Каталог Iscar монолитные фрезы 2022 - страница 30

Навигация

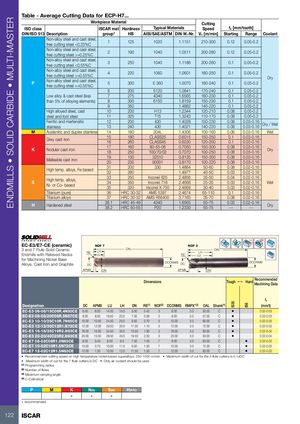

ENDMILLS • SOLID CARBIDE • MULTI-MASTER IS35 IS6 Table - Average Cutting Data for ECP-H7... Workpiece Material Cutting ISO class ISCAR mat Hardness Typical Materials Speed fz [mm/tooth] DIN/ISO 513 Description group* HB AISI/SAE/ASTM DIN W.-Nr. Vc [m/min] Starting Range Coolant Non-alloy steel and cast steel,free cutting steel <0.25%C1125 1020 1.1151 210-300 0.12 0.05-0.2 Non-alloy steel and cast steel,free cutting steel >=0.25%C2190 1040 1.0511 200-280 0.12 0.05-0.2 Non-alloy steel and cast steel,free cutting steel <0.55%C3250 1040 1.1186 200-260 0.1 0.05-0.2 Non-alloy steel and cast steel,free cutting steel >=0.55%C4220PNon-alloy steel and cast steel,free cutting steel >=0.55%C530010601.0601180-2500.10.05-0.2 DryE 3601.0070180-2400.10.05-0.2 6 200 5120 1.0841 170-240 0.1 0.05-0.2 Low alloy & cast steel (less 7 275 4340 1.6565 160-230 0.1 0.05-0.2 than 5% of alloying elements) 8 300 6150 1.8159 150-230 0.1 0.05-0.2 9 350 1.4882 140-220 0.1 0.05-0.2 High alloyed steel, cast 10 200 H13 1.2344 120-210 0.08 0.05-0.2 steel and tool steel 11 325 T15 1.3243 110-170 0.08 0.05-0.2 Ferritic and martensiticstainless 12 20013240 420430 1.4028 150-2301.4021140-2200.080.080.03-0.160.03-0.16 Dry / Wet M Austenitic and duplex stainless 14 180 304L 1.4306 100-160 0.06 0.03-0.16 Wet Grey cast iron 15 180 CLASS25 0.6015 150-250 0.1 0.03-0.1616260CLASS450.6030120-2000.10.03-0.16 K Nodular cast iron 1718 160250 80-55-06100/70/03 0.7050 150-3000.7070100-2500.080.080.03-0.160.03-0.16 Dry Malleable cast iron 19 130 32510 0.8135 150-300 0.08 0.03-0.1620230900010.8170100-2200.080.03-0.16 High temp. alloys, Fe-based 3132 200280 330 1.4864 50-60 0.08 0.02-0.161.497740-500.030.02-0.16 S High temp. alloys,Ni- or Co- based 33 250 Inconel 625 2.4856 35-50 0.04 0.02-0.1634350Inconel 7182.466825-350.030.02-0.16 Wet35320Inconel X-7502.466930-400.030.02-0.16 Titanium (pure) 36 HRC 30-32 AMS 5397 2.4674 65-110 0.1 0.02-0.16 Titanium alloys 37 HRC 30-32 AMS R56400 3.7165 35-70 0.08 0.02-0.16 H Hardened steel 38.1 HRC 45-49 434038.2HRC 50-55P201.6565 55-751.233055-750.03--- 0.02-0.16--- Dry Rd° EC-E3/E7-CE (ceramic) NOF 7 NOF 3 3 and 7 Flute Solid CeramicEndmills with Relieved NecksRELHLU OAL OALLHRELU for Machining Nickel Base Alloys, Cast Iron and Graphite DC DCONMS DC DCONMS APMX DN APMX DN Dimensions Tough 1 Hard Recommended Machining Data fz Designation DC APMX LU LH DN RE(1) NOF(2) DCONMS RMPX°(3) OAL Shank(4) (mm/t) EC-E3 06-06/15C06R.4N50CE 6.00 6.00 14.50 15.0 5.50 0.42 3 6.00 3.0 50.00 C • 0.02-0.03 EC-E3 08-08/20C08R.5N57CE 8.00 8.00 19.50 20.0 7.50 0.56 3 8.00 3.0 57.00 C • 0.02-0.03 EC-E3 10-10/25C10R.7N65CE 10.00 10.00 24.50 25.0 9.50 0.70 3 10.00 3.0 65.00 C • 0.02-0.03 EC-E3 12-12/30C12R1.N72CE 12.00 12.00 29.50 30.0 11.50 1.10 3 12.00 3.0 72.00 C • 0.02-0.03 EC-E3 16-16/35C16R2.N83CE 16.00 16.00 34.50 35.0 15.50 1.90 3 16.00 3.0 83.00 C • 0.02-0.04 EC-E3 20-20/40C20R2.N93CE 20.00 15.00 39.50 40.0 19.50 2.50 3 20.00 3.0 93.00 C • 0.02-0.04 EC-E7 08-02C08R1.0N63CE 8.00 0.40 8.00 9.5 7.50 1.00 7 8.00 3.0 63.00 C • 0.02-0.03 EC-E7 10-02C10R1.5N72CE 10.00 0.70 10.00 11.5 9.50 1.50 7 10.00 3.0 72.00 C • 0.02-0.03 EC-E7 12-02C12R1.5N83CE 12.00 1.30 10.00 12.0 11.50 1.50 7 12.00 3.0 83.00 C • 0.02-0.03 • Recommended cutting speed on high temperature nickel-based superalloys: 250-1000 m/min • Maximum width of cut for the 3 flute cutters is 0.1xDC • Maximum width of cut for the 7 flute cutters is DC • Only air coolant should be used (1) Programming radius (2) Number of flutes (3) Maximum ramping angle (4) C-Cylindrical P M K N(K) S(M) H(P/K) + + + + recommended 122 ISCAR

Каталог Iscar торцевые фрезы 2022

Каталог Iscar торцевые фрезы 2022 Каталог Iscar инструмент для нарезания резьбы

Каталог Iscar инструмент для нарезания резьбы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar инструмент для токарной обработки

Каталог Iscar инструмент для токарной обработки Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar сверла со сменной режущей частью 2022

Каталог Iscar сверла со сменной режущей частью 2022