Каталог Iscar инструментальная оснастка 2022 - страница 162

Навигация

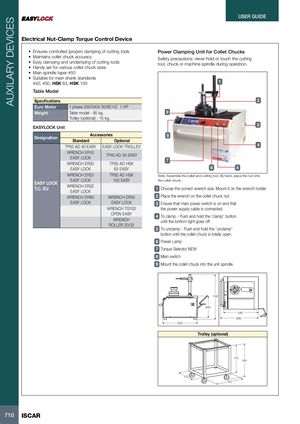

AUXILARY DEVICES USER GUIDE Electrical Nut-Clamp Torque Control Device • Ensures controlled (proper) clamping of cutting tools Power Clamping Unit for Collet Chucks • Maintains collet chuck accuracy Safety precautions: never hold or touch the cutting • Easy clamping and unclamping of cutting tools tool, chuck or machine spindle during operation. • Handy set for various collet chuck sizes • Main spindle taper #50 • Suitable for main shank standards #40, #50, HSK 63, HSK 100 1 Table Model Specifications 2 Euro Motor 1 phase 200/240V 50/60 HZ 1 HP Weight Table model - 85 kg. 9 Trolley (optional) - 15 kg. EASYLOCK Unit 3 Designation AccessoriesStandardOptional 8 TP50 AD 40 EASY EASY LOCK TROLLEY 4 WRENCH ER16EASY LOCK TP40 AD 30 EASY 7 WRENCH ER20 TP50 AD HSK EASY LOCK 63 EASY 6 5 WRENCH ER25 TP50 AD HSK Note: Assemble the collet and cutting tool. By hand, place the nut onto EASY LOCK EASY LOCK 100 EASY the collet chuck. T.C. EU WRENCH ER32EASY LOCK 1 Choose the correct wrench size. Mount it on the wrench holder. WRENCH ER40 WRENCH ER50 2 Place the wrench on the collet chuck nut. EASY LOCK EASY LOCK 3 Ensure that main power switch is on and that WRENCH TG100 the power supply cable is connected. OPEN EASY 4 To clamp - Push and hold the “clamp” button WRENCH until the bottom light goes off. ROLLER 20/32 5 To unclamp - Push and hold the “unclamp” button until the collet chuck is totally open. 6 Power Lamp 700 7 Torque Selector NEW 340 8 Main switch 9 Mount the collet chuck into the unit spindle. 500 700 340 540 600 500 Trolley (optional) 510 630 540 600 510 550 710 ISCAR

Каталог Iscar инструментальные блоки

Каталог Iscar инструментальные блоки Каталог Iscar токарный инструмент 2017

Каталог Iscar токарный инструмент 2017 Каталог Iscar монолитные фрезы 2022

Каталог Iscar монолитные фрезы 2022 Каталог Iscar расточные системы

Каталог Iscar расточные системы Каталог Iscar обработка канавок 2022

Каталог Iscar обработка канавок 2022 Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018