Каталог Iscar обработка канавок 2022 - страница 66

Навигация

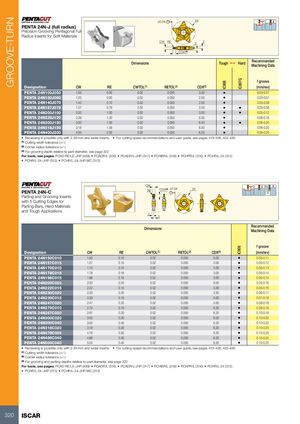

GROOVE-TURN IC908 IC807GIC908 ±0.04 24 PENTA 24N-J (full radius) Precision Grooving Pentagonal Full Radius Inserts for Soft Materials CW RE 2 2 CDX (3) Dimensions Tough 1 Hard RecommendedMachining Data f groove Designation CW RE CWTOL(1) RETOL(2) CDX(3) (mm/rev) PENTA 24N100J050 1.00 0.50 0.02 0.050 3.50 • 0.03-0.07 PENTA 24N120J060 1.20 0.60 0.02 0.050 2.00 • 0.03-0.07 PENTA 24N140J070 1.40 0.70 0.02 0.050 2.00 • 0.05-0.08 PENTA 24N157J079 1.57 0.79 0.02 0.050 3.00 • • 0.05-0.08 PENTA 24N200J100 2.00 1.00 0.02 0.050 3.00 • • 0.05-0.12 PENTA 24N239J120 2.39 1.20 0.02 0.050 5.00 • 0.06-0.16 PENTA 24N300J150 3.00 1.50 0.02 0.050 6.50 • • 0.06-0.20 PENTA 24N318J159 3.18 1.59 0.02 0.050 6.50 • 0.06-0.20 PENTA 24N400J200 4.00 2.00 0.02 0.050 6.25 • 0.06-0.20 • Recessing is possible only with 2.39 mm and wider inserts. • For cutting speed recommendations and user guide, see pages 419-428, 432-436 (1) Cutting width tolerance (+/-) (2) Corner radius tolerance (+/-) (3) For grooving depth relative to part diameter, see page 322 For tools, see pages: PCAD RE/LE-JHP (499) • PCADR/L (316) • PCADR/L-JHP (317) • PCHBR/L (318) • PCHPR/L (316) • PCHR/L-24 (312) • PCHR/L-24-JHP (313) • PCHR/L-24-JHP-MC (313) CW PENTA 24N-C RE CDX(3) ±0.04 24 Parting and Grooving Inserts with 5 Cutting Edges for Parting Bars, Hard Materials and Tough Applications 2 2 Dimensions RecommendedMachining Data f groove Designation CW RE CWTOL(1) RETOL(2) CDX(3) (mm/rev) PENTA 24N150C010 1.50 0.10 0.02 0.050 5.00 • 0.05-0.11 PENTA 24N157C015 1.57 0.15 0.02 0.050 3.00 • 0.05-0.12 PENTA 24N170C010 1.70 0.10 0.02 0.050 3.00 • 0.05-0.13 PENTA 24N178C018 1.78 0.18 0.02 0.050 3.00 • 0.05-0.14 PENTA 24N196C015 1.96 0.15 0.02 0.050 3.00 • 0.05-0.15 PENTA 24N200C020 2.00 0.20 0.02 0.050 6.00 • 0.05-0.16 PENTA 24N222C015 2.22 0.15 0.02 0.050 3.50 • 0.05-0.16 PENTA 24N230C020 2.30 0.20 0.02 0.050 3.50 • 0.06-0.17 PENTA 24N239C015 2.39 0.15 0.02 0.050 5.00 • 0.07-0.18 PENTA 24N247C020 2.47 0.20 0.02 0.050 5.00 • 0.08-0.18 PENTA 24N270C010 2.70 0.10 0.02 0.050 6.20 • 0.09-0.18 PENTA 24N287C020 2.87 0.20 0.02 0.050 6.20 • 0.10-0.18 PENTA 24N300C020 3.00 0.20 0.02 0.050 6.20 • 0.10-0.20 PENTA 24N300C040 3.00 0.40 0.02 0.050 6.20 • 0.10-0.20 PENTA 24N318C020 3.18 0.20 0.02 0.050 6.20 • 0.10-0.20 PENTA 24N478C055 4.78 0.55 0.02 0.050 6.20 • 0.10-0.25 PENTA 24N486C040 4.86 0.40 0.02 0.050 6.20 • 0.10-0.25 PENTA 24N500C040 5.00 0.40 0.02 0.050 6.20 • 0.10-0.25 • Recessing is possible only with 2.39 mm and wider inserts • For cutting speed recommendations and user guide, see pages 419-428, 432-436 (1) Cutting width tolerance (+/-) (2) Corner radius tolerance (+/-) (3) For grooving and parting depths relative to part diameter, see page 322 For tools, see pages: PCAD RE/LE-JHP (499) • PCADR/L (316) • PCADR/L-JHP (317) • PCHBR/L (318) • PCHPR/L (316) • PCHR/L-24 (312) • PCHR/L-24-JHP (313) • PCHR/L-24-JHP-MC (313) 320 ISCAR

Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar инструментальная оснастка 2022

Каталог Iscar инструментальная оснастка 2022