Каталог Iscar обработка канавок 2022 - страница 8

Навигация

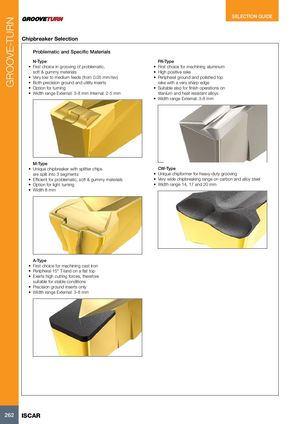

GROOVE-TURN SELECTION GUIDE Chipbreaker Selection Problematic and Specific Materials N-Type PA-Type • First choice in grooving of problematic, • First choice for machining aluminum soft & gummy materials • High positive rake • Very low to medium feeds (from 0.05 mm/rev) • Peripheral ground and polished top • Both precision ground and utility inserts rake with a very sharp edge • Option for turning • Suitable also for finish operations on • Width range External: 3-8 mm Internal: 2-5 mm titanium and heat resistant alloys • Width range External: 3-8 mm M-Type • Unique chipbreaker with splitter chips CW-Type are split into 3 segments • Unique chipformer for heavy-duty grooving • Efficient for problematic, soft & gummy materials • Very wide chipbreaking range on carbon and alloy steel • Option for light turning • Width range 14, 17 and 20 mm • Width 8 mm A-Type • First choice for machining cast Iron • Peripheral 15° T-land on a flat top • Exerts high cutting forces, therefore suitable for stable conditions • Precision ground inserts only • Width range External: 3-8 mm 262 ISCAR

Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar инструментальная оснастка 2022

Каталог Iscar инструментальная оснастка 2022