Каталог Iscar монолитные фрезы 2022 - страница 10

Навигация

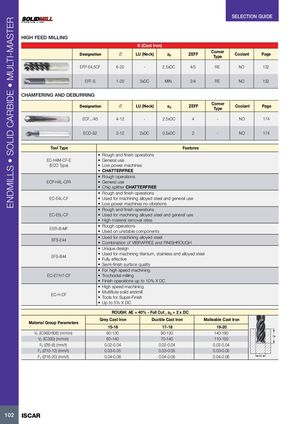

ENDMILLS • SOLID CARBIDE • MULTI-MASTER SELECTION GUIDE HIGH FEED MILLING K (Cast Iron) Designation Ø LU (Neck) ap ZEFF CornerType Coolant Page EFP-E4,5CF 6-20 - 2.5xDC 4/5 RE NO 132 EFF-S 1-20 3xDC MIN. 2/4 RE NO 132 CHAMFERING AND DEBURRING Designation Ø LU (Neck) ap ZEFF CornerType Coolant Page ECF.../45 4-12 - 2.5xDC 4 - NO 174 ECD-S2 3-12 2xDC 0.5xDC 2 - NO 174 Tool Type Features • Rough and finish operations EC-H4M-CF-E • General use (ECO Type) • Low power machines • CHATTERFREE • Rough operations ECP-H4L-CFR • General use • Chip splitter CHATTERFREE • Rough and finish operations EC-E4L-CF • Used for machining alloyed steel and general use • Low power machines no vibrations • Rough and finish operations EC-E5L-CF • Used for machining alloyed steel and general use • High material removal rates ECR-B-MF • Rough operations•Used on unstable components EFS-E44 • Used for machining alloyed steel•Combination ofVIBRAFREE and FINISHROUGH • Unique design EFS-B44 • Used for machining titanium, stainless and alloyed steel•Fully effective • Semi-finish surface quality • For high speed machining EC-E7/H7-CF • Trochoidal milling • Finish operations up to 10% X DC • High speed machining EC-H-CF • Multiflute solid endmill•Tools for Super-Finish • Up to 5% X DC ROUGH: AE = 40% - Full Cut , ap = 2 x DC Material Group Parameters Grey Cast Iron Ductile Cast Iron Malleable Cast Iron 15-16 17-18 19-20 Vc (IC900/608) (m/min) 80-130 90-130 140-180 ap Vc (IC300) (m/min) 60-140 70-140 110-150 Fz (Ø6–8) (mm/t) 0.02-0.04 0.02-0.04 0.02-0.04 Fz (Ø10-12) (mm/t) 0.03-0.05 0.03-0.05 0.03-0.05 Fz (Ø16-20) (mm/t) 0.04-0.06 0.04-0.06 0.04-0.06 AE 102 ISCAR

Каталог Iscar торцевые фрезы 2022

Каталог Iscar торцевые фрезы 2022 Каталог Iscar инструмент для нарезания резьбы

Каталог Iscar инструмент для нарезания резьбы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar инструмент для токарной обработки

Каталог Iscar инструмент для токарной обработки Каталог Iscar инструмент для обработки алюминиевых колёс

Каталог Iscar инструмент для обработки алюминиевых колёс Каталог Iscar сверла со сменной режущей частью 2022

Каталог Iscar сверла со сменной режущей частью 2022