Каталог Iscar монолитные фрезы 2022 - страница 21

Навигация

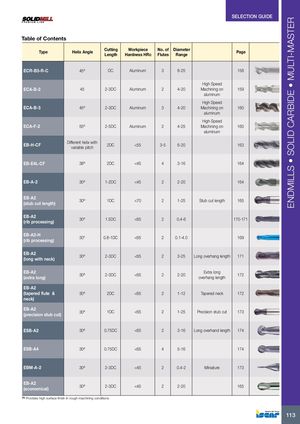

ENDMILLS • SOLID CARBIDE • MULTI-MASTER SELECTION GUIDE Table of Contents Type Helix Angle Cutting Workpiece No. of DiameterLengthHardness HRcFlutesRangePage ECR-B3-R-C 45º DC Aluminum 3 8-25 158 High Speed ECA-B-2 45 2-3DC Aluminum 2 4-20 Machining on 159 aluminum High Speed ECA-B-3 45º 2-3DC Aluminum 3 4-20 Machining on 160 aluminum High Speed ECA-F-2 55º 2-5DC Aluminum 2 4-25 Machining on 160 aluminum EB-H-CF Different helix withvariable pitch2DC <55 3-5 6-20 163 EB-E4L-CF 38º 2DC <45 4 3-16 164 EB-A-2 30º 1-2DC <45 2 2-20 164 EB-A2(stub cut length) 30º 1DC <70 2 1-25 Stub cut length 165 EB-A2(rib processing) 30º 1.5DC <65 2 0.4-6 170-171 EB-A2-H(rib processing) 30° 0.8-1DC <65 2 0.1-4.0 169 EB-A2(long with neck) 30º 2-3DC <65 2 3-25 Long overhang length 171 EB-A2(extra long) 30º 2-3DC <65 2 2-20 Extra longoverhang length172 EB-A2 (tapered flute & 30º 2DC <65 2 1-12 Tapered neck 172 neck) EB-A2(precision stub cut) 30º 1DC <65 2 1-25 Precision stub cut 173 ESB-A2 30º 0.75DC <65 2 3-16 Long overhand length 174 ESB-A4 30º 0.75DC <65 4 5-16 174 EBM-A-2 30º 2-3DC <45 2 0.4-2 Miniature 173 EB-A2(economical) 30º 2-3DC <45 2 2-20 165 (1) Provides high surface finish in rough machining conditions 113

Каталог Iscar торцевые фрезы 2022

Каталог Iscar торцевые фрезы 2022 Каталог Iscar инструмент для нарезания резьбы

Каталог Iscar инструмент для нарезания резьбы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar инструмент для токарной обработки

Каталог Iscar инструмент для токарной обработки Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar сверла со сменной режущей частью 2022

Каталог Iscar сверла со сменной режущей частью 2022