Каталог Iscar монолитные фрезы 2022 - страница 17

Навигация

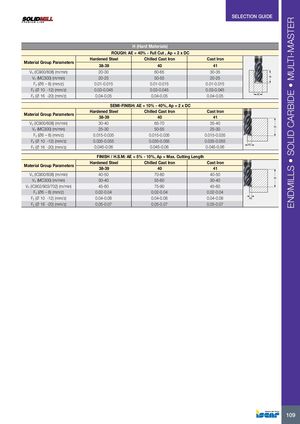

ENDMILLS • SOLID CARBIDE • MULTI-MASTER SELECTION GUIDE H (Hard Materials) ROUGH: AE = 40% - Full Cut , Ap = 2 x DC Hardened Steel Chilled Cast Iron Cast Iron Material Group Parameters 38-39 40 41 Vc (IC900/608) (m/min) 20-30 60-65 30-35 Vc (MC300) (m/min) 20-25 50-55 20-25 ap Fz (Ø6 – 8) (mm/z) 0.01-0.015 0.01-0.015 0.01-0.015 Fz (Ø 10 -12) (mm/z) 0.03-0.045 0.03-0.045 0.03-0.045 Fz (Ø 16 -20) (mm/z) 0.04-0.05 0.04-0.05 0.04-0.05 AE SEMI-FINISH: AE = 10% - 40%, Ap = 2 x DC Material Group Parameters Hardened Steel38-39 Chilled Cast Iron40 Cast Iron41 Vc (IC900/608) (m/min) 30-40 65-70 35-40 ap Vc (MC300) (m/min) 25-30 50-55 25-30 Fz (Ø6 – 8) (mm/z) 0.015-0.035 0.015-0.035 0.015-0.035 Fz (Ø 10 -12) (mm/z) 0.035-0.055 0.035-0.055 0.035-0.055 AE Fz (Ø 16 -20) (mm/z) 0.045-0.06 0.045-0.06 0.045-0.06 FINISH / H.S.M: AE = 5% - 10%, Ap = Max. Cutting Length Hardened Steel Chilled Cast Iron Cast Iron Material Group Parameters 38-39 40 41 Vc (IC900/608) (m/min) 40-50 70-80 40-50 ap Vc (MC300) (m/min) 30-40 55-60 30-40 Vc (IC902/903/702) (m/min) 45-60 75-90 45-60 Fz (Ø6 – 8) (mm/z) 0.02-0.04 0.02-0.04 0.02-0.04 Fz (Ø 10 -12) (mm/z) 0.04-0.06 0.04-0.06 0.04-0.06 AE Fz (Ø 16 -20) (mm/z) 0.05-0.07 0.05-0.07 0.05-0.07 109

Каталог Iscar торцевые фрезы 2022

Каталог Iscar торцевые фрезы 2022 Каталог Iscar инструмент для нарезания резьбы

Каталог Iscar инструмент для нарезания резьбы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar инструмент для токарной обработки

Каталог Iscar инструмент для токарной обработки Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar сверла со сменной режущей частью 2022

Каталог Iscar сверла со сменной режущей частью 2022