Каталог Iscar монолитные фрезы 2022 - страница 19

Навигация

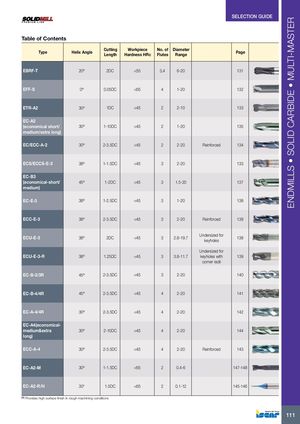

ENDMILLS • SOLID CARBIDE • MULTI-MASTER SELECTION GUIDE Table of Contents Type Helix Angle Cutting Workpiece No. of DiameterLengthHardness HRcFlutesRangePage EBRF-T 20º 2DC <55 3,4 6-20 131 EFF-S 0º 0.05DC <65 4 1-20 132 ETR-A2 30º 1DC <45 2 2-10 133 EC-A2 (economical short/ 30º 1-10DC <45 2 1-20 135 medium/extra long) EC/ECC-A-2 30º 2-3.5DC <45 2 2-20 Reinforced 134 ECS/ECCS-E-3 38º 1-1.5DC <45 3 2-20 133 EC-B3 (economical-short/ 45º 1-2DC <45 3 1.5-20 137 medium) EC-E-3 38º 1-2.5DC <45 3 1-20 138 ECC-E-3 38º 2-3.5DC <45 3 2-20 Reinforced 139 ECU-E-3 38º 2DC <45 3 2.8-19.7 Undersized forkeyholes138 Undersized for ECU-E-3-R 38º 1.25DC <45 3 3.8-11.7 keyholes with 139 corner radii EC-B-3/3R 45º 2-3.5DC <45 3 2-20 140 EC-B-4/4R 45º 2-3.5DC <45 4 2-20 141 EC-A-4/4R 30º 2-3.5DC <45 4 2-20 142 EC-A4(economical- medium&extra 30º 2-10DC <45 4 2-20 144 long) ECC-A-4 30º 2-3.5DC <45 4 2-20 Reinforced 143 EC-A2-M 30º 1-1.5DC <65 2 0.4-6 147-148 EC-A2-R/H 30° 1.5DC <65 2 0.1-12 145-146 (1) Provides high surface finish in rough machining conditions 111

Каталог Iscar торцевые фрезы 2022

Каталог Iscar торцевые фрезы 2022 Каталог Iscar инструмент для нарезания резьбы

Каталог Iscar инструмент для нарезания резьбы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar инструмент для токарной обработки

Каталог Iscar инструмент для токарной обработки Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar сверла со сменной режущей частью 2022

Каталог Iscar сверла со сменной режущей частью 2022