Каталог Iscar монолитные сверла 2022 - страница 23

Навигация

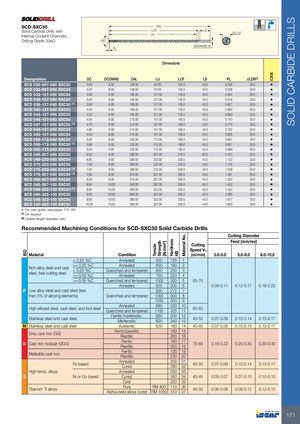

ISO Tensile Strength [N/mm2] Hardness HB Material No. IC908 SOLID CARBIDE DRILLS SCD-SXC30 OAL Solid Carbide Drills withInternal Coolant Channels, LCF LSLU DC h7 Drilling Depth 30xD 135 DCONMS h6 PL Dimensions Designation DC DCONMS OAL LU LCF LS PL ULDR(2) SCD 030-097-060 SXC30 3.00 6.00 150.00 97.00 105.0 40.0 0.495 30.0 • SCD 032-097-060 SXC30 3.20 6.00 150.00 97.00 105.0 40.0 0.528 30.0 • SCD 033-127-060 SXC30 3.30 6.00 185.00 127.00 135.0 45.0 0.544 30.0 • SCD 035-127-060 SXC30 3.50 6.00 185.00 127.00 135.0 45.0 0.578 30.0 • SCD 038-127-060 SXC30 (1) 3.80 6.00 185.00 127.00 135.0 45.0 0.627 30.0 • SCD 040-127-060 SXC30 4.00 6.00 185.00 127.00 135.0 45.0 0.660 30.0 • SCD 042-127-060 SXC30 4.20 6.00 185.00 127.00 135.0 45.0 0.693 30.0 • SCD 045-157-060 SXC30 4.50 6.00 215.00 157.00 165.0 45.0 0.743 30.0 • SCD 047-157-060 SXC30 (1) 4.70 6.00 215.00 157.00 165.0 45.0 0.775 30.0 • SCD 048-157-060 SXC30 4.80 6.00 215.00 157.00 165.0 45.0 0.792 30.0 • SCD 050-157-060 SXC30 5.00 6.00 215.00 157.00 165.0 45.0 0.825 30.0 • SCD 055-172-060 SXC30 5.50 6.00 230.00 172.00 180.0 45.0 0.907 30.0 • SCD 058-172-060 SXC30 (1) 5.80 6.00 230.00 172.00 180.0 45.0 0.957 30.0 • SCD 060-172-060 SXC30 6.00 6.00 230.00 172.00 180.0 45.0 0.990 30.0 • SCD 065-207-080 SXC30 6.50 8.00 280.00 207.00 215.0 60.0 1.072 30.0 • SCD 068-222-080 SXC30 6.80 8.00 280.00 222.00 230.0 45.0 1.122 30.0 • SCD 070-222-080 SXC30 7.00 8.00 280.00 222.00 230.0 45.0 1.155 30.0 • SCD 075-222-080 SXC30 (1) 7.50 8.00 280.00 222.00 230.0 45.0 1.238 30.0 • SCD 078-257-080 SXC30 (1) 7.80 8.00 315.00 257.00 265.0 45.0 1.287 30.0 • SCD 080-257-080 SXC30 8.00 8.00 315.00 257.00 265.0 45.0 1.320 30.0 • SCD 085-287-100 SXC30 8.50 10.00 350.00 287.00 295.0 50.0 1.402 30.0 • SCD 088-322-100 SXC30 (1) 8.80 10.00 380.00 322.00 330.0 45.0 1.452 30.0 • SCD 090-322-100 SXC30 9.00 10.00 380.00 322.00 330.0 45.0 1.485 30.0 • SCD 098-322-100 SXC30 9.80 10.00 380.00 322.00 330.0 45.0 1.617 30.0 • SCD 100-322-100 SXC30 10.00 10.00 380.00 322.00 330.0 45.0 1.650 30.0 • • For user guide, see pages 175-184 (1) On request (2) Usable length diameter ratio Recommended Machining Conditions for SCD-SXC30 Solid Carbide Drills Cutting Diameter Feed (mm/rev) Cutting Speed Vc Material Condition (m/min) 3.0-5.0 5.0-8.0 8.0-10.0 < 0.25 %C Annealed 420 125 1 Non-alloy steel and caststeel, free cutting steel>= 0.25 %C< 0.55 %C>= 0.55 %CAnnealed650 190 2Quenched and tempered8502503Annealed7502204 >= 0.55 %C Quenched and tempered 1000 300 5 65-70 Annealed 600 200 6 0.09-0.11 0.12-0.17 0.18-0.22 P Low alloy steel and cast steel (less 930 275 7 than 5% of alloying elements) Quenched and tempered 1000 300 8 1200 350 9 High alloyed steel, cast steel, and tool steel AnnealedQuenched and tempered6801100 200 1032511 60-65 Stainless steel and cast steel Ferritic/martensitic.Martensitic680820 200 1224013 45-50 0.07-0.09 0.10-0.14 0.13-0.17 M Stainless steel and cast steel Austenitic 600 180 14 40-45 0.07-0.09 0.10-0.14 0.13-0.17 Grey cast iron (GG) Ferritic/pearlitic 180 15Pearlitic26016 K Cast iron nodular (GGG) FerriticPearlitic 160 1725018 75-85 0.18-0.22 0.20-0.30 0.30-0.40 Malleable cast iron Ferritic 130 19Pearlitic23020 Fe based AnnealedCured 200 3128032 45-50 0.07-0.09 0.10-0.14 0.13-0.17 High temp. alloys Annealed 250 33 S Ni or Co based Cured 350 34 40-45 0.05-0.07 0.07-0.10 0.10-0.13 Cast 320 35 Titanium Ti alloys Pure RM 400 110 36Alpha+beta alloys curedRM 10503103745-500.06-0.080.08-0.120.12-0.15 171

Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar сверла со сменной режущей частью 2022

Каталог Iscar сверла со сменной режущей частью 2022 Каталог Iscar токарный инструмент для нарезания канавок

Каталог Iscar токарный инструмент для нарезания канавок Каталог Iscar отрезка 2022

Каталог Iscar отрезка 2022 Руководство Iscar режущий инструмент в производстве штампов и пресс-форм

Руководство Iscar режущий инструмент в производстве штампов и пресс-форм