Каталог Iscar монолитные фрезы 2022 - страница 34

Навигация

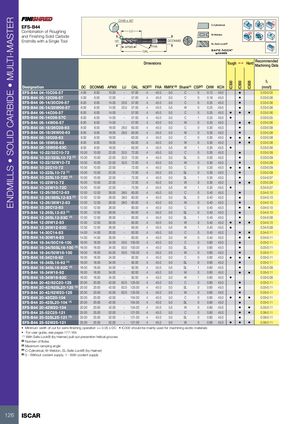

ENDMILLS • SOLID CARBIDE • MULTI-MASTER IC300 IC900 IC608 CHW x 45° Rd° EFS-B44 C-Cylindrical Combination of Roughing LU and Finishing Solid Carbide W-Weldon Endmills with a Single Tool DC DCONMS SL-Safe-Lock® APMX FHA OAL Dimensions Tough 1 Hard Recommended Machining Data fz Designation DC DCONMS APMX LU OAL NOF(2) FHA RMPX°(3) Shank(4) CSP(5) CHW KCH (mm/t) EFS-B44 04-10C06-57 4.00 6.00 10.00 - 57.00 4 45.0 5.0 C 0 0.12 45.0 • 0.03-0.05 EFS-B44 05-12C06-57 5.00 6.00 12.00 - 57.00 4 45.0 5.0 C 0 0.18 45.0 • 0.03-0.06 EFS-B44 06-14/20C06-57 6.00 6.00 14.00 20.0 57.00 4 45.0 5.0 C 0 0.25 45.0 • 0.03-0.06 EFS-B44 06-14/20W06-57 6.00 6.00 14.00 20.0 57.00 4 45.0 5.0 W 0 0.25 45.0 • 0.03-0.06 EFS-B44 06-14C06-57 6.00 6.00 14.00 - 57.00 4 45.0 5.0 C 0 0.25 45.0 • • • 0.03-0.06 EFS-B44 06-14C06-57C 6.00 6.00 14.00 - 57.00 4 45.0 5.0 C 1 0.25 45.0 • 0.03-0.05 EFS-B44 06-14W06-57 6.00 6.00 14.00 - 57.00 4 45.0 5.0 W 0 0.25 45.0 • • 0.03-0.06 EFS-B44 08-18/26C08-63 8.00 8.00 18.00 26.0 63.00 4 45.0 5.0 C 0 0.30 45.0 • 0.03-0.08 EFS-B44 08-18/26W08-63 8.00 8.00 18.00 26.0 63.00 4 45.0 5.0 W 0 0.30 45.0 • 0.03-0.08 EFS-B44 08-18C08-63 8.00 8.00 18.00 - 63.00 4 45.0 5.0 C 0 0.30 45.0 • • • 0.03-0.08 EFS-B44 08-18W08-63 8.00 8.00 18.00 - 63.00 4 45.0 5.0 W 0 0.30 45.0 • • 0.03-0.08 EFS-B44 08-18W08-63C 8.00 8.00 18.00 - 63.00 4 45.0 5.0 W 1 0.30 45.0 • 0.03-0.06 EFS-B44 10-22/32C10-72 10.00 10.00 22.00 32.0 72.00 4 45.0 5.0 C 0 0.30 45.0 • 0.03-0.09 EFS-B44 10-22/32SL10-72 (1) 10.00 10.00 22.00 32.0 72.00 4 45.0 5.0 SL 0 0.00 45.0 • 0.03-0.09 EFS-B44 10-22/32W10-72 10.00 10.00 22.00 32.0 72.00 4 45.0 5.0 W 0 0.30 45.0 • 0.03-0.09 EFS-B44 10-22C10-72 10.00 10.00 22.00 - 72.00 4 45.0 5.0 C 0 0.30 45.0 • • • 0.03-0.09 EFS-B44 10-22SL10-72 (1) 10.00 10.00 22.00 - 72.00 4 45.0 5.0 SL 0 0.30 45.0 • 0.03-0.09 EFS-B44 10-22SL10-72C (1) 10.00 10.00 22.00 - 72.00 4 45.0 5.0 SL 1 0.30 45.0 • 0.04-0.07 EFS-B44 10-22W10-72 10.00 10.00 22.00 - 72.00 4 45.0 5.0 W 0 0.30 45.0 • • 0.03-0.09 EFS-B44 10-22W10-72C 10.00 10.00 22.00 - 72.00 4 45.0 5.0 W 1 0.30 45.0 • 0.04-0.07 EFS-B44 12-26/38C12-83 12.00 12.00 26.00 38.0 83.00 4 45.0 5.0 C 0 0.40 45.0 • 0.04-0.10 EFS-B44 12-26/38SL12-83 (1) 12.00 12.00 26.00 38.0 83.00 4 45.0 5.0 SL 0 0.40 45.0 • 0.04-0.10 EFS-B44 12-26/38W12-83 12.00 12.00 26.00 38.0 83.00 4 45.0 5.0 W 0 0.40 45.0 • 0.04-0.10 EFS-B44 12-26C12-83 12.00 12.00 26.00 - 83.00 4 45.0 5.0 C 0 0.40 45.0 • • 0.04-0.10 EFS-B44 12-26SL12-83 (1) 12.00 12.00 26.00 - 83.00 4 45.0 5.0 SL 0 0.40 45.0 • 0.04-0.10 EFS-B44 12-26SL12-83C (1) 12.00 12.00 26.00 - 83.00 4 45.0 5.0 SL 1 0.40 45.0 • 0.04-0.08 EFS-B44 12-26W12-83 12.00 12.00 26.00 - 83.00 4 45.0 5.0 W 0 0.40 45.0 • • • 0.04-0.10 EFS-B44 12-26W12-83C 12.00 12.00 26.00 - 83.00 4 45.0 5.0 W 1 0.40 45.0 • 0.04-0.08 EFS-B44 14-30C14-83 14.00 14.00 30.00 - 83.00 4 45.0 5.0 C 0 0.40 45.0 • • 0.04-0.11 EFS-B44 14-30W14-83 14.00 14.00 30.00 - 83.00 4 45.0 5.0 W 0 0.40 45.0 • • 0.04-0.11 EFS-B44 16-34/50C16-100 16.00 16.00 34.00 50.0 100.00 4 45.0 5.0 C 0 0.60 45.0 • 0.05-0.11 EFS-B44 16-34/50SL16-100 (1) 16.00 16.00 34.00 50.0 100.00 4 45.0 5.0 SL 0 0.60 45.0 • 0.05-0.11 EFS-B44 16-34/50W16-100 16.00 16.00 34.00 50.0 100.00 4 45.0 5.0 W 0 0.60 45.0 • 0.05-0.11 EFS-B44 16-34C16-92 16.00 16.00 34.00 - 92.00 4 45.0 5.0 C 0 0.60 45.0 • • • 0.05-0.11 EFS-B44 16-34SL16-92 (1) 16.00 16.00 34.00 - 92.00 4 45.0 5.0 SL 0 0.60 45.0 • 0.05-0.11 EFS-B44 16-34SL16-92C (1) 16.00 16.00 34.00 - 92.00 4 45.0 5.0 SL 1 0.60 45.0 • 0.05-0.08 EFS-B44 16-34W16-92 16.00 16.00 34.00 - 92.00 4 45.0 5.0 W 0 0.60 45.0 • • 0.05-0.11 EFS-B44 16-34W16-92C 16.00 16.00 34.00 - 92.00 4 45.0 5.0 W 1 0.60 45.0 • 0.05-0.08 EFS-B44 20-42/62C20-125 20.00 20.00 42.00 62.0 125.00 4 45.0 5.0 C 0 0.60 45.0 • 0.05-0.11 EFS-B44 20-42/62SL20-125 (1) 20.00 20.00 42.00 62.0 125.00 4 45.0 5.0 SL 0 0.60 45.0 • 0.05-0.11 EFS-B44 20-42/62W20-125 20.00 20.00 42.00 62.0 125.00 4 45.0 5.0 W 0 0.60 45.0 • 0.05-0.11 EFS-B44 20-42C20-104 20.00 20.00 42.00 - 104.00 4 45.0 5.0 C 0 0.60 45.0 • • • 0.05-0.11 EFS-B44 20-42SL20-104 (1) 20.00 20.00 42.00 - 104.00 4 45.0 5.0 SL 0 0.60 45.0 • 0.05-0.11 EFS-B44 20-42W20-104 20.00 20.00 42.00 - 104.00 4 45.0 5.0 W 0 0.60 45.0 • • 0.05-0.11 EFS-B44 25-52C25-121 25.00 25.00 52.00 - 121.00 4 45.0 5.0 C 0 0.60 45.0 • • 0.06-0.11 EFS-B44 25-52SL25-121 (1) 25.00 25.00 52.00 - 121.00 4 45.0 5.0 SL 0 0.60 45.0 • 0.06-0.11 EFS-B44 25-52W25-121 25.00 25.00 52.00 - 121.00 4 45.0 5.0 W 0 0.60 45.0 • • • 0.06-0.11 • Minimum width of cut for semi-finishing operation >= 0.05 x DC • IC300 should be mainly used for machining exotic materials • For user guide, see pages 177-184 (1) With Safe-Lock® (by Haimer) pull-out prevention helical grooves (2) Number of flutes (3) Maximum ramping angle (4) C-Cylindrical, W-Weldon, SL-Safe-Lock® (by Haimer) (5) 0 - Without coolant supply, 1 - With coolant supply 126 ISCAR

Каталог Iscar торцевые фрезы 2022

Каталог Iscar торцевые фрезы 2022 Каталог Iscar инструмент для нарезания резьбы

Каталог Iscar инструмент для нарезания резьбы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar инструмент для токарной обработки

Каталог Iscar инструмент для токарной обработки Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar сверла со сменной режущей частью 2022

Каталог Iscar сверла со сменной режущей частью 2022