Каталог Iscar обработка канавок 2022 - страница 46

Навигация

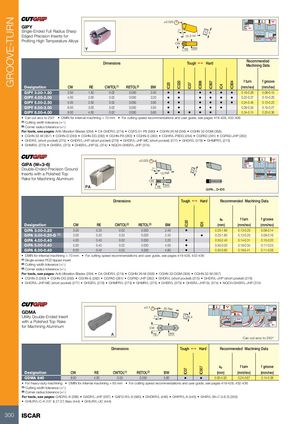

GROOVE-TURN IC20 IC320 IC20IC07 IC07 IC806ID5IC507 IC907 IC4 IC804 ±0.025 GIPY Single-Ended Full Radius Sharp 7° 5 Edged Precision Inserts for 15.3 Ref. Profiling High Temperature Alloys CW RE BW Dimensions Tough 1 Hard RecommendedMachining Data f turn f groove Designation CW RE CWTOL(1) RETOL(2) BW (mm/rev) (mm/rev) GIPY 3.00-1.50 3.00 1.50 0.02 0.050 2.40 • • • • • • 0.19-0.28 0.08-0.15 GIPY 4.00-2.00 4.00 2.00 0.02 0.050 3.20 • • • • • • 0.22-0.37 0.10-0.20 GIPY 5.00-2.50 5.00 2.50 0.02 0.050 3.90 • • • • • • 0.24-0.46 0.13-0.23 GIPY 6.00-3.00 6.00 3.00 0.02 0.050 5.00 • • • • • 0.26-0.55 0.15-0.27 GIPY 8.00-4.00 8.00 4.00 0.02 0.050 5.60 • • • • • 0.34-0.74 0.20-0.36 • Can cut arcs to 250° • DMIN for internal machining = 70 mm • For cutting speed recommendations and user guide, see pages 419-428, 432-436 (1) Cutting width tolerance (+/-) (2) Corner radius tolerance (+/-) For tools, see pages: Anti-Vibration Blades (284) • C#-GHDR/L (274) • CGFG 51-P8 (580) • CGHN 26-M (356) • CGHN 32-DGM (358) • CGHN 32-M (357) • CGHN-D (283) • CGHN-DG (283) • CGHN-P8 (283) • CGHN-S (282) • CGHR/L-P8DG (284) • CGPAD (281) • CGPAD-JHP (282) • GHDR/L (short pocket) (275) • GHDR/L-JHP (short pocket) (276) • GHDR/L-JHP-MC (short pocket) (277) • GHGR/L (278) • GHMPR/L (273) • GHMR/L (273) • GHSR/L (373) • GHSR/L-JHP-SL (374) • NQCH-GHSR/L-JHP (374) ±0.025 GIPA (W=3-6) Double-Ended Precision GroundInserts with a Polished Top 7° 15 Ref. 5 Rake for Machining Aluminum CW RE BW GIPA…D-ID5 Dimensions Tough 1 Hard Recommended Machining Data ap f turn f groove Designation CW RE CWTOL(2) RETOL(3) BW (mm) (mm/rev) (mm/rev) GIPA 3.00-0.20 3.00 0.20 0.02 0.030 2.40 • 0.25-1.80 0.12-0.20 0.08-0.14 GIPA 3.00-0.20-D (1) 3.00 0.20 0.02 0.030 2.40 • 0.25-1.80 0.12-0.25 0.09-0.16 GIPA 4.00-0.40 4.00 0.40 0.02 0.030 3.20 • 0.50-2.40 0.14-0.31 0.10-0.20 GIPA 5.00-0.40 5.00 0.40 0.02 0.030 4.00 • 0.50-3.00 0.16-0.34 0.11-0.23 GIPA 6.00-0.40 6.00 0.40 0.02 0.030 4.80 • 0.50-3.60 0.19-0.41 0.11-0.26 • DMIN for internal machining = 70 mm • For cutting speed recommendations and user guide, see pages 419-428, 432-436 (1) Single-ended PCD tipped insert (2) Cutting width tolerance (+/-) (3) Corner radius tolerance (+/-) For tools, see pages: Anti-Vibration Blades (284) • C#-GHDR/L (274) • CGHN 26-M (356) • CGHN 32-DGM (358) • CGHN 32-M (357) • CGHN-D (283) • CGHN-DG (283) • CGHN-S (282) • CGPAD (281) • CGPAD-JHP (282) • GHDR/L (short pocket) (275) • GHDR/L-JHP (short pocket) (276) • GHDR/L-JHP-MC (short pocket) (277) • GHGR/L (278) • GHMPR/L (273) • GHMR/L (273) • GHSR/L (373) • GHSR/L-JHP-SL (374) • NQCH-GHSR/L-JHP (374) ±0.1 30 Ref. GDMA Utility Double-Ended Insert 7° 6.4 with a Polished Top Rake for Machining Aluminum CW RE BW Can cut arcs to 250° Dimensions Tough 1 Hard Recommended Machining Data ap f turn f groove Designation CW RE CWTOL(1) RETOL(2) BW (mm) (mm/rev) (mm/rev) GDMA 840 8.00 4.00 0.05 0.050 5.60 • • 0.00-4.00 0.24-0.67 0.14-0.38 • For heavy-duty machining • DMIN for internal machining = 65 mm • For cutting speed recommendations and user guide, see pages 419-428, 432-436 (1) Cutting width tolerance (+/-) (2) Corner radius tolerance (+/-) For tools, see pages: GADR/L-8 (286) • GADR/L-JHP (287) • GAFG-R/L-8 (580) • GHDKR/L (446) • GHIFR/L-A (445) • GHIR/L (W=7.0-8.3) (355) • GHIUR/L-C-A (15° & 27.5°) Bars (444) • GHIUR/L-UC (444) 300 ISCAR

Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar инструментальная оснастка 2022

Каталог Iscar инструментальная оснастка 2022