Каталог Iscar концевые фрезы со сменными пластинами 2022 - страница 18

Навигация

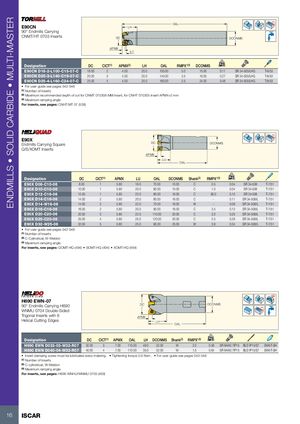

ENDMILLS • SOLID CARBIDE • MULTI-MASTER Rd° OAL E90CN LH 90° Endmills Carrying CNMT/HT 0703 Inserts DC DCONMS APMX 5.7 Designation DC CICT(1) APMX(2) LH OAL RMPX°(3) DCONMS kg E90CN D16-2-L100-C15-07-C 16.00 2 4.00 20.0 100.00 5.0 15.00 0.11 SR 34-505/LHG T-8/53 E90CN D20-3-L140-C19-07-C 20.00 3 4.00 20.0 140.00 3.5 19.00 0.27 SR 34-505/LHG T-8/53 E90CN D25-4-L160-C24-07-C 25.00 4 4.00 20.0 160.00 2.5 24.00 0.48 SR 34-505/LHG T-8/53 • For user guide see pages 542-548 (1) Number of inserts (2) Maximum recommended depth of cut for CNMT 070308-MM insert, for CNHT 070305 insert APMX=2 mm (3) Maximum ramping angle For inserts, see pages: CNHT/MT 07 (538) Rd° E90X Endmills Carrying Square DC DCONMS Q/S/XOMT Inserts APMX LU OAL Designation DC CICT(1) APMX LU OAL DCONMS Shank(2) RMPX°(3) kg E90X D08-C10-06 8.00 1 5.80 16.0 70.00 10.00 C 0.5 0.04 SR 34-508 T-7/51 E90X D10-C10-06 10.00 1 5.80 20.0 80.00 10.00 C 1.0 0.04 SR 34-508 T-7/51 E90X D12-C16-06 12.00 1 5.80 22.0 80.00 16.00 C 90.0 0.10 SR 34-508 T-7/51 E90X D14-C16-06 14.00 2 5.80 20.0 80.00 16.00 C - 0.11 SR 34-508/L T-7/51 E90X D14-W16-06 14.00 2 5.80 22.0 70.00 16.00 W - 0.09 SR 34-508/L T-7/51 E90X D16-C16-06 16.00 2 5.80 20.0 90.00 16.00 C 3.5 0.13 SR 34-508/L T-7/51 E90X D20-C20-06 20.00 3 5.80 22.0 110.00 20.00 C 3.0 0.25 SR 34-508/L T-7/51 E90X D25-C20-06 25.00 4 5.80 25.0 120.00 20.00 C 2.5 0.29 SR 34-508/L T-7/51 E90X D32-W25-06 32.00 5 5.80 25.0 90.00 25.00 W 3.8 0.34 SR 34-508/L T-7/51 • For user guide see pages 542-548 (1) Number of inserts (2) C-Cylindrical, W-Weldon (3) Maximum ramping angle For inserts, see pages: QOMT-HQ (494) • SOMT-HQ (494) • XOMT-HQ (494) H690 EWN-07 90° Endmills Carrying H690 DC DCONMS Rd° WNMU 0704 Double-Sided Trigonal Inserts with 6 APMX Helical Cutting Edges LH OAL Designation DC CICT(1) APMX OAL LH DCONMS Shank(2) RMPX°(3) kg H690 EWN D032-03-W32-R07 32.00 3 7.00 110.00 48.0 32.00 W 2.0 0.56 SR M4X0.7IP15 BLD IP15/S7 SW6-T-SH H690 EWN D040-04-W32-R07 40.00 4 7.00 110.00 35.0 32.00 W 1.5 0.64 SR M4X0.7IP15 BLD IP15/S7 SW6-T-SH • Insert clamping screw must be lubricated every indexing. • Tightening torque 0.9 Nxm. • For user guide see pages 542-548 (1) Number of inserts (2) C-cylindrical, W-Weldon (3) Maximum ramping angle For inserts, see pages: H690 WNHU/WNMU 0705 (469) 16 ISCAR

Каталог Iscar токарный инструмент

Каталог Iscar токарный инструмент Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar инструментальная оснастка 2022

Каталог Iscar инструментальная оснастка 2022