Каталог Iscar обработка канавок 2022 - страница 37

Навигация

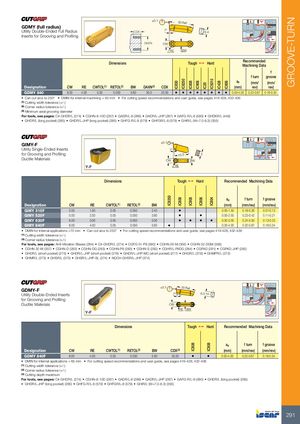

IC8250 IC830 IC808 IC8250 IC808IC908IC808 IC908 IC806 IC20 IC908 IC5010IC804 IC428 IC806 GROOVE-TURN ±0.1 30 Ref. GDMY (full radius) Utility Double-Ended Full Radius CDX 7° 6.4 Inserts for Grooving and Profiling DAXN CW RE BW Dimensions Tough 1 Hard RecommendedMachining Data f f turn groove ap (mm/ (mm/ Designation CW RE CWTOL(1) RETOL(2) BW DAXN(3) CDX (mm) rev) rev) GDMY 840 8.00 4.00 0.05 0.050 5.60 50.0 25.00 • • • • • • • • 0.00-4.00 0.32-0.67 0.18-0.34 • Can cut arcs to 250° • DMIN for internal machining = 65 mm • For cutting speed recommendations and user guide, see pages 419-428, 432-436 (1) Cutting width tolerance (+/-) (2) Corner radius tolerance (+/-) (3) Minimum axial grooving diameter For tools, see pages: C#-GHDR/L (274) • CGHN-8-10D (287) • GADR/L-8 (286) • GADR/L-JHP (287) • GAFG-R/L-8 (580) • GHDKR/L (446) • GHDR/L (long pocket) (285) • GHDR/L-JHP (long pocket) (285) • GHFG-R/L-8 (579) • GHFGR/L-8 (579) • GHIR/L (W=7.0-8.3) (355) GIMY-F ±0.1 Utility Single-Ended Inserts 7° for Grooving and Profiling 15.3 5 Ductile Materials CW BW RE Dimensions Tough 1 Hard Recommended Machining Data ap f turn f groove Designation CW RE CWTOL(1) RETOL(2) BW (mm) (mm/rev) (mm/rev) GIMY 315F 3.00 1.50 0.05 0.050 2.40 • 0.00-1.50 0.18-0.26 0.07-0.13 GIMY 525F 5.00 2.50 0.05 0.050 3.90 • • 0.00-2.50 0.23-0.42 0.11-0.21 GIMY 630F 6.00 3.00 0.05 0.050 5.00 • • • • 0.00-3.00 0.24-0.50 0.13-0.25 GIMY 840F 8.00 4.00 0.05 0.050 5.60 • 0.00-4.00 0.32-0.67 0.18-0.34 • DMIN for internal applications =70 mm • Can cut arcs to 250° • For cutting speed recommendations and user guide, see pages 419-428, 432-436 (1) Cutting width tolerance (+/-) (2) Corner radius tolerance (+/-) For tools, see pages: Anti-Vibration Blades (284) • C#-GHDR/L (274) • CGFG 51-P8 (580) • CGHN 26-M (356) • CGHN 32-DGM (358) • CGHN 32-M (357) • CGHN-D (283) • CGHN-DG (283) • CGHN-P8 (283) • CGHN-S (282) • CGHR/L-P8DG (284) • CGPAD (281) • CGPAD-JHP (282) • GHDR/L (short pocket) (275) • GHDR/L-JHP (short pocket) (276) • GHDR/L-JHP-MC (short pocket) (277) • GHGR/L (278) • GHMPR/L (273) • GHMR/L (273) • GHSR/L (373) • GHSR/L-JHP-SL (374) • NQCH-GHSR/L-JHP (374) GDMY-F ±0.1 30 Ref. Utility Double-Ended Inserts 7º 6.3 Ref. for Grooving and Profiling Ductile Materials CW RE BW Dimensions Tough 1 Hard Recommended Machining Data ap f turn f groove Designation CW RE CWTOL(1) RETOL(2) BW CDX(3) (mm) (mm/rev) (mm/rev) GDMY 840F 8.00 4.00 0.05 0.050 5.60 25.00 • • 0.00-4.00 0.32-0.67 0.18-0.34 • DMIN for internal applications = 65 mm • For cutting speed recommendations and user guide, see pages 419-428, 432-436 (1) Cutting width tolerance (+/-) (2) Corner radius tolerance (+/-) (3) Cutting depth maximum For tools, see pages: C#-GHDR/L (274) • CGHN-8-10D (287) • GADR/L-8 (286) • GADR/L-JHP (287) • GAFG-R/L-8 (580) • GHDR/L (long pocket) (285) • GHDR/L-JHP (long pocket) (285) • GHFG-R/L-8 (579) • GHFGR/L-8 (579) • GHIR/L (W=7.0-8.3) (355) 291

Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar инструментальная оснастка 2022

Каталог Iscar инструментальная оснастка 2022