 3.2 150.00 32.0 5 EDG 33B* DGFS 5-28-4 (6) 28.5 4.00 4.00 100.0 3.20 3.2 150.00 32.0 5 EDG 33B* • DG..1.0 insert can be mounted into pocket sizes 2 and 3. in which case the pocket width has to be modified -see page 479 • For user guide, see pages 538-547 (1) Toolholder assembly X18-1,46,47-WT,160-CL,354-CL,701-ACL,702,702-CL,703,703-CL,704,704-CL,6921,6925 (2) Toolholder assembly E-7,47,102-CL,103-CL,161-A-CL,162-A-CL (3) Toolholder assembly 226,226-CL,275,275-CL,276-CL,361-CL,431,630,707-A,707-A-CL (4) Toolholder assembly 100-CL,274,277,277-CL,274-CL,370,383-CL, 6722,6754,6755,6854,6855,6922,51,51-CL,353-CL,167,370-CL (5) Toolholder assembly 100-CL,274,277,277-CL,274-CL,370,383-CL, 6722,6754,6755,6854,6855,51,51-CL,353-CL,167,370-CL (6) Toolholder assembly 278,278-CL,279,279-CL,280,280-CL,281,281-CL,375-CL,359-CL,372-CL,A6120,52,52-CL (7) Minimum cutting width • For DG: 1.0 insert - modify holder (8) Maximum cutting width * Optional, should be ordered separately For inserts, see pages: DGN-LF/LFT (485) • DGN/DGNC/DGNM-C (481) • DGR/L-C DGRC/LC-C (482) • DGN/DGNM-J/JS/JT (483) • DGR/L-J/JS (484) • DGN-P (487) • DGN-UT/UA (487) • DGN-WP (488) • DGN-Z (486) • DGR-P (488) • DGR-WP (488) • DGR-Z/ZS (486) • GRIP (269) • GRIP (full radius) (270) 469

Каталог Iscar монолитные фрезы 2022

Каталог Iscar монолитные фрезы 2022 Каталог Iscar резьбонарезные фрезы

Каталог Iscar резьбонарезные фрезы Каталог Iscar расточные системы

Каталог Iscar расточные системы Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022