Каталог Iscar концевые фрезы со сменными пластинами 2022 - страница 62

Навигация

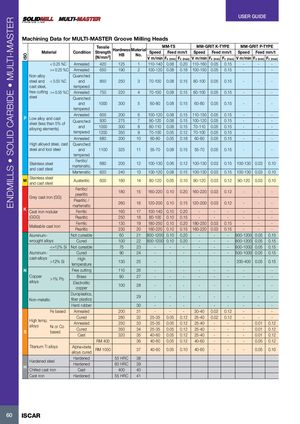

ENDMILLS • SOLID CARBIDE • MULTI-MASTER ISO USER GUIDE Machining Data for MULTI-MASTER Groove Milling Heads Material Condition TensileStrength[N/mm2] MM-TSHardness MaterialHBNo.SpeedFeed mm/tV m/minFz (min)Fz (max)MM-GRIT K-TYPESpeedFeed mm/tV m/minFz (min)Fz (max)MM-GRIT P-TYPESpeedFeed mm/tVm/minFz(min)Fz(max) < 0.25 %C Annealed 420 125 1 110-140 0.08 0.20 110-160 0.05 0.15 - - - >= 0.25 %C Annealed 650 190 2 100-120 0.08 0.18 100-150 0.05 0.15 - - - Non-alloy Quenched steel and < 0.55 %C and 850 250 3 70-100 0.08 0.15 80-100 0.05 0.15 - - - cast steel, tempered free cutting >= 0.55 %C Annealed 750 220 4 70-100 0.08 0.15 80-100 0.05 0.15 - - - steel Quenched and 1000 300 5 60-80 0.08 0.15 60-80 0.05 0.15 - - - tempered Annealed 600 200 6 100-120 0.08 0.15 110-150 0.05 0.15 - - - P Low alloy and caststeel (less than 5% ofalloying elements)Quenchedandtempered93010001200275300350790-1200.080.15100-1200.050.15-880-1100.080.1570-1100.050.15-970-1000.050.1270-1000.050.15------- Annealed 680 200 10 60-80 0.05 0.18 60-80 0.05 0.15 - - - High alloyed steel, cast Quenched steel and tool steel and 1100 325 11 55-70 0.08 0.15 55-70 0.05 0.15 - - - tempered Stainless steel Ferritic/martensitic.680 200 12 100-130 0.06 0.12 100-130 0.03 0.15 100-130 0.03 0.10 and cast steel Martensitic 820 240 13 100-120 0.08 0.15 100-130 0.03 0.15 100-130 0.03 0.10 M Stainless steeland cast steelAustenitic 600 180 14 80-120 0.05 0.10 90-120 0.03 0.12 90-120 0.03 0.10 Ferritic/Grey cast iron (GG)pearliticPearlitic /martensitic18015160-2200.100.20160-2200.030.12 - - -26016120-2000.100.15120-2000.030.12--- K Cast iron nodular Ferritic 160 17 100-140 0.10 0.20 - - - - - - (GGG) Pearlitic 250 18 80-100 0.10 0.15 - - - - - - Malleable cast iron FerriticPearlitic 130 19 180-250 0.10 0.20 180-250 0.03 0.15 - - -23020160-2200.100.15160-2200.030.15--- Aluminum- Not cureable 60 21 800-1200 0.10 0.20 - - - 800-1200 0.05 0.15 wrought alloys Cured 100 22 800-1200 0.10 0.20 - - - 800-1200 0.05 0.15 <=12% Si Not cureable 75 23 - - - - - - 600-1000 0.05 0.15 Aluminum- Cured 90 24 - - - - - - 500-1000 0.05 0.15 cast-alloys >12% Si Hightemperature 130 25 - - - - - - 200-400 0.05 0.15 N Free cutting 110 26 - - - - - - - - - Copperalloys >1% Pb BrassElectroliticcopper 90 27 - - - - - - - - -10028--------- Duroplastics,Non-metallicfiber plastics29 - - - - - - - - - Hard rubber 30 - - - - - - - - - Fe based Annealed 200 31 - - - 30-40 0.02 0.12 - - - Cured 280 32 25-35 0.05 0.12 25-40 0.02 0.12 - - - High temp.alloysNi or CoSbasedAnnealedCured 250 33 25-35 0.05 0.12 25-40 - - - 0.01 0.123503425-350.050.1225-40---0.010.12 Cast 320 35 40-60 0.05 0.12 25-40 - - - 0.01 0.12 RM 400 36 40-60 0.05 0.12 40-60 - - - 0.05 0.12 Titanium Ti alloys Alpha+betaalloys curedRM 1050 37 40-60 0.05 0.10 40-60 - - - 0.05 0.10 Hardened steel Hardened 55 HRC 38 H Chilled cast iron HardenedCast 60 HRC 3940040 Cast iron Hardened 55 HRC 41 60 ISCAR

Каталог Iscar токарный инструмент

Каталог Iscar токарный инструмент Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar инструментальная оснастка 2022

Каталог Iscar инструментальная оснастка 2022