Каталог Iscar монолитные сверла 2022 - страница 10

Навигация

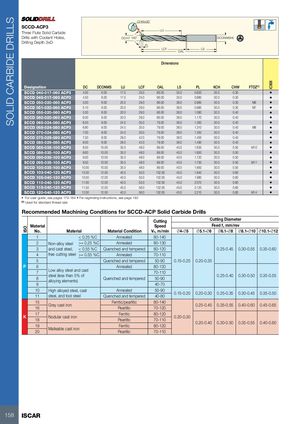

SOLID CARBIDE DRILLS ISO IC908 CHWx30˚ SCCD-ACP3 Three Flute Solid Carbide LU Drills with Coolant Holes, DCm7 140˚ DCONMSh6 Drilling Depth 3xD PL LCF LS OAL Dimensions Designation DC DCONMS LU LCF OAL LS PL KCH CHW FTDZ(1) SCCD 040-017-060 ACP3 4.00 6.00 17.0 25.0 66.00 35.0 0.820 30.0 0.30 • SCCD 045-017-060 ACP3 4.50 6.00 17.0 25.0 66.00 35.0 0.880 30.0 0.30 • SCCD 050-020-060 ACP3 5.00 6.00 20.0 29.0 66.00 36.0 0.960 30.0 0.30 M6 • SCCD 051-020-060 ACP3 5.10 6.00 20.0 29.0 66.00 36.0 0.980 30.0 0.30 M7 • SCCD 055-020-060 ACP3 5.50 6.00 20.0 29.0 66.00 36.0 1.080 30.0 0.40 • SCCD 060-020-060 ACP3 6.00 6.00 20.0 29.0 66.00 36.0 1.170 30.0 0.40 • SCCD 065-024-080 ACP3 6.50 8.00 24.0 35.0 79.00 36.0 1.260 30.0 0.40 • SCCD 068-024-080 ACP3 6.80 8.00 24.0 35.0 79.00 36.0 1.310 30.0 0.40 M8 • SCCD 070-024-080 ACP3 7.00 8.00 24.0 35.0 79.00 36.0 1.350 30.0 0.40 • SCCD 075-029-080 ACP3 7.50 8.00 29.0 42.0 79.00 36.0 1.400 30.0 0.40 • SCCD 080-029-080 ACP3 8.00 8.00 29.0 42.0 79.00 36.0 1.490 30.0 0.40 • SCCD 085-035-100 ACP3 8.50 10.00 35.0 48.0 89.00 40.0 1.630 30.0 0.50 M10 • SCCD 086-035-100 ACP3 8.60 10.00 35.0 48.0 89.00 40.0 1.650 30.0 0.50 • SCCD 090-035-100 ACP3 9.00 10.00 35.0 48.0 89.00 40.0 1.720 30.0 0.50 • SCCD 095-035-100 ACP3 9.50 10.00 35.0 48.0 89.00 40.0 1.750 30.0 0.50 M11 • SCCD 100-035-100 ACP3 10.00 10.00 35.0 48.0 89.00 40.0 1.850 30.0 0.50 • SCCD 103-040-120 ACP3 10.30 12.00 40.0 55.0 102.00 45.0 1.940 30.0 0.60 • SCCD 105-040-120 ACP3 10.50 12.00 40.0 55.0 102.00 45.0 1.980 30.0 0.60 • SCCD 110-040-120 ACP3 11.00 12.00 40.0 55.0 102.00 45.0 2.070 30.0 0.60 • SCCD 115-040-120 ACP3 11.50 12.00 40.0 56.0 102.00 45.0 2.120 30.0 0.60 • SCCD 120-040-120 ACP3 12.00 12.00 40.0 56.0 102.00 45.0 2.210 30.0 0.60 M14 • • For user guide, see pages 175-184 • For regrinding instructions, see page 182 (1) Used for standard thread size Recommended Machining Conditions for SCCD-ACP Solid Carbide Drills Cutting Cutting Diameter Material Speed Feed f, mm/rev No. Material Material Condition Vc, m/min Ø4-Ø5 Ø5.1-Ø6 Ø6.1-Ø8 Ø8.1-Ø10 Ø10.1-Ø12 1 < 0.25 %C Annealed 80-140 2 Non-alloy steel >= 0.25 %C Annealed 80-130 3 and cast steel, < 0.55 %C Quenched and tempered 80-120 0.25-0.45 0.30-0.55 0.35-0.60 4 free cutting steel >= 0.55 %C Annealed 70-110 5 Quenched and tempered 50-90 0.15-0.25 0.20-0.35 P 6 Annealed 80-120 78 Low alloy steel and caststeel (less than 5% ofalloying elements) 70-110Quenched and tempered50-90 0.25-0.40 0.30-0.50 0.35-0.55 9 40-70 10 High alloyed steel, cast11steel, and tool steelAnnealed 50-90 0.15-0.20 0.20-0.30 0.25-0.35 0.30-0.45 0.35-0.50Quenched and tempered40-80 1516 Grey cast iron Ferritic/pearlitic 80-140Pearlitic70-120 0.25-0.45 0.35-0.55 0.40-0.60 0.45-0.65 K 1718 Nodular cast iron19 FerriticPearliticFerritic 80-12070-11080-1200.20-0.300.20-0.40 0.30-0.50 0.35-0.55 0.40-0.60 20 Malleable cast iron Pearlitic 70-110 158 ISCAR

Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar сверла со сменной режущей частью 2022

Каталог Iscar сверла со сменной режущей частью 2022 Каталог Iscar токарный инструмент для нарезания канавок

Каталог Iscar токарный инструмент для нарезания канавок Каталог Iscar отрезка 2022

Каталог Iscar отрезка 2022 Руководство Iscar режущий инструмент в производстве штампов и пресс-форм

Руководство Iscar режущий инструмент в производстве штампов и пресс-форм